Medium Speed Wire EDM Machine

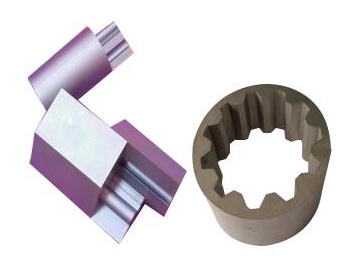

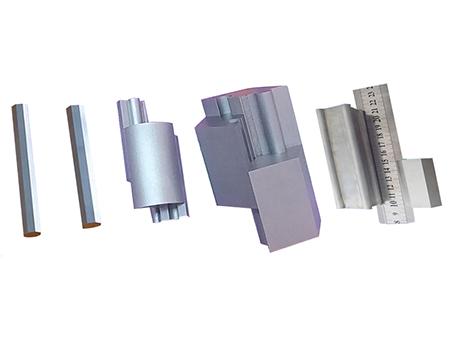

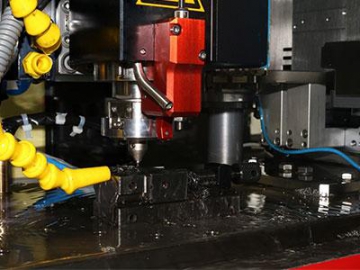

The medium speed wire EDM machine comes with a molybdenum wire. Compared to the high speed wire EDM machine, the medium speed wire EDM machine has a higher machining precision and a faster machining speed, so it is more suitable for cutting high-precision and super-hard materials such as electrodes of a EDM machine, stamping dies, etc.

There are two types of medium speed wire EDM machine. One is controlled by stepper motor and the other is controlled by a servo motor.

The medium speed wire EDM machine with a stepper motor adopts the five-phase stepper motor with ten poles. The pulse from the CNC system (0.001mm) needs to pass through the reduction gear box.

The precision of the medium speed wire EDM machine with an AC servo motor is decided by the rotary encoder at the end of the motor shaft. The pulse equivalent of the AC servo motor is 360°/131072=9.89 seconds, which is 1/655 of the pulse equivalent of the stepper motor. Because the AC servo motor does not have a gear set, there is no gap error and the precision can be higher and the speed can be faster.

The medium speed wire of the medium speed wire EDM machine with a stepper motor is controlled by an open loop control system. If the starting frequency is too high or the machine is overloaded, losing steps or rotor locking will be more likely to occur.

The drive system of the medium speed wire EDM machine with an AC servo motor is a closed loop control system. The driver can directly sample the signal feedback from the motor encoder and form a position loop and a speed loop in the drive, so the stepper motor will not lose steps or overshoot, which makes the control system more stable.

Customers can choose to use stepper motors or servo motors. If the medium speed wire EDM machine has an AC servo motor, the medium speed wire EDM machine can set zero position and realize pitch error compensation of a closed loop control. Since the positioning and machining errors caused by mechanical components such as the transmission gear and the screw can be eliminated, the processing precision of the medium speed wire EDM machine with an AC servo motor is extremely high.

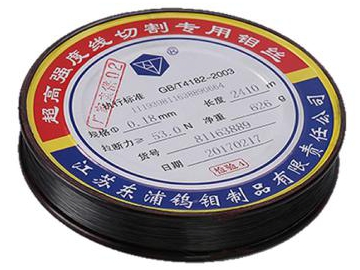

The medium speed wire EDM machine adopts 0.1-0.2mm molybdenum wire as electrode wire. The molybdenum wire has many advantages such as high tensile strength, good abrasion resistance, long service life and high utilization rate.

The medium speed wire EDM machine has a T-shape body, C-shape wire frame, a high-precision linear guideway, a high-precision ball screw and an AC servo motor. The ball screw connects with the motor directly, so the transmission error can be reduced and the medium speed wire EDM machine can run more stable with a higher machining accuracy.

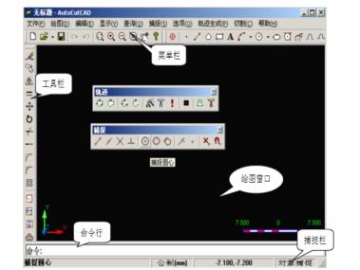

The user interface of the medium speed wire EDM machine and the high speed wire EDM machine is universal. Customers can choose to use HL, HF, X8, Autocut, Windows 7 or the other higher version operating systems. With AutoCAD, the system is a CAD/CAM integration system. The medium speed wire EDM machine can be programmed automatically, preview the processing and display real-time processing.

| Parameter model | Unit | CW-450AC | CW-540AC | CW-650AC | CW-860AC |

| Travel axis X、Y、Z | mm | 450*350*300 | 500*400*300 | 600*500*300 | 800*600*300 |

| Work table size(L*W) | mm | 800*550 | 920*620 | 1020*720 | 1200*850 |

| Machine dimension(W*D*H) | mm | 1520*1350*2100 | 1650*1450*2100 | 1720*1520*2100 | 1920*1680*2100 |

| Machine weight | kgs | 2200 | 2650 | 3200 | 4500 |

| Positioning accuracy | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| Precision accuracy | mm | ±0.003 | ±0.003 | ±0.003 | ±0.003 |

| Max workpiece weight | kgs | 800 | 1000 | 1500 | 2500 |

| Max. taper angle | °/mm | ±6°/80 | ±6°/80 | ±6°/80 | ±6°/80 |

| Max working current | A | 10 | 10 | 10 | 10 |

| Max.cutting speed | mm²/min | 300 | 300 | 300 | 300 |

| Best surface finish | (Ra)μm | 0.6 | 0.6 | 0.6 | 0.6 |

| Drive method | / | AC Servo motor | AC Servo motor | AC Servo motor | AC Servo motor |

| Cabinet model | TP-X8 |

| Power input specification | 220V/380V,50-60Hz |

| PC | Multitasking operating system |

| Display | 17'LED |

| Language | Chinese, English |

| Graphic format | DXF, DAT, DWG |

| File transfer mode | External USB device/LAN |

| Pulse mode | Pulse parameters CPU control power interval adjustable |

| Unit | Metric system/imperial system |

| Cabinet dimensions | 680*580*1800 |

| Total weight (kg) | 80 |

| Parameter model | Unit | CW-450AM | CW-540AM | CW-650AM | CW-860AM |

| Travel Axis X、Y、Z | mm | 450*350*400 | 550*450*400 | 650*500*400 | 800*600*400 |

| Work table size(L*W) | mm | 740*500 | 840*600 | 1020*680 | 1120*780 |

| Machine dimension(W*D*H) | mm | 1520*1350*1900 | 1650*1450*1900 | 1720*1520*1900 | 1860*1650*1900 |

| Machine weight | kgs | 2200 | 2500 | 3100 | 4350 |

| Positioning accuracy | mm | 0.005 | 0.005 | 0.005 | 0.005 |

| Precision accuracy | mm | ±0.004 | ±0.004 | ±0.004 | ±0.004 |

| Max workpiece weight | kgs | 800 | 1000 | 1600 | 2000 |

| Max. taper angle | °/mm | ±6°/80 | ±6°/80 | ±6°/80 | ±6°/80 |

| Max working current | A | 10 | 10 | 10 | 10 |

| Max. cutting speed | mm²/min | 280 | 280 | 280 | 280 |

| Best surface finish | (Ra)μm | 0.8 | 0.8 | 0.8 | 0.8 |

| Drive method | / | Step servo motor | Step servo motor | Step servo motor | Step servo motor |

| Cabinet model | TP-X8 |

| Power input specification | 220V/380V, 50-60Hz |

| PC | Multitasking operating system |

| Display | 17'LED |

| Language | Chinese, English |

| Graphic format | DXF, DAT, DWG |

| File Transfer mode | External USB device/LAN |

| Pulse mode | Pulse parameters CPU control power interval adjustable |

| Unit | Metric system/imperial system |

| Cabinet dimensions | 680*580*1800 |

| Total weight (kg) | 80 |