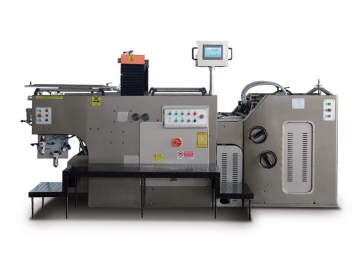

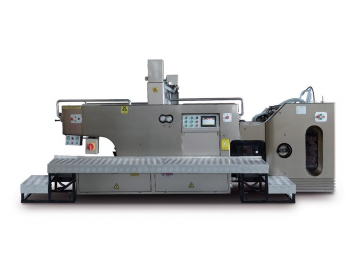

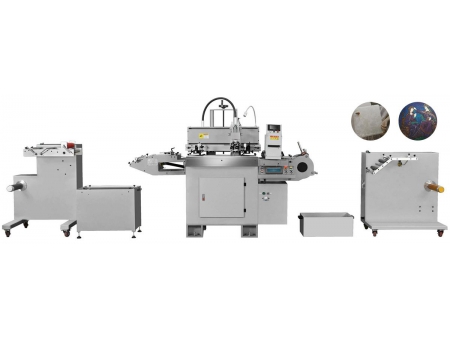

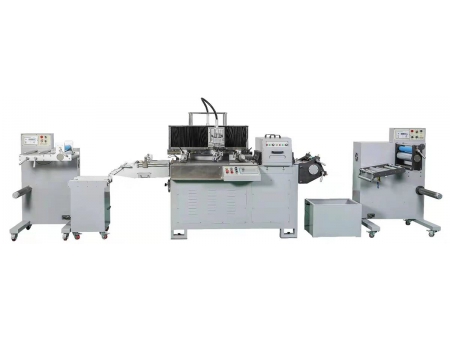

JB-720A/800A/1020A Fully Automatic Stop Cylinder Screen Printing Machine

Recommended application

JB-720A/800A/1020A fully automatic stop cylinder screen printing machines are designed with classic stop cylinder technology, featuring 3600pcs/h printing speed, accurate sheet positioning, high printing precision and low noise. They are suitable for the screen printing of ceramic and glass decals, advertising, package printing, labels, textile transfer, special process and many other industries.

With classic stop cylinder technology, if these machines are linked with rotary vane type screen printing dryer or infrared and ultraviolet dryer, UV curing machine and fully automatic paper stacker, a full automatic screen printing line can be used to enhance the working efficiency.

Technical parameters| Model | JB-720A | JB-800A | JB-1020A |

| Max. paper size | 720×500mm2 | 800×590 mm2 | 1020×720 mm2 |

| Min. paper size | 350×270mm2 | 350×270 mm2 | 560×350 mm2 |

| Max. printing size | 720×500 mm2 | 800×590 mm2 | 1020×710 mm2 |

| Paper thickness | 108-400g/m2 | 108-400g/m2 | 108-400g/m2 |

| Size of screen size | 880×880 mm2 | 1070×1070 mm2 | 1140×1280mm2 |

| Border | Less than 10mm | Less than 10mm | Less than 10mm |

| Printing speed | 1000-3600pcs/h | 1000-3300pcs/h | 1000-3000pcs/h |

| Power supply | 3P, 380V/50HZ | 3P, 380V/50HZ | 3P, 380V/50HZ |

| Installed power | 10.5KW | 10.5KW | 14.64KW |

| Total weight | 3500kg | 4000kg | 5500kg |

| Outline size(L×W×H) | 3300×2450×1690mm3 | 3480×2580×1690mm3 | 4150×2840×1700mm3 |

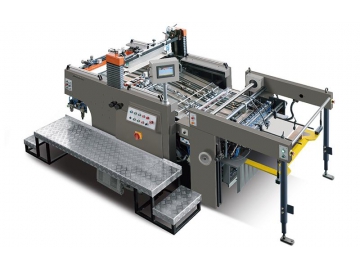

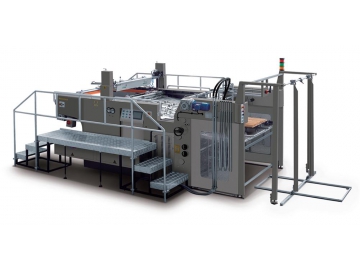

Features of JB-720A/800A/1020A fully automatic stop cylinder screen printing machine

Stop cylinder mechanism

The automatic stop cylinder guarantees that the front end of the printing substrates can be conveyed to the gripper with extreme high accuracy. Meanwhile, the gripper and side lays are both equipped with detecting sensor to monitor the location of the printing substrates, which effectively minimizes the reject rate of printing.

Transfer system

The vacuum absorption device under the feed board coordinates with the paper stacking and pressing structure guaranteeing smooth delivery of a variety of printing substrates.

Squeegee system

Two cams control the actions of the squeegee and flood bar respectively. The squeegee is equipped with a pneumatic pressure kept device, allowing for clearer printing image and more uniform ink layer.

Centralized lubrication system

Automatic lubrication for main transmission and main parts effectively enhance the use precision and prolongs the machine's life.

Screen structure

The screen frame can be pulled out not only facilitating the registration of substrates and the adjustment of feeding, but also making the cleaning of the cylinder and screen frame safer and faster. It is assembled with an ink dropping pan to prevent ink from spilling and being wasted.

Electrical control

PLC centralized control of the operation of the whole machine, standard configuration of touch screen and button dual operating system, provide simple operation and high degree of automation.