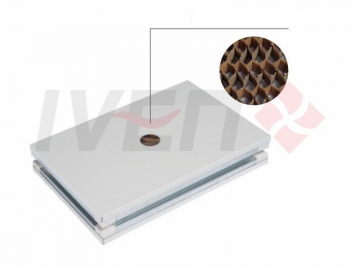

Honeycomb Board Production Line

The honeycomb board production line is designed to accommodate the production of honeycomb board by innovation based on traditional sheet machinery.

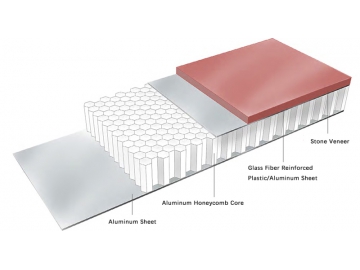

Plastic honeycombboard produced by this honeycomb board production line is a new type decoration material. As a new type, energy-saving and eco-friendlydecorative material, the plastic honeycomb board is widely used for makingbillboards, suspended ceilings, decorative boards, and more. The specialstructure allows the honeycomb panel to have high strength and low cost aswell. It features light weight, high intensity. Stable property, thermalinsulation, heat insulation, shockproof and so on.

Specifications

Plastichoneycomb board Category: For buffering and for packaging.

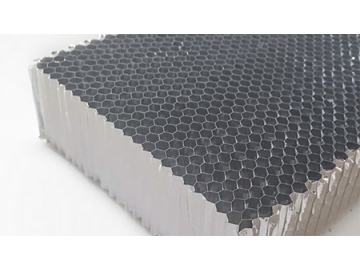

The hole size : 6mm and 8mm for the round core board;

3.6mm,6mm and 8mm for the hexagonalcore;

8mm for the PCcore.

Features of Plastic Honey Board

The honeycomb board offershigh strength-weight ratio, strong compression and shock resistance, lowthermal conductivity, light weight, sound insulation, moisture proofingproperty and stable performance within a wide temperature range.

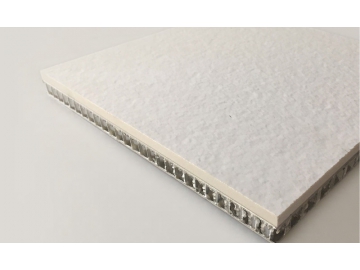

1. The honeycomb panel is flat, and easy to install.

2. Large board available

3. The honeycomb core board helps ensure heat preservation.

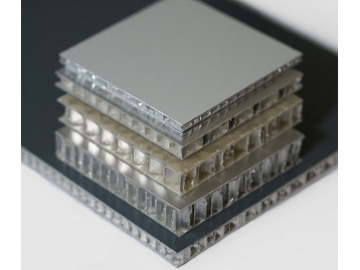

4. The board comes in rich colors and a variety of surface treatment.

5. High quality materials and advanced technology guarantee great durability ofthe honeycomb board.

Features of Honeycomb Board Production Line

1. This honeycomb board production line can produce boards with high planeness.

2. It is easy and convenient to install and maintain.

3. The boards produced by this honeycomb board production line are light in weight and strong in intensity.

4. Various colors and surface treaments are available.

5. This honeycomb board production line can produce board in large area.

6. The honeycomb core material used is helpful in improving thermal insulation in space.

7. As a result of the high quality and advanced processing techniques used in this honeycomb board production line, the honeycomb board is durable in use.

8. We provide customized processing to satisfy the personalized needs of customers.

9. The different installation system can accommodate different schemes.

Applications

1. The honeycomb board was first used in the aerospace industry and is now extensively used in building fields like decoration, curtain walls, roofs, floors and industrial departments like cars, trains, ships, light rails, metros, elevator sand so on.

2. With the special structure of papery honeycomb board, its resistance to pressure has been improved and the cost can be saved. As a result, the honeycomb board produced by this honeycomb board production line is used in the production of various trays, pads, packing plates, packing boxes, etc.

Thank you for visiting our website. New Wanda is a major manufacturer and supplier of honeycomb board production line, based in