Get in touch with us

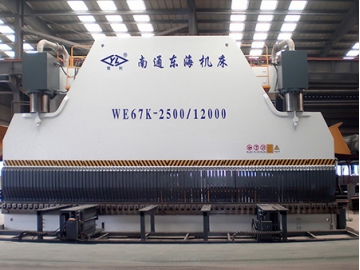

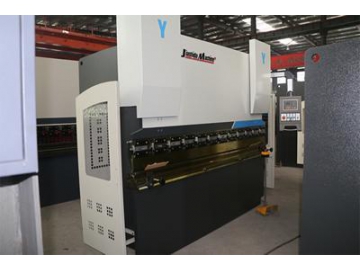

CNC Press Brake

Features

- Precision bending to provide a superior processing accuracy;

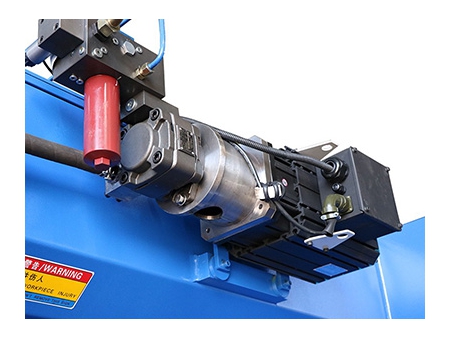

- Sliding block moves up and down by utilizing two hydraulic cylinders to control; Electro-hydraulic servo system is used to control the two cylinders for sliding block synchronization, ensuring a constant reliability;

- Using CNC controller from world famous brand DELEM to control Y-axis;

- Current and target positions of X, Y and V axes will be displayed;

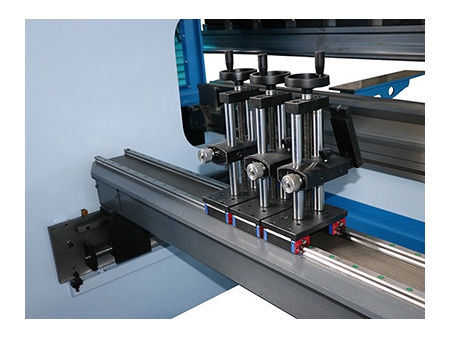

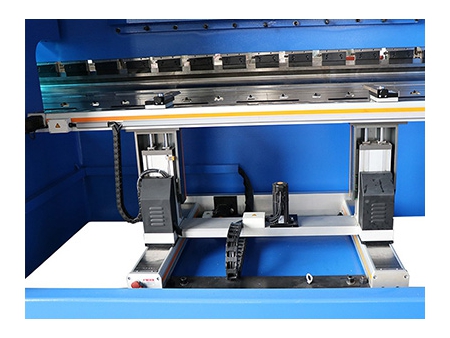

- Back gauge is controlled by servo motor, ensuring high positioning accuracy of X-axis;

- Compact structure, excellent sealing performance, high synchronization precision, long service life;

- Equipped with large diameter filling valve, featuring high speed and low consumption;

- Adopting HYTECH high pressure gear pump which can bear high pressure and produce low noise;

- Overload and overflow protection is outfitted to hydraulic system;

- The CNC press brake can be continuously operated under rated workload condition, guaranteeing a high precision;

- Various specifications including open height (daylight), throat depth and quantity of CNC axis are selectable according to your specific needs;

- Manual operation, semi-automatic operation and fully automatic operation are available;

- Can be configured with CNC port for synchronization of two or three machines;

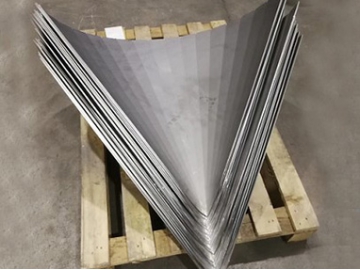

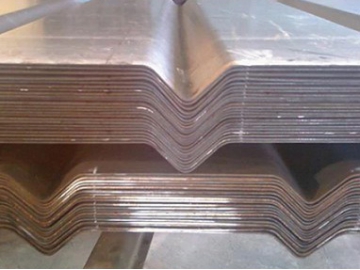

Applications

Details

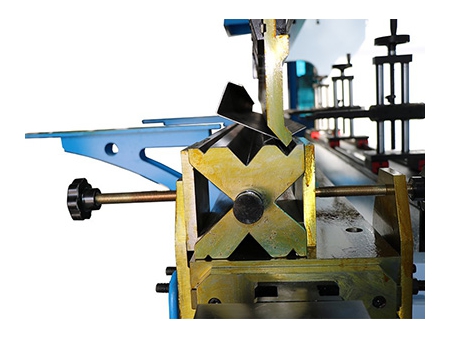

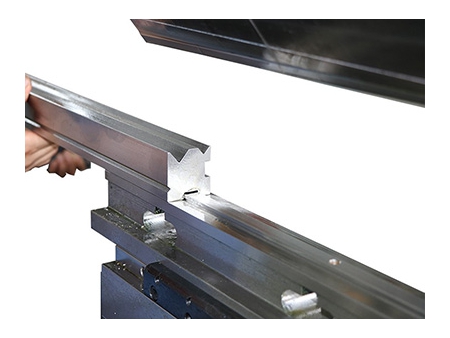

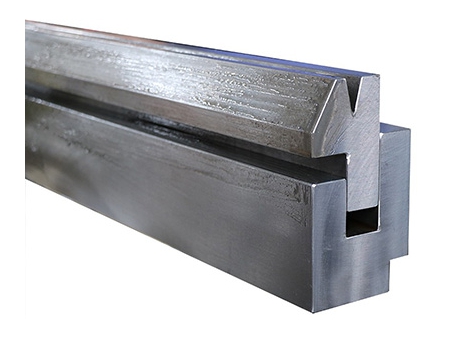

Standard 4-way die with multiple V openings

Standard 4-way die with multiple V openings  DELEM CNC controller

DELEM CNC controller  Precision hydraulic cylinder

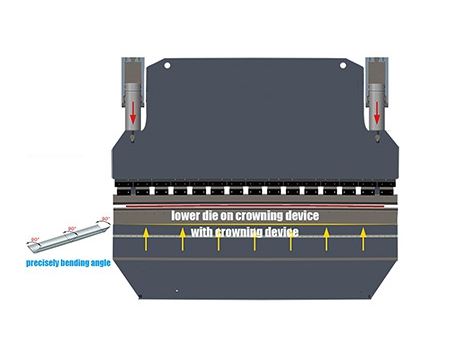

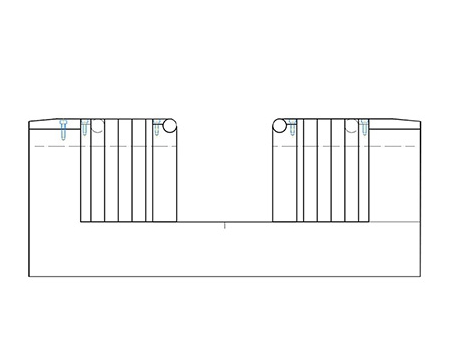

Precision hydraulic cylinder  CNC crowning system for deflection compensation

CNC crowning system for deflection compensation  Gear pump

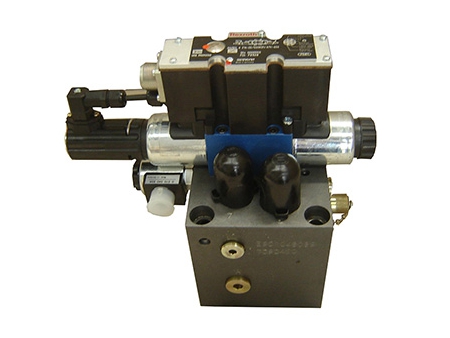

Gear pump  REXROTH proportional servo valve

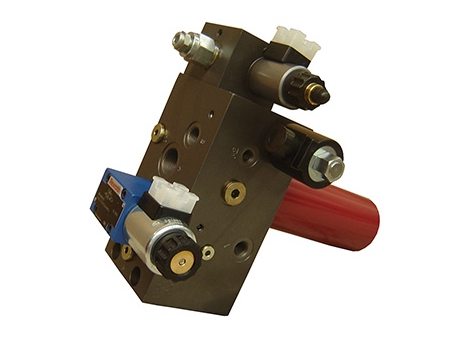

REXROTH proportional servo valve  REXROTH pressure valve

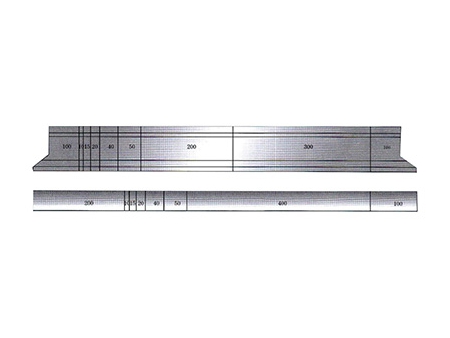

REXROTH pressure valve  CNC back gauge (X-axis), R-axis and Z-axis are manually adjusted

CNC back gauge (X-axis), R-axis and Z-axis are manually adjusted

Optional configurations

Servo motor, servo hydraulic pump

Servo motor, servo hydraulic pump  X-R-Z axes CNC back gauge

X-R-Z axes CNC back gauge  Quick change bottom die

Quick change bottom die  DA-53S, DA-56S, DA-58T, DA-66T CNC control system

DA-53S, DA-56S, DA-58T, DA-66T CNC control system  Bottom die and die holder

Bottom die and die holder  Adjustable bottom die

Adjustable bottom die  Segmented top punch

Segmented top punch  Oil cooler

Oil cooler

Specifications

| No. | Model | Unit | WE67K-63/2500 | WE67K-100/3200 | WE67K-125/3200 | WE67K-125/4000 | WE67K-160/3200 | WE67K-160/4000 |

| 1 | Nominal pressure | KN | 630 | 1000 | 1250 | 1250 | 1600 | 1600 |

| 2 | Bending width | mm | 2500 | 3200 | 3200 | 4000 | 3200 | 4000 |

| 3 | Distance between uprights | mm | 2050 | 2600 | 2600 | 3100 | 2500 | 3100 |

| 4 | Stroke | mm | 110 | 150 | 150 | 150 | 200 | 200 |

| 5 | Max. daylight | mm | 235 | 330 | 330 | 330 | 400 | 400 |

| 6 | Throat depth | mm | 250 | 320 | 320 | 320 | 320 | 350 |

| 7 | Working table length | mm | 2500 | 3200 | 3200 | 4000 | 3200 | 320 |

| 8 | Approaching speed | mm/s | 100 | 100 | 100 | 100 | 60 | 60 |

| 9 | Bending speed | mm/s | 8.5 | 8.5 | 8.5 | 8.5 | 6.5 | 6.5 |

| 10 | Returning speed | mm/s | 80 | 80 | 80 | 80 | 60 | 60 |

| 11 | Main motor power | KW | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| 12 | Oil pump | mr/r | 10 | 16 | 16 | 16 | 25 | 25 |

| 13 | Back gauge range | mm | 600 | 600 | 600 | 600 | 600 | 600 |

| 14 | Machine length | mm | 2600 | 3300 | 3300 | 4100 | 3300 | 4100 |

| 15 | Machine width | mm | 1400 | 1400 | 1400 | 1400 | 1550 | 1550 |

| 16 | Machine height | mm | 1950 | 2380 | 2380 | 2430 | 2630 | 2630 |

| 17 | CNC axis | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V |

| No. | Model | Unit | WE67K-200/3200 Servo | WE67K-200/4000 | WE67K-250/3200 | WE67K-250/4000 | WE67K-250/6000 | WE67K-300/4000 |

| 1 | Nominal pressure | KN | 2000 | 2000 | 2500 | 2500 | 2500 | 3000 |

| 2 | Bending width | mm | 3200 | 4000 | 3200 | 4000 | 6000 | 4000 |

| 3 | Distance between uprights | mm | 2500 | 3100 | 2600 | 3100 | 4800 | 3100 |

| 4 | Stroke | mm | 200 | 200 | 200 | 200 | 200 | 200 |

| 5 | Max. daylight | mm | 435 | 435 | 435 | 435 | 435 | 435 |

| 6 | Throat depth | mm | 320 | 320 | 320 | 320 | 320 | 350 |

| 7 | Working table length | mm | 3200 | 4000 | 3200 | 4000 | 6000 | 400 |

| 8 | Approaching speed | mm/s | 60 | 100 | 100 | 100 | 70 | 60 |

| 9 | Bending speed | mm/s | 6.5 | 8.5 | 8.5 | 8.5 | 7 | 6.5 |

| 10 | Returning speed | mm/s | 60 | 80 | 80 | 80 | 60 | 60 |

| 11 | Main motor power | KW | 15 | 15 | 18.5 | 18.5 | 18.5 | 220 |

| 12 | Oil pump | mr/r | 25 | 25 | 32 | 32 | 32 | 40 |

| 13 | Back gauge range | mm | 600 | 600 | 600 | 600 | 600 | 600 |

| 14 | Machine length | mm | 3300 | 4100 | 3300 | 4100 | 6200 | 4100 |

| 15 | Machine width | mm | 1650 | 1630 | 1750 | 1750 | 1850 | 1850 |

| 16 | Machine height | mm | 2930 | 3070 | 3070 | 3070 | 3360 | 3285 |

| 17 | CNC axis | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V |

| No. | Model | Unit | WE67K-400/3200 | WE67K-400/4000 | WE67K-400/6300 | WE67K-600/4000 | WE67K-600/6000 | WE67K-600/7000 |

| 1 | Nominal pressure | KN | 4000 | 4000 | 4000 | 6000 | 6000 | 6000 |

| 2 | Bending width | mm | 3200 | 4000 | 6300 | 4000 | 6000 | 7000 |

| 3 | Distance between uprights | mm | 2600 | 3100 | 4800 | 3100 | 4800 | 5600 |

| 4 | Stroke | mm | 250 | 250 | 250 | 300 | 300 | 300 |

| 5 | Max. daylight | mm | 520 | 520 | 520 | 600 | 600 | 600 |

| 6 | Throat depth | mm | 400 | 400 | 400 | 400 | 400 | 400 |

| 7 | Working table length | mm | 3200 | 4000 | 6300 | 400 | 6000 | 7000 |

| 8 | Approaching speed | mm/s | 60 | 60 | 70 | 70 | 70 | 70 |

| 9 | Bending speed | mm/s | 6.5 | 6.5 | 7 | 7 | 7 | 7 |

| 10 | Returning speed | mm/s | 60 | 60 | 60 | 60 | 60 | 60 |

| 11 | Main motor power | KW | 30 | 30 | 30 | 45 | 45 | 45 |

| 12 | Oil pump | mr/r | 50 | 50 | 50 | 80 | 80 | 80 |

| 13 | Back gauge range | mm | 600 | 600 | 600 | 600 | 600 | 600 |

| 14 | Machine length | mm | 3300 | 4100 | 6400 | 4200 | 6200 | 7200 |

| 15 | Machine width | mm | 2000 | 2000 | 2100 | 2600 | 2600 | 2600 |

| 16 | Machine height | mm | 3230 | 3430 | 3600 | 3750 | 4350 | 4570 |

| 17 | CNC axis | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V |

| No. | Model | Unit | WE67K-600/8000 | WE67K-700/7000 | WE67K-800/6000 | WE67K-800/7000 | WE67K-8000/8000 | WE67K-1200/8000 |

| 1 | Nominal pressure | KN | 6000 | 7000 | 8000 | 8000 | 8000 | 12000 |

| 2 | Bending width | mm | 8000 | 7000 | 6000 | 7000 | 8000 | 8000 |

| 3 | Distance between uprights | mm | 6200 | 5600 | 4800 | 5600 | 6200 | 6200 |

| 4 | Stroke | mm | 300 | 300 | 400 | 400 | 400 | 400 |

| 5 | Max. daylight | mm | 600 | 640 | 800 | 800 | 800 | 900 |

| 6 | Throat depth | mm | 400 | 500 | 500 | 500 | 500 | 1200 |

| 7 | Working table length | mm | 8000 | 7000 | 6000 | 7000 | 8000 | 8000 |

| 8 | Approaching speed | mm/s | 70 | 70 | 70 | 100 | 100 | 70 |

| 9 | Bending speed | mm/s | 7 | 7 | 7 | 8.5 | 8.5 | 7 |

| 10 | Returning speed | mm/s | 60 | 60 | 60 | 80 | 80 | 70 |

| 11 | Main motor power | KW | 45 | 55 | 74 | 74 | 74 | 30 |

| 12 | Oil pump | mr/r | 80 | 100 | 100 | 100 | 126 | 160 |

| 13 | Back gauge range | mm | 600 | 600 | 600 | 600 | 600 | 1000 |

| 14 | Machine length | mm | 8200 | 7100 | 6200 | 7100 | 8100 | 8300 |

| 15 | Machine width | mm | 2700 | 2850 | 3200 | 3200 | 3200 | 4100 |

| 16 | Machine height | mm | 4600 | 4650 | 4800 | 5000 | 5300 | 6720 |

| 17 | CNC axis | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V |

| No. | Model | Unit | WE67K-2000/10000 | WE67K-2500/12000 | WE67K-3000/14000 | WE67K-1000/10000 |

| 1 | Nominal pressure | KN | 20000 | 25000 | 30000 | 10000 |

| 2 | Bending width | mm | 10000 | 12000 | 14000 | 10000 |

| 3 | Distance between uprights | mm | 7800 | 9050 | 10500 | 7800 |

| 4 | Stroke | mm | 400 | 300 | 600 | 400 |

| 5 | Max. daylight | mm | 920 | 900 | 1900 | 800 |

| 6 | Throat depth | mm | 600 | 600 | 1200 | 600 |

| 7 | Main motor power | KW | 110 | 45 | 165 | 90 |

| 8 | CNC axis | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V | Y1-Y2-X V |

Related products

Send Message

Most Recent

More

Other Products

Videos