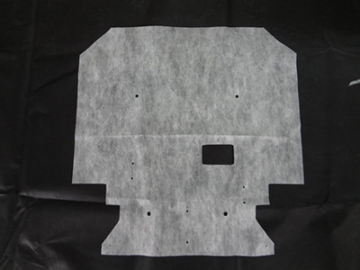

Custom Fit Seat Cover

As a professional integrated seat cover supplier, Dongping Plastic has over 10 years of experience in car seat cover manufacturing, including front seat covers, rear seat covers, armrest covers and related plastic parts. The cover materials provided by us include leather and vinyl. We also provide OEM services for car manufacturers, truck manufacturers, bus manufacturers and manufacturers of other vehicles and accessories. We carefully choose raw material suppliers, ensuring that all leather, artificial leather and vinyl is of the best possible quality, and all products must pass a performance test to ensure the final quality. Tests are carried out according to NES standards, ASTM standards, and GB standards, ensuring the car seat covers can be used not only in cars, but alo on high speed railways and planes. With a number of advantages in product design, quality, and mass production capabilities, we have 3 designers to help with product development. Customers need only provide a blueprint, and we will analyze it using a professional catia software for a sample production. Dongping Plastic has an exceptional production capability due to our factory being outfitted with 4 automatic cutting machines and over 100 sewing machines used for manufacturing of car seat covers at a monthly output of 1.3 million pieces.

- Fuji-seatSince 2004, Dongping Plastic has been providing car seat covers for Fuji-seat from Japan, totaling almost 100 million products. The supporting automobile types are PICO, MATERIA, COPEN, and SIRION.

- ToyotaWe are quite proud to be chosen by Toyota. We started the production of car seat covers for Toyota Corollas October 2018.

- X-TRAILWe were selected to produce car seat cover for Nissan’s X-trail in September of 2018. By the end of 2018, we had produced 0.6 million pieces.

Feature

We have passed ISO/TS16949 auto quality certification system. Our car seats are nontoxic, odorless, durable and feature an excellent toughness. They have an expected useful life of up to 20 years. We will test each batch of products prior to shipment. If the products are qualified, we will issue certificates with shipment.

| Item | Technical standard | Testing methods | Testing standard |

| Appearance | Correct materials and sewing Clean, tidy and not wrinkled No needle hole, no floats and no thread | visual inspection | —— |

| Thickness | 0.6±0.2mm | 100mm*100mm | NES M0154 |

| Weight | 148±14.8g/㎡ | 250mm*250mm | NES M0154 |

| Tensile strength | ≥245N/50mm | 50mm*250mm Testing speed: 200mm/min | NES M0154 |

| Tear strength | ≥39N | 50mm*240mm Testing speed: 200mm/min | NES M0154 |

| Seam Strength | ≥245% | 200mm*100mm stitch: 23B Distance from seam: 6 or 8mm Distance between stitches: 5±0.5mm Thread: polyester 8# | NES M0154 |

| Seam fatigue | ≤2.2mm | 100mm*100mm stitch: 23B Distance from seam: 6 or 8mm Distance between stitches: 5±0.5mm Thread: polyester 8# | NES M0154 |

| Fracture rate of seam 100 stitches | ≤5% | 50mm*550mm stitch: 21B Distance from seam: 8mm Distance between stitches: 5±0.5mm Thread: polyester8# | NES M0154 |

| Elongation in constant weight 3KG | — | 50mm*250mm Weight: 29.4N Hanging time: 5min Distance from marking line: 100mm Fixture is at the outside of the marking line about 7mm | NES M0154 |

| Residual contraction rate (I)10KG | ≤10% | 50mm*250mm Weight:98N Hanging time: 5min Distance from marking line: 100mm Fixture is at the outside of the marking line about 7mm | NES M0154 |

| Wear resistance (I)(grade) | not broken | d=140mm speed: 60 or 70rpm weight: 4.9N (500g) The distance between cleaner's nozzle and material 5mm | NES M0154 |

| Combustion | ≤80mm/min | 100mm*340mm | NES M0154 |

| Abrasion fastness | ≥4 grade | 80mm*250mm weight: 200g 100times | NES M0154 |

| Pilling | ≥3 grade | 100mm*120mm (2) Time: 5h Speed: 60±2 | NES M0154 |