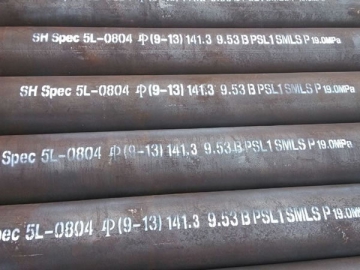

Tube and Pipe for Fluid Transportation

Specifications

Standards: GB/T8163-2008, ASTM A53-98, ASTM A192, ASME S192, JIS G3452-1998, JIS G3454-1998, DIN 1629-1984, etc.

Main Materials: 10#, 20#, Q345

Sizes:

O.D.: 1/2"-24",

Wall thickness: SCH20/40/80/120/160, etc.

Length: max. 12m or customized

Applications

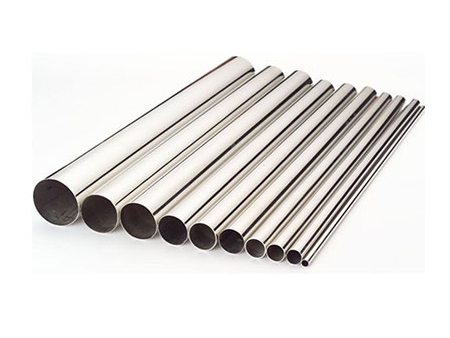

The seamless steel tube is mainly used for transportation of petroleum, natural gas, coal gas, water and some solid materials. This fluid transport tube is mostly applied to large projects. Shenhao offers end beveling services so as to make it convenient for connection of two seamless steel pipes. Moreover, we offer pipe fittings such as flanges, elbows, etc.

Other Applications

Compared with solid steels like round steel, the seamless steel tube for fluid transportation comes with lighter weight under the same bending and torsion strength. It is an economic steel section, and is widely used for making structural parts and machine parts such as oil drill pipe, vehicle transmission shaft, bicycle frame, scaffolds, etc.

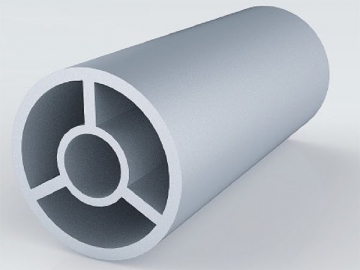

Annular parts made from the steel tubes can improve material utilization ratio, simplify manufacturing process, save materials and reduce machining time. These parts include rolling bearing rings, lifting jack rings, etc.

Mechanical Properties| Standard | Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

| GB/T8163 | 10 | 335~475 | ≥205 | ≥24 |

| 20 | 410~550 | ≥245 | ≥20 | |

| Q345 | 490~665 | ≥325 | ≥21 |

| Standard | Grade | Compositions | |||||||

| C | Si | Mn | P | S | Cr | Ni | Cu | ||

| GB/T8163 | 10 | 0.07~0.14 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 | ≤0.15 | ≤0.25 | ≤0.25 |

| 20 | 0.17~0.24 | 0.17~0.37 | 0.35~0.65 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 | ≤0.25 | |

| Q345 | 0.12~0.20 | 0.20~0.55 | 1.20~1.60 | ≤0.045 | ≤0.045 | / | / | / | |

Production Capacity: 100,000 tons per year

Production Cycle, Packaging, Delivery

The production cycle of the seamless steel tube is about two weeks. This ensures timely delivery based on the order. If there are no special requirements, we provide bundling solution or conduct export packing as required.

Raw Materials

The structural tube is made of the superior steels from Tianjin Iron and Steel Co., Ltd., ensuring reliable quality.

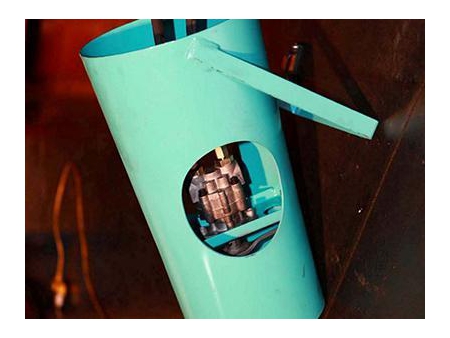

Production Process

Pipe billets inspection—Cutting of qualified billets—Heating—Hot piercing—Tube rolling—Stretch reducing—Cooling on cold bed—Straightening—Cutting—Eddy current testing—Manual surface testing—Packaging—Weighing and Putting in storage