VOC Emission Test Chamber

1. The VOC test chamber provides standard testing environment to determine the VOC emission rate and emission characteristics of interior decoration materials and products. Based on the test report, we can:

- Determine the impact of environmental variables on the VOC emission rate and emission characteristics.

- Classify the level of products and materials according to the emission characteristics

- Develop and adjust indoor air pollution models

- Evaluate the IAQ (Indoor Air Quality) according to the pollution data and test report

2. As being a significant means of VOC emission test, the VOC emission chamber finds a wide application in interior decoration, office furniture, engineered wood, carpets, plastics, leather, textile, toys and more.

- Engineered wood

- Leather

- Textile

- Plastics

- Toys

The coated stainless steel wall improves the adsorption capacity of test chamber for high-boiling-point materials and polar compounds. The recovery rate of tetradecane and 4-phenyl-1-cyclohexene can achieve more than 80%.

The patent is about how to deal with the connection surface between VOC emission chamber and the testing object. The technology helps to reduce the surface adhesive force, largely reducing VOC’s adhesiveness on chamber’s interior wall. In this way, the testing result of samples stored in the sampling bag is more close to the result of testing object in chamber, and the testing precision of emission chamber is largely improved.

- Processed stainless steel surface

- Unprocessed stainless steel surface

| Model | | |||||||||||||

| Environment temperature | 5℃-35 ℃ | |||||||||||||

| Environment humidity | ≤90%RH | |||||||||||||

| Environment requirements | With no pollution source, TVOC ≤500ug/m³ | |||||||||||||

| Size of climate chamber | D560×W300 ×H300 | D630×W400 ×H400 | D700×W600 ×H600 | D1020×W700 ×H700 | D1580×W800 ×H800 | D910×W1000 ×H1100 | D2000×W1100 ×H900 | |||||||

| Temperature adjustment range | 15℃- 40 ℃,more than 250 ℃ for high-temperature cleaning | |||||||||||||

| Humidity adjustment range | 40 - 60%RH (20 - 30℃) | |||||||||||||

| Pressure | 10±5pa | |||||||||||||

| Temperature fluctuation | ±0.3 ℃ | |||||||||||||

| Temperature deviation | ±0.5 ℃ | |||||||||||||

| Humidity fluctuation | ±2.5%RH | |||||||||||||

| Humidity deviation | 3% | |||||||||||||

| Air exchange rate | 0.2 - 2 times/h, ±5% | |||||||||||||

| Air velocity | 0.1m/s - 0.3m/s | |||||||||||||

| Power supply | AC 380V/50Hz/ Three-phase four-wire/ five-wire | |||||||||||||

| Start-up power | 5kw | 6kw | 8kw | 10kw | 15kw | 15kw | 20kw | |||||||

- Interior structure

- Sampling and testing holes (The hole number can be customized)

- High-temperature catalyst container

- Control System

The control system provides multiple languages.

Operation interface, Testing data, Curve graph, Malfunction alarm, Operation setting, Program setting

- Interior structure

- Interior structure

- Sampling and testing holes

- High-temperature catalyst container

- Operation interface

- Testing data

- Curve graph

- Malfunction alarm

- Operation setting

- Program setting

Testing Methods

1. The air is first processed by compressor to remove solid particles, formaldehyde and volatile organic compounds, and then enters into the test chamber.

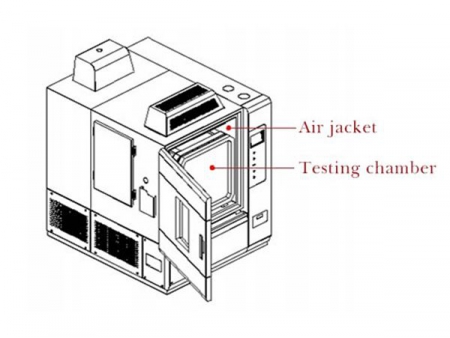

2. The climate chamber is designed with an air jacket for conditioning the temperature in testing chamber.

3. By adopting dew point method, the humidity of climate chamber is well regulated and controlled.

| GB18580-2001 | Indoor Decorating and Refurbishing Materials-Limit of Formaldehyde Emission of Wood-Based Panels and Finishing Products |

| GB18584-2001 | Indoor Decorating and Refurbishing Materials-Limit of Harmful Substances of Wood Based Furniture |

| GB18587-2001 | Indoor Decorating and Refurbishing Materials-Limitations of Harmful Substances Emitted From Carpets, Carpet Cushions and Adhesives |

| ASTM D6007-02 | Standard Test Method for Determining Formaldehyde Concentration in Air from Wood Products Using A Small Scale Chamber |

| ENV717-1 | Wood-Based Panels. Determination of Formaldehyde Release. Formaldehyde Emission by the Chamber Method. |

| EN13419-1 | Building Products. Determination of the Emission of Volatile Organic Compounds. Emission Test Chamber Method |

| HJ 571-2010 | Technical Requirement for Environmental Labeling Products Wood Based Panels and Finishing Products |

| HJ 566-2010 | Technical Requirement for Environmental Labeling Products Wooden Toys |

| ASTM D5116-97 | Standard Guide for Small-Scale Environmental Chamber Determinations of Organic Emissions from Indoor Materials/Products |

| ASTM D6330-98 | Standard Practice for Determination of Volatile Organic Compounds (Excluding Formaldehyde) Emissions from Wood-Based Panels Using Small Environmental Chambers Under Defined Test Conditions |

| ASTM D6670-01 | Standard Practice for Full-Scale Chamber Determination of Volatile Organic Emissions from Indoor Materials/Products |

| ASTM E1333-96 | Standard Test Method for Determining Formaldehyde Concentrations in Air and Emission Rates from Wood Products Using a Large Chamber |