V-640 3-Axis Vertical Machining Center (Linear Guideway) 3 Axis Milling Machine

The three axes move on linear guideways that minimize friction while providing high accuracy of positioning and repeatability. This series machining center is not only suitable for large-scale production line application. It is also ideal for smaller factories and machine shops. Therefore, if you are performing fine processing, this milling machine will be an ideal option. And it only requires a power of 20KVA for operating.

Parameters| Model | V-640 |

| Stroke | |

| X-axis travel (mm) | 600 |

| Y-axis travel (mm) | 400 |

| Z-axis travel (mm) | 450 |

| Distance from spindle nose to table center (mm) | 170-620 |

| Distance between spindle center to column (mm) | 480 |

| Worktable | |

| Worktable area (mm) | 700×420 |

| Maximum weight on table (kg) | 350 |

| T-slot quantity | 3 |

| T-slot size (mm) | 18 |

| Spindle | |

| Standard spindle speed (r.p.m) | 10000 |

| Spindle speed (non-standard) (rpm) | 12000-15000 |

| Spindle horsepower (KW) | 7.5(5.5) |

| Spindle taper | BT-40 |

| Feed | |

| Triaxial rapid feed (mm/min) | 48000 |

| Triaxial cutting feed (mm/min) | 1-10000 |

| Others | |

| Three-axis motor power (KW) | 1.5/1.5/3 |

| Positioning accuracy (mm) | ±0.005/300 |

| Repeatability (mm) | ±0.003/300 |

| Control system | MISUBISHI: M80A/M80B, FANUC:Oi-MF, SINUMERIK 828D |

| Coolant tank (Pump) (HP) | 1/2 |

| Power requirement (KVA) | 20 |

| Air pressure (bar) | 6-7 |

| Machine weight (kg) | 3700 |

| Machine dimension (mm) | 1850×2400×2600 |

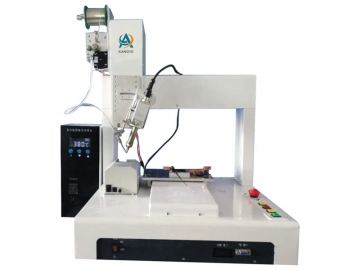

Control system and motor

Control system and motor Mechanical spindle, direct drive

Mechanical spindle, direct drive  Turntable tool storage, holding 24 tools.

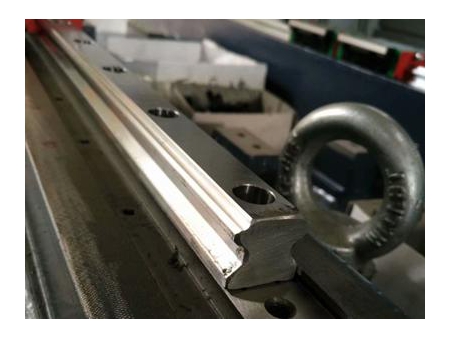

Turntable tool storage, holding 24 tools. Linear guideway runs stably and has high machining precision

Linear guideway runs stably and has high machining precision

Related products

Send Message

Most Recent

More

Other Products

Videos