Annealing Oven

Description of production

The THD01 annealing oven for aluminum tube is associated equipment installed in aluminum tube machine lines.

After the aluminum slug is formed into a tube by cold extrusion, it loses flexibility because of the stress produced by the change of the structure of the metal molecules. Therefore, in order to eliminate this stress and make the tubes body meet the requirements, the de-stressed annealing treatment for tube billet must be performed. The annealed aluminum tube becomes very soft and the mold discharging agent on the surface of the tube evaporates to ensure the adhesion of the inner-coating and under-coating.

This model of annealing oven uses the heating form of gas and hot air circulation, which are clean and energy saving. The conveyor chain places the tube billets one by one into the "C"type ship, and enters the annealing oven in turn through the annealing oven trough. The tube billet followed the "C" type ship to circulate in the chamber of oven, and the annealing was completed after 3 to 5 minutes of high temperature in the annealing oven. Then the tube billet is poured out at the outlet after annealing, which is sent to the cooling zone and sent to the next process by the conveyor chain. The outlet link can be connected with the conveying equipment of other equipment into the next process.

Main technical parameter| suitable diameter of tube | 11mm-25mm25mm-38mm |

| production rate | 60 tubes/minute |

| motor power | 0.75KW |

| dimension | 4832*1300*3040mm |

| whole machine weight | 1800KG |

| operating temperature | 200-500 |

| annealing time | 150s |

| heating capacity | 4KW*8 |

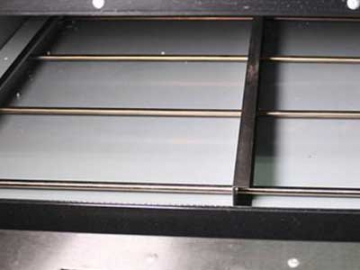

| delivery hopper | "C" type ship |

- All electric heating elements in the oven adopt stainless steel thermal resistance, which can heat evenly and easy to control. The heating element is easy to assemble, disassemble, and replace.

- The THD01 annealing oven adopts the design which can control temperature automatically. The FUJI temperature controller ensures temperature within the plus or minus 2 of the set temperature.

- The feed conveying chain adopts continuously variable regulation, which can make the equipment synchronized with the production speed of the front-end equipment.

- The suspended structure of the chamber of oven facilitates maintenance and makes the operation of the conveyor ship more balanced. It reduces the phenomenon of cans being dropped and broken, thus improving the qualification rate of the product.

- Equipped with a separate driving motor, this machine can either run synchronously with the front and rear equipment or work separately.

Inlet

Inlet Outlet

Outlet Oven

Oven Operation panel

Operation panel