HYFP6.5-HYFP65 Nonwoven Geotextile

HAOYANG HYFP series geotextiles are nonwoven, spunbonded, continuous filament, coarse fiber polypropylene geotextiles that offer the consistent quality expected of spunbond geotextiles. The spunbond process is considered the fastest manufacturing method for nonwoven fabrics. As a result, spunbonding is considered to be more economical than other manufacturing methods such as needle punching staple fiber. During the spunbonding process extruded filaments are spun onto a collecting belt and bonded by applying heated rolls.It has superior tensile strength per weight.

Product Specifications| Tested Property | Unit | Test Method | HYFP6.5 | HYFP10 | HYFP16 | HYFP21 | HYFP30 | HYFP37.5 | HYFP45 | HYFP50 | HYFP56 | HYFP65 |

| Tensile Strength ≥ | kN/m | ASTM D 4595 | 6.5 | 10 | 16 | 21 | 30 | 37.5 | 45 | 50 | 56 | 65 |

| Tensile Elongation | % | ASTM D 4595 | 40~110 | |||||||||

| Trapezoidal Tear ≥ | kN | ASTM D4533 | 0.18 | 0.46 | 0.65 | 0.75 | 1.1 | 1.2 | 1.3 | 1.45 | 1.6 | 1.75 |

| CBR Burst Strength ≥ | kN | ASTM D 6241 | 1.2 | 2 | 2.5 | 3.8 | 5 | 5.6 | 7.2 | 8.7 | 9.1 | 9.4 |

| Grab Strength ≥ | KN | ASTM D 4632 | 0.2 | 0.75 | 1 | 1.6 | 2 | 2.5 | 3.5 | 4 | 4.35 | 4.8 |

| Grab Elongation | % | ASTM D 4632 | 50~120 | |||||||||

| Puncture Resistance | KN | ASTM D 4833 | 0.19 | 0.33 | 0.42 | 0.55 | 0.8 | 0.92 | 1 | 1.05 | 1.3 | 1.4 |

| Cone Drop Resistance | mm | BS EN 918 | 34 | 25.8 | 22.8 | 17.5 | 14 | 11.7 | 9.6 | 8.9 | 5.3 | 4.6 |

| Flow Rate(50mm) | l/m2/s | ASTM D 4491 | 130 | 105 | 85 | 80 | 78 | 45 | 38 | 32 | 27 | 22 |

| Permeability | m/s | ASTM D 4491 | 0.002 | |||||||||

| Apparent Opening Size O90 | mm | ASTM D 4751 | 0.26 | 0.21 | 0.16 | 0.11 | 0.08 | 0.08 | 0.08 | 0.07 | 0.07 | 0.06 |

| Thickness ≥ | mm | ASTM D 5199 | 0.9 | 1.25 | 1.4 | 1.8 | 2.2 | 2.8 | 3.5 | 3.8 | 4.3 | 4.8 |

| Mass Per Unit Area | g/m2 | ASTM D5261 | 100 | 150 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 1000 |

| Mass Variation | % | -5 | ||||||||||

| Width Variation | % | -0.5 | ||||||||||

| Chemical Resistance | PH 2~13 | |||||||||||

| Uv Resistance(3 Month Outdoor) | Strength Retention Rate≥70% | |||||||||||

| Typical Roll Width(40'HC) | m | 4.3 | 4.3 | 4.3 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | 4.5 | |

Materials: polypropylene

Regular sizes: 1M~4.5M WIDTH

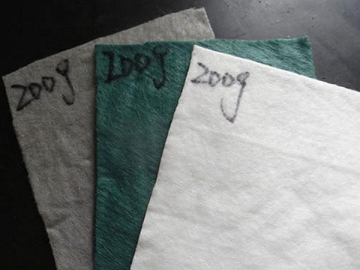

Color: Black, Black Green, Grey or White (as required)

Production ability: 20,000 m2/day

Due to the great physical properties and chemical stability of polypropylene, HYFP6.5—HYFP65 nonwoven geotextile is widely used in geotechnical engineering, especially in acidic or alkaline environments.

1. Applications in environmental protection engineering

Due to the fact that most construction sites in environmental protection engineering industries are located in strong alkaline environments, HYFP6.5—HYFP65 nonwoven geotextile is an essential material in the construction. The construction sites generally sit in tailing dams and dump leaching plants for diverse medals (gold, silver, copper, molybdenum, aluminum, magnesium, lead, zinc, and so on), landfills, special wastes landfills, flash landfills, ash dam pools, heap leaching fields, and red mud ponds. PE geotextiles, under alkaline conditions, are gradually corroded and decompose, lowering their efficiency and strength over time, leading to increased risks and project loss. That is why the chemical stability of PP geotextiles makes it a popular solution in these environments, guaranteeing the project quality and lower maintenance costs.

2. Applications in water conservancy projects

PP geotextile has a good stretching resistance, leading to its wide usage in strengthening, protection and filter inversion for reservoir damns, rivers and lakes, as well as providing a strong dams and less soil erosion. Combined with a geomembrane, PP geotextiles are used to manufacture compound geomembranes, and used in seepage control systems for water conservancy projects.

Cement alkaline can dissolve polyester geotextile in as little as six months, which can lead to significant hidden dangers in water conservancy projects, including loss of life and/property. As PP geotextiles do not degrade as quickly, they are a popular choice when direct contact with cement is needed.

3. Applications in transportation projects

PP nonwoven geotextiles are also widely used in transportation projects, as it can be used to strengthen and isolate, as well as inverse filtering for the subgrades of railways and highways. PP nonwoven geotextiles are also applied in the sliding layer and isolation layer for high-speed rail ballastless track, in the reinforced layer for airport apron and runway, harbor slope protection and other places, making it popular in traffic engineering. Thanks to its good alkali resistance, the physical properties will not be reduced when in direct contact with alkaline cement, thus playing a crucial role in its serving life.

HAOYANG HYFP series geotextiles are nonwoven, spunbonded, continuous filament, coarse fiber polypropylene geotextiles that offer the consistent quality expected of spunbond geotextiles. The spunbond process is considered the fastest manufacturing method for nonwoven fabrics. As a result, spunbonding is considered to be more economical than other manufacturing methods such as needle punching staple fiber. During the spunbonding process, extruded filaments are spun onto a collecting belt and bonded by applying heated rolls, leading to a better tensile strength per weight.

Features

1. Polypropylene has a small density-0.91g/m3 (polyester-1.38g/m3). Compared to polyester geotextile, PP geotextiles have a larger cover area under the same force.

2. Due to its special structure, polypropylene has a high resistance to acid and alkali mediums. Its alkaline resistance is far better than that of polyester. Polypropylene has a better protection, strengthening, water resistance and seepage resistance when it's used in underground environments with a strong acidity and basicity than polyester does.

3. Polypropylene fiber has a small surface friction coefficient, small friction between the fibers, and great wear resistance. Its anti-vibration friction performance is much better than that of polyester.

4. Polypropylene has a good hydrophobicity, and it is non-absorbent. When used in water drainage projects, it has a better performance than polyester.

5. HYFP6.5—HYFP65 nonwoven geotextile has a higher tensile strength than that of HYF4.5—HYF40 nonwoven geotextile, and it has a same vertical and horizontal tensile strength.

6. HYFP6.5—HYFP65 nonwoven geotextiles can achieve a compound of HYFP6.5—HYFP65 nonwoven geotextiles of different deniers, and has a better filtering performance.

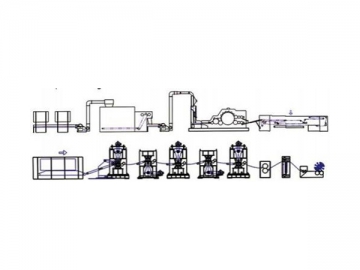

Haoyang adopts advanced spun bonded needle-punched geotextile manufacturing equipment from Italy and Germany, which helps to produces better PP nonwoven geotextiles than GB/T17639-2008, and the many technical parameters of its products are better than that of imported products.

Take 700g/m2 PP nonwoven geotextile as an example, and its technical parameters are as follows:

Tensile strength: > 52kN/m

Tearing strength: 1.8kN

Bursting strength: > 9kN

The technical parameters mentioned above are far better than that of P3—P26 nonwoven geotextile, satisfying the demanding requirements from the new standards for isolation layers in high-speed railway projects.

Haoyang is a leading environmental protection service provider, a manucturer, marketer and installer of geosynthtic products and service. We deliver consistancy of products and service to our customers through our expertise and professional team with the determination to serve our customers and protect our enviroment.

Our national approved R&D Center focuses on new material, product and project innovation; our team of expertise focuses on quality and customized products, giving us the strength to handle challenging projects to guarantee our clients' success.

This geotextile fabric is a continous filament needle punched coarse fiber polypropylene spunbond nonwoven gentextile, it has been widely used in Europe and America.

According to the weaving process, the product can also be called simply: geofabric; geofelt; pp geotextile; polypropylene spunbond geotextile; polypropylene spunbond nonwoven geotextile; pp continuous filament geotextile; polypropylene continous filament geotextile; pp filament geotextile; ; pp needle punched geotextile; polypropylene needle punched geotextile; pp nonwoven geotextile; polypropylene geotextile; polypropylene nonwoven geotextile; high strength geotextile.

According to the application, they can also be referred to as filter geotextile, protective geotextile, reinforced geotextile, and insulating geotextile.

Many Asia, Africa, Russia and australia customers request the contious filament needle punched non-woven fabric is polyester contious filament material, we can also provide, please check our products series .