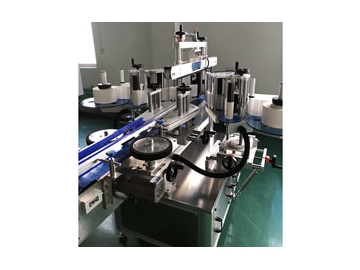

AS-P04 Top and Base Labeling Machine

This top base labeling machine was developed for the application of self-adhesive labels onto the top and base of various products simultaneously. It features a maximum production speed of 120 pcs/min. Optional coding machines and industrial inkjet printers can be installed on the labeling head to print the production date, batch number, bar code, and more information on the label.

Applications

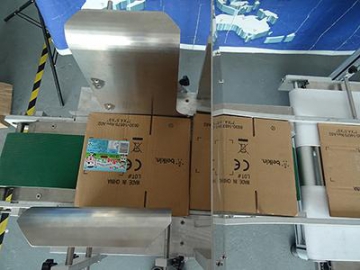

- Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

- Applicable products: products with flat surfaces including cartons and paper boxes.

- Applicable industries: paper, printing, packaging, garment, pharmaceutical, food, electronics, hardware, plastic, chemical, etc.

Samples

Specification

| Model | AS-P04 |

| Label stop accuracy | ±1mm |

| Production speed | 60-120 pcs/min |

| Product length | 20mm~400mm |

| Product width | 20mm~200mm |

| Product height | 10mm~200mm |

| Label length | 20mm~100mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 2200mm x 980mm x 1600mm |

| Weight | 150Kg |

Details of Top &Base Labeling system

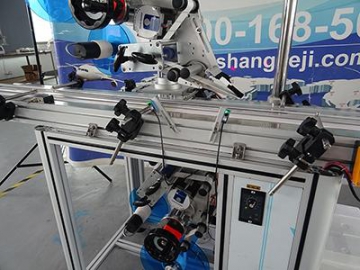

Photoelectric sensor

Photoelectric sensor

The labeling machine is equipped with a photoelectric sensor made by Sick which features high precision and high reliability. Touch screen:

Touch screen:

Controlled by PLC, the interface is convenient to use. With just a tap of its touch screen, you can easily access various functions and parameters for your product needs. Automatic separating equipment:

Automatic separating equipment:

It is designed to separate the workpiece so as to minimize labor costs and improve productivity. Two labeling heads: They can apply the self-adhesive label on the top and base of various products simultaneously.

Two labeling heads: They can apply the self-adhesive label on the top and base of various products simultaneously.- Easy to adjust: The 6DOF adjustable seat enables quick changeover between different products.

Related products

Send Message

Most Recent

More

Other Products

Videos