Elliptical Head (EHA/EHB)

Elliptical Vessel Head, Elliptical Tank Head, Custom Head for Pressure Vessel, Customized Storage Tank Head, Pressure Container Head Customization

Weide takes a total area of 30 thousand m2. Our head forming is the most advanced one in the world. We have now independently developed 6600t, 3000t, and 680t fully automatic double-acting hydraulic presses, 10m, 4m, and 3m cold metal spinning machines, 4.5m hot metal spinning machines, and other supporting equipment and molds. We have comprehensive , allowing Weide to produce pressure vessel heads of all shapes, specifications, and materials.

| No. | Nominal diameter DN/mm | Total depth H/mm Tolerance | Roundness | Degree of convexity | Degree of concavity | Height of the straight edge |

| Standard | -0.2%~0.6%DN | ≤ 0.5%DN; ≤ 25mm | ≤ 1.25%Di | ≤ 0.625% Di | -5% ~10%h | |

| 1 | 300 | 100 | ≤ 1.5 | ≤ 3.75 | ≤ 1.88 | 25 |

| 2 | 350 | 113 | ≤ 1.75 | ≤ 4.38 | ≤ 2.19 | 25 |

| 3 | 400 | 125 | ≤ 2 | ≤ 5 | ≤ 2.5 | 25 |

| 4 | 450 | 138 | ≤ 2.25 | ≤ 5.63 | ≤ 2.81 | 25 |

| 5 | 500 | 150 | ≤ 2.5 | ≤ 6.25 | ≤ 3.13 | 25 |

| 6 | 550 | 163 | ≤ 2.75 | ≤ 6.88 | ≤ 3.44 | 25 |

| 7 | 600 | 175 | ≤ 3 | ≤ 7.5 | ≤ 3.75 | 25 |

| 8 | 650 | 188 | ≤ 3.25 | ≤ 8.13 | ≤ 4.06 | 25 |

| 9 | 700 | 200 | ≤ 3.5 | ≤ 8.75 | ≤ 4.38 | 25 |

| 10 | 750 | 213 | ≤ 3.75 | ≤ 9.38 | ≤ 4.69 | 25 |

| 11 | 800 | 225 | ≤ 4 | ≤ 10 | ≤ 5 | 25 |

| 12 | 850 | 238 | ≤ 4.25 | ≤ 10.63 | ≤ 5.31 | 25 |

| 13 | 900 | 250 | ≤ 4.5 | ≤ 11.25 | ≤ 5.63 | 25 |

| 14 | 950 | 263 | ≤ 4.75 | ≤ 11.88 | ≤ 5.94 | 25 |

| 15 | 1000 | 275 | ≤ 5 | ≤ 12.5 | ≤ 6.25 | 25 |

| 16 | 1100 | 300 | ≤ 5.5 | ≤ 13.75 | ≤ 6.88 | 25 |

| 17 | 1200 | 325 | ≤ 6 | ≤ 15 | ≤ 7.5 | 25 |

| 18 | 1300 | 350 | ≤ 6.5 | ≤ 16.25 | ≤ 8.13 | 25 |

| 19 | 1400 | 375 | ≤ 7 | ≤ 17.5 | ≤ 9.38 | 25 |

| 20 | 1500 | 400 | ≤ 7.5 | ≤ 18.75 | ≤ 9.38 | 25 |

| No. | Nominal diameter DN/mm | Total depth H/mm Tolerance | Roundness | Degree of convexity | Degree of concavity | Height of the straight edge Tolerance |

| Standard | -0.2%~0.6%DN | ≤ 0.5%DN; ≤ 25mm | ≤ 1.25%Di | ≤ 0.625% Di | -5% ~10%h | |

| 21 | 1600 | 425 | ≤ 8 | ≤ 20 | ≤ 10 | 25 |

| 22 | 1700 | 450 | ≤ 8.5 | ≤ 21.25 | ≤ 10.63 | 25 |

| 23 | 1800 | 475 | ≤ 9 | ≤ 22.5 | ≤ 11.25 | 25 |

| 24 | 1900 | 500 | ≤ 9.5 | ≤ 23.75 | ≤ 11.88 | 25 |

| 25 | 2000 | 525 | ≤ 10 | ≤ 25 | ≤ 12.5 | 40 |

| 26 | 2100 | 565 | ≤ 10.5 | ≤ 26.25 | ≤ 13.13 | 40 |

| 27 | 2200 | 590 | ≤ 11 | ≤ 27.5 | ≤ 13.75 | 40 |

| 28 | 2300 | 615 | ≤ 11.5 | ≤ 28.75 | ≤ 14.38 | 40 |

| 29 | 2400 | 640 | ≤ 12 | ≤ 30 | ≤ 15 | 40 |

| 30 | 2500 | 665 | ≤ 12.5 | ≤ 31.25 | ≤ 15.63 | 40 |

| 31 | 2600 | 690 | ≤ 13 | ≤ 32.5 | ≤ 16.25 | 40 |

| 32 | 2700 | 715 | ≤ 13.5 | ≤ 33.75 | ≤ 16.88 | 40 |

| 33 | 2800 | 740 | ≤ 14 | ≤ 35 | ≤ 17.5 | 40 |

| 34 | 2900 | 765 | ≤ 14.5 | ≤ 36.25 | ≤ 18.13 | 40 |

| 35 | 3000 | 790 | ≤ 15 | ≤ 37.5 | ≤ 18.75 | 40 |

| No. | Nominal diameter DN/mm | Nominal thickness | Total depth H/mm Tolerance | Roundness | Degree of convexity | Degree of concavity | Height of the straight edge |

| Standard | -0.2%~0.6%DN | ≤ 0.5%DN; ≤ 25mm | ≤ 1.25%Di | ≤ 0.625% Di | -5% ~10%h | ||

| 159 | 4 | 65 | 25 | ||||

| 5 | 25 | ||||||

| 6 | 25 | ||||||

| 8 | 25 | ||||||

| 219 | 5 | 80 | 25 | ||||

| 6 | 25 | ||||||

| 8 | 80 | ≤ 1.1 | ≤ 2.54 | ≤ 1.27 | 25 | ||

| 273 | 6 | 93 | 25 | ||||

| 8 | 25 | ||||||

| 10 | 25 | ||||||

| 12 | 25 | ||||||

| 325 | 6 | 106 | 25 | ||||

| 8 | 25 | ||||||

| 10 | 25 | ||||||

| 12 | 25 | ||||||

| 377 | 8 | 119 | 25 | ||||

| 10 | 25 | ||||||

| 12 | 25 | ||||||

| 14 | 25 | ||||||

| 426 | 8 | 132 | ≤ 2.0 | 5.07 | 2.54 | 25 | |

| 10 | 25 | ||||||

| 12 | 25 | ||||||

| 14 | 25 |

Notes:

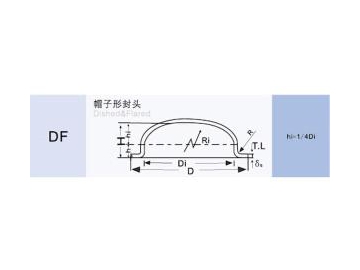

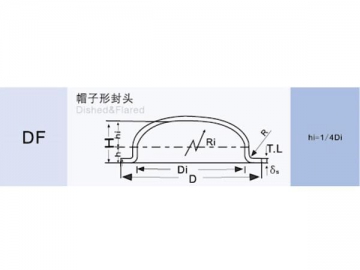

a. Total depth of head = depth of curved edge straight edge (1/4Di straight edge)

b. Longitudinal folds are not allowed on the straight edge of heads

Related products

Send Message

Most Recent

More

Other Products

Videos