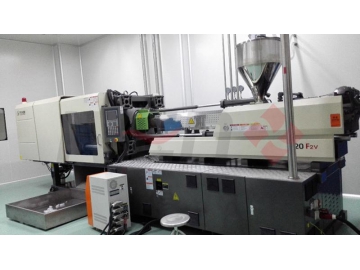

TYM-W3535 Liquid Silicone Injection Molding Machine

This liquid silicone injection molding machine is also called liquid silicone rubber baby nipple making machine or silicone baby nipple machine.

Features of Liquid Silcone Injection Molding Machine

1. Our horizontal liquid silicone rubber injection molding machine is highly efficient, energy saving, and requires low cost to operate.

2. The use of the precise cold runner LSR mould ensures the high quality and long lifetime of LSR products.

3. The liquid silicone rubber baby nipple making machine adopts permanent magnet synchronous servo motors with quick response. The output flow of the power mechanism matches the flow of the actuating mechanism, so there is no high-pressure throttling loss.

4. Quality oil pump, proportional valve and magnetic valve from world famous brands help guarantee excellent control of the hydraulic functions.

5. New TYM series controller, adjustable parameter settings, and multiple electronic rulers that monitor each action executed, can guarantee the reliability, stability and accuracy of the machine's operation.

6. Our self-developed direct pressure injection barrel is more suitable for the moulding process of the LSR material.

7. Our self-developed full stainless steel pumping unit and fixed displacement pump can guarantee accurate proportion of 1:1 (A:B) for feeding the material.

| Model Item | TYM-W3535 Note: Assuming the LSR density: 1.2g/cm3 |

| Injection unit | |

| The diameter of injection pail (mm) | 30 |

| The length of injection pail (mm) | 150 |

| Shot volume (theoretical) (ml) | 120 |

| Injection rate (ml/s) | 25 |

| Injection pressure (t) | 12.5 |

| Nozzle radius (mm) | R19 |

| Clamping unit | |

| Clamp force (t) | 95 |

| Opening stroke (mm) | 400 |

| The space between tie-bars (mm) | 350×350 |

| Min. Moldboard distance (mm) | 100 |

| Ejector stroke (mm) | 100 |

| Ejection force (t) | 7.8 |

| Others | |

| Pump pressure (mpa) | 25 |

| Pump motor power (kw) | 7.5 |

| Heating power (kw) | 9 |

| Machine dimension (l×w×h) (mm) | 5000×1200×1580 (including the dosing unit) |

| Mould orientation ring diameter (mm) | Φ100 |

| The specification of the dosing unit (kg) | 200kg/20kg |

| Machine weight (t) | 3.0 |