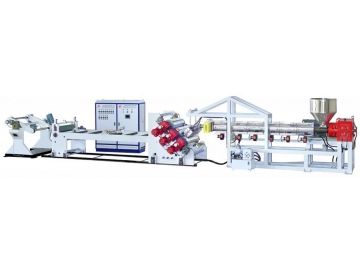

Plastic Sheet, Volumetric Inclined 3-Rolled Sheet Extrusion Line

Application

The SLSE series volumetric inclined 3-rolled sheet extrusion line was developed by our engineers to handle materials such as PP, PE, PS, HIPS, and other plastic sheet products. The volumetric sheet extrusion unit can be outfitted with a measuring pump, PLC control system, 3-roller independent control system, 3-roller tank, and other high quality accessories from Siemens, SMC, JCTIMES, and other well-known brands. The equipment provides a high degree of automation, quick response times, and stable operation. If you have a high demand for machine performance, then this is the equipment for you.

The sheets mass-produced using this sheet extrusion machine can be used in cup making machines, thermoplastic forming machines, flip molding machines, multi-station forming machines, and other plastic thermoforming equipment. Those machines are used in the production of disposable plastic cups, beverage cups, ice cream cups, jelly cups, and other packaging products.

Production technique

This volumetric inclined 3-rolled sheet extrusion line is made up of an extrusion machine, 3-rolled calender, traction winder and electrical control cabinet.

The process includes:

Feeding → Heating → Extrusion → Calendering → Cooling → Winding

| Used material | Sheet effective width | Sheet thickness | Length-diameter ratio of the screw | Main motor power | Maximum extrusion capacity | Total power | Size (L*W*H) |

| PP,PS,HIPS,PE | ≤750mm | 0.2-2.0mm | 33:1 | 45kw | 150kg/h | 90kw | 12*2.0*3.5m |

| Used material | Sheet effective width | Sheet thickness | Length-diameter ratio of the screw | Main motor power | Maximum extrusion capacity | Total power | Size (L*W*H) |

| PP,PS,HIPS,PE | ≤750mm | 0.2-2.0mm | 33:1 | 55kw | 200kg/h | 120kw | 13*2.1*3.5m |

| Used material | Sheet effective width | Sheet thickness | Length-diameter ratio of the screw | Main motor power | Maximum extrusion capacity | Total power | Size (L*W*H) |

| PP,PS,HIPS,PE | ≤750mm | 0.2-2.0mm | 33:1 | 75kw | 250kg/h | 150kw | 14*2.1*3.5m |

| Used material | Sheet effective width | Sheet thickness | Length-diameter ratio of the screw | Main motor power | Maximum extrusion capacity | Total power | Size (L*W*H) |

| PP,PS,HIPS,PE | ≤750mm | 0.2-2.0mm | 33:1 | 90kw | 350kg/h | 180kw | 15*2.2*4.0m |

ELITE Plastics is manufacturing plastic forming and sheet extrusion equipment, such as sheet extrusion line for various plastic materials like PE, PPT, PS, PET, etc. and offers the custom thermoplastic machines and thermoforming equipment and other plastic thermoforming machines. With almost 20 years experiences of manufacturing plastic machines, ELITE Plastics can provide any client good plastic thermoplastic and extrusion machines.

Index

plastic extruder, plastic extrusion line, polyethylene extruder, polypropylene extruder, polystyrene sheet extruder, HIPS extruder