TJ300 Copper Flat Wire Line

Request a Quote

Continuous Extrusion Machine for Copper Wire, Strip and Flat Wire

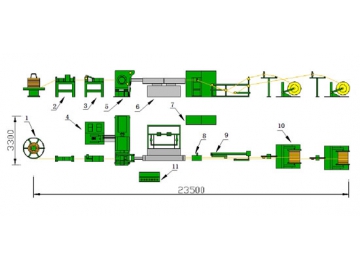

1. Payoff Machine 2. Straightening Machine 3. Cutting Machine 4. Continuous Rotary Extrusion Machine 5. Cooling and Drying System 6. Meter Counter 7. Guide Pulley 8. Take-up Machine 9. Hydraulic and Lubrication System 10. Electric Control Cabinet 11. Operation Console

The flat copper wire continuous rotary extrusion line adopts TJ300 series continuous extrusion machine as the main unit. By exchanging the extrusion die, it can be utilized to produce different types of end products, including pure copper flat wires, silver coated copper wire, as well as round shaped and profile wires. The extruded wire stock is extensively used to form the enamelled transposed conductor, paper covered wire, silk covered wire, electric cable and wire, etc.

Technical Specifications

| Main Functional Unit: Continuous Extrusion Equipment | |

| Model | TJ300 |

| Nominal Diameter of Extrusion Wheel | 300 mm |

| Rated Rotation Speed | 11 RPM |

| Power of Main Motor | 90kW/1000 RPM |

| Feed Stock (Copper Rod) | |

| Diameter | Φ12.5 mm |

| Diameter Tolerance | ±0.2mm |

| Yield Strength | 160MPa (Oxygen-free Copper Rod Produced by Upward Casting Process) |

| End Product : Flat Copper Wires | |

| Sectional Area Range | 10-250mm² |

| Max. Width | 45mm |

| Standard | Conforms to GB5585.1-85 standard |

| Entire Production Line | |

| Average Output | 200-450kg/h |

| Installed Capacity | 380V, 3 phase, 115KVA |

| Flash Amount | 1-3% |

| Workshop | |

| Minimum Dimension | Length: 30m, Width: 7 m, Height: 4 m |

| Cooling Water | 40 m3/h (Cooling Tower) |

| Compressed Air | 0.7 MPa, 1 m3/min |

| Operator | 2 |

Main Components of the Production Line

| Rod Material Payoff Machine | 1 set |

| Copper Rod Straightening Machine | 1 set |

| Copper Rod Cutting Machine | 1 set |

| Copper Continuous Extrusion Machine | 1 set |

| Cooling and Oxidation Prevention System (with Blow-drying Function ) | 1 set |

| Meter Counter (with Swing Arm) | 1 set |

| Takeup Machine (800 mm) | 2 sets |

| Electrical Control System (with Touch Screen) | 1 set |

| Hydraulic and Lubricating System | 1 set |

Accessories Included

| Extrusion Wheel | 3 pcs |

| Die Cavity | 3 pcs |

| Extrusion Die | 10 pcs |

| Mould Base | 10 pcs |

| Oil Seal | 1 set |

| Scraper | 3 pcs |

Features

- To suit clients' individual demands, this range of continuous rotary extrusion line for flat copper wires is especially designed with online hardening and finishing units, so as to produce hard copper wires.

- With a special extrusion die, TJ300 continuous rotary extrusion equipment is able to extrude two wires synchronously with only one feeding copper rod. This effectively reduces the pressure inside the die cavity, which ensures long lifespan of the extrusion die. Also, the design improves production efficiency.

- Operated by only two operators, our range of continuous rotary extrusion line largely reduces labor intensity and labor cost, thus production cost is reduced accordingly.

Continuous Rotary Extrusion, Wire Extruder, Copper Extrusion Line, Continuous Rotary Extrusion Equipment Manufacturer