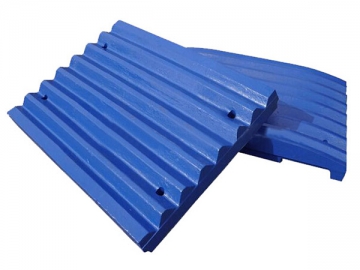

Jaw Plates

Parts Name: Jaw plate

Types: Fixed jaw plate, movable jaw plate

Applicable Machine: Jaw crushers

Materials: High manganese steel, super high manganese steel, ultrastrong manganese steel, modified high manganese steel

Applications: The crusher jaw plates are widely used in mining, smelting, building materials, road construction, railway construction, water conservancy and chemical industries for crushing various ores and bulky materials into medium grain size.

Customizable or not: Yes

Crusher Model: For jaw crushers in all kinds of models

Order Quantity: not limited

Principle: As the jaw crusher works, eccentric shaft drives the movable jaw to move up and down, and makes it close to the fixed jaw plates, thus crushing materials.

Introduction

Jaw plate, also called toothed plate is the key wear-resistant part of jaw crusher. A set of jaw plates generally consists of a movable plate and a fixed plate. They work together to crush materials. The crusher parts come in various profiles and sizes for different jaw crushers. They are mainly made of high manganese steel.

Jaw crusher comes with extensive applications. Due to the differences in crusher size, feeding particle size and material hardness, the compaction and impact forces on the jaw plates are different. HANDY can make jaw plates in all kinds of specifications from high manganese steels for applications in different working conditions.

Features

1. Our crusher jaw plates are fabricated from high manganese steel, ensuring excellent wear resistance and long service life.

2. Due to cold hardening technology, they come with exceptional hardness.

3. Water toughening treatment avoids spontaneous phase change which results in worse jaw plate performance.

4. Before delivery, all of our jaw plates must go through stringent tests to ensure high quality.

5. 24-hour camera monitoring system for each production process can maximize

| Model | Feed opening (mm) | Maximum feeding size (mm) | Discharge opening (mm) | Capacity (t/h) | Eccentric shaft speed (r/min) | Motor power (kw) |

| 250 × 400 | 210 | 20-60 | 5-20 | 290 | 15 | |

| 400 × 600 | 350 | 40-100 | 15-60 | 275 | 30 | |

| 500 × 750 | 425 | 50-100 | 40-110 | 250 | 55 | |

| 600 × 750 | 480 | 75-150 | 60-150 | 250 | 75 | |

| 600 × 900 | 500 | 65-180 | 65-160 | 250 | 55-75 | |

| 700 × 900 | 650 | 75-150 | 100-220 | 250 | 90 | |

| 750 × 1060 | 630 | 80-180 | 110-320 | 250 | 110 | |

| 870 × 1060 | 750 | 80-200 | 140-350 | 250 | 90 | |

| 900 × 1200 | 780 | 95-225 | 220-450 | 200 | 110 | |

| 1000 × 1200 | 850 | 195-265 | 250-500 | 200 | 110 |