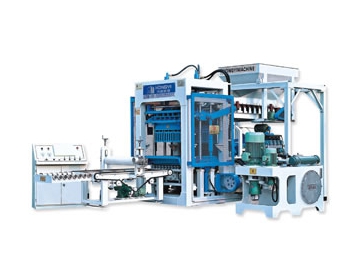

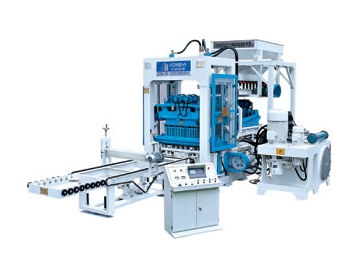

Zenith 844 Multilayer Block Machine

Application

The Zenith 844 multilayer block machine is specially designed to manufacture blocks with a height ranging from 50mm to 500mm. The machine can easily produce high quality paver brick, curbstone, and other landscape products.

Overviews

The 844 block making machine is outstanding multilayer block making equipment.

The Model 844 is a fully automatic and stationary multilayer block making machine, the economic equipment of high output, high quality and producing paver brick. This equipment is designed by Germany Zenith, characterized by high performance, easy operation and low maintenance cost. The touch screen uses visualized menu navigation, making all the operating function easy and straightforward.

Thanks to the modular production system, all the processes from raw material to finished product of the products can be automatically completed.

This block making machine is equipped with intelligent data storage system to transport and cure products, and the stacking of finished products meets the requirement of direct transportation.

During installation and debugging stages, QGM will send Zenith working team to supply full assistance to ensure your smooth operating of the production equipment.

Technical parametersBlock specifications and product height

| Maximum | 500 mm |

| Minimum | 50 mm |

| Max.height of brick stack | 640 mm |

| Max.production area | 1240x1000 mm |

| Pallet size (standard) | 1270x1050x125 mm |

| Hopper volume of base material | About 2100 L |

| Machine weight | |

| With pigments device | About 14 T |

| With conveyor, operating platform, hydraulic station, pallet warehouse, etc | About 9 T |

| Machine size | |

| Max.total length | 6200 mm |

| Max.total height | 3000 mm |

| Max.total width | 2470 mm |

| Machine technical parameters/energy consumption | |

| Vibrating system | |

| Vibration table | Two parts |

| Vibration table | Max.80 KN |

| Top vibration | Max.35 KN |

| Hydraulic system: composite loop | |

| Total flow | 83 L/min |

| Operating pressure | 18 MPa |

| Energy consumption | |

| Max.power | 50 KW |

| Control system | Siemens S7-300 (CPU315) |

Technical advantages

Intelligent operating:

This equipment adopts PLC intelligent interactive system, which is controlled by a 15 inch touch screen and PLC, to operate full automatically, semi automatically or manually. The friendly visualized operating interface is equipped with data input and output device.

Fence rolling conveyor belt:

This block making machine uses rolling conveyor belt, featuring with accurate movement, smooth drive, stable performance, low noise, low failure rate, long service life, etc. The added fence and continuously improved safety concept provide the greatest possible safety protection for operators.

Fast mould changing:

Through this system, the machine sets a series of mould coefficient criterion. This system has functions of rapid mechanical locking, rapid tamper head changing device and electronic regulated height of feeding device, ensuring that various molds can be replaced at fastest speed.

Adjustable vibration table:

The height of vibration table can be adjusted to meet the requirement of producing diversified products. The standard equipment can manufacture products with a height of 50-500mm. We can also produce products with special height using special mould following customers' demands.

Accurate feeding:

The feeder is composed of silo, guide board table, feeding car and lever shaft. The height of the anti-twist guide board table can be adjusted and the slide rail can position and move precisely. The lever shaft and ambilateral feeding car of rod drive are driven by hydraulic pressure, and the connecting rod is adjustable, ensuring the feeding car of horizontal moving.

Auxiliary equipment

1. Cement silo

2. Four-silo aggregate batching plant

3. Dual-silo pigments batching plant

4. Aggregate mixer

5. Pigments mixer

6. Belt conveyor

7. Full automatic block making machine

8. Forklift truck

9. Loader

10. Material yard

11. Finished products area

12. Four-way block clamp

Product sample drawing

Colored sponge water permeable brick

Colored sponge water permeable brick  Colored paver brick

Colored paver brick  Curbstone

Curbstone

- Residential pavement

- Swimming pool pavement

- Park pavement

Park footstep

Park footstep  Municipal pavement

Municipal pavement  Parking pavement

Parking pavement

Oman

Oman Oman

Oman Mozambiique

Mozambiique Mozambiique

Mozambiique- Ecuador

- Ecuador