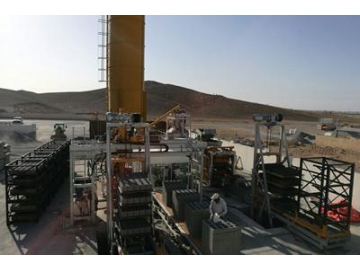

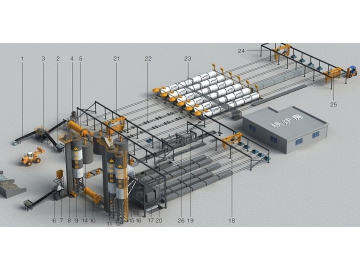

Fully Automatic Block Production Line With Curing Rack

Description

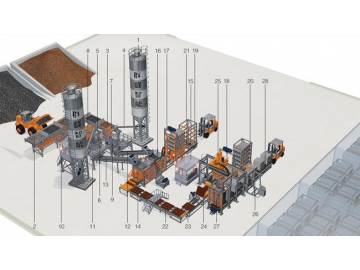

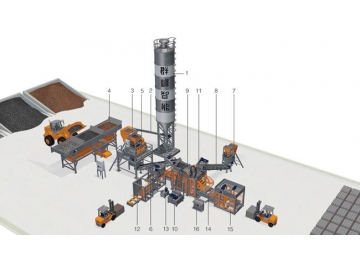

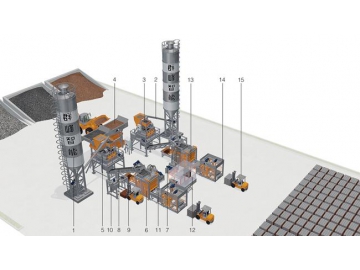

The this is a fully automatic hollow block production line with curing rack, this hollow block production line consists of automatic concrete scale and concrete batching plant , automatic the cement and other material before concrete mixing, automatic concrete hollow blocks molding section, and the lifting system , wet and cured blocks conveying, automatic stacking system, pallet returning , and cured block packing system. only 5 staff can operate this block production line, can make concrete block, building hollow blocks, concrete brick, paving bricks etc.

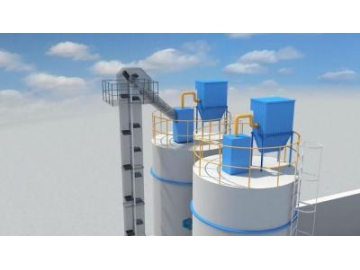

- 1. Cement Silo

- 2. Batching Machine

- 3. Screw Conveyor

- 4. Cement Scale

- 5. Coarse Material Mixer

- 6. Pigment Mixer

- 7. Mixed Material Transit Hopper

- 8. Mixed Pigment Transit Hopper

- 9. Mixing Platform

- 10.Belt Conveyor for Coarse Material

- 11.Belt Conveyor for Pigment

- 12.Block Making Machine

- 13.Computer Control System

- 14.Auto.Color Feeding System

- 15.Elevator

- 16.Lowerator

- 17.Automatic Block Loader

- 18.Automatic Block Unloader

- 19.Cured Block Conveyor

- 20.Pallet-Stop Machine (Compound)

- 21.Ladder Pallet Turnover

- 22.Cuber Conveyor

- 23.Cuber

- 24.Tray Bin

- 25.Loader

- 26.Forklift

- QFK-1 390x140x190mm concrete hollow block

- QFK-2 390x140x190mm concrete hollow block

- QFK-3 390x140x190mm concrete hollow block

- QFK-4 390x140x190mm concrete hollow block

- QFK-5 390x140x190mm hollow concrete block

- QFK-6 190x190x190mm hollow concrete block

| Fully Automatic Block Production Line with Curing Rack (Without Packing System) | |||

| Item | No. | Name | Model |

| Automatic Batching & Mixing System | 1 | Cement Silo (For Coarse material) | 100T |

| 2 | Cement Silo (For Pigment) | 45T | |

| 3 | Automatic Batching Machine | PL1200-III | |

| 4 | Screw Conveyor | φ219X5m | |

| 5 | Cement Scale (Including water scale) | Z3500 | |

| 6 | Concrete Mixer | JS750 | |

| 7 | Pigment Mixer (With Loading System and Water Pump) | JQM500 | |

| 8 | Mixed Material Transit Hopper | ||

| 9 | Mixed Pigment Transit Hopper | ||

| Forming System | 10 | Mixing Platform | |

| 11 | Belt Conveyor for Pigment | 0.5×8.4m | |

| 12 | Belt Conveyor for Raw Material | 0.8×10.3m | |

| 13 | Transit Conveyor | 0.8×3.5m | |

| 14 | Block Making Machine (Including Hydraulic System) | ||

| 15 | Mold Change Platform | ||

| 16 | Auto. Color Feeding System | ||

| Transferring System | 17 | Wet Block Conveyor (Chain type L=11.6m) | |

| 18 | Pedestrian Bridge | ||

| 19 | Block Brushing Machine | ||

| 20 | Elevator (9 Layers) | ||

| 21 | Lowerator (9 Layers) | ||

| 22 | Program-controlled Finger Cart | ||

| 23 | Cured Block Conveyor (Walking mode L=17.37m) | ||

| 24 | Automatic Cuber | ||

| 25 | Pallets Brushing Machine | ||

| 26 | Pallets Turnover | ||

| 27 | Horizontal Pallets Conveyor (Walking mode L=10m) | ||

| 28 | Pallets Oil-painting Machine | ||

| 29 | Pallets Feeder | ||

| 30 | Tray Bin | ||

| 31 | Tray Bin Chain Type Conveyor(20m) | ||

| Electrical Control System | 32 | Central Control Room | |

| 33 | Control System for Concrete and Pigment Mixer (with Automatic Wet Testing System) | ||

| 34 | Control System for Main Machine Forming System (with Industrial Computer) | ||

| 35 | Control System For Finger Cart | ||

| 36 | Control System for Cuber | ||

| Note: | |||

| 1. Curing Room, Steel Track, Workshop and other supporting equipment should be supplied by the Buyer. 2. All kinds of mold can be made per the customer's drawings. | |||

| Fully Automatic Block Production Line with Curing Rack (Including Packing System) | |||

| System | No. | Name | Model |

| Automatic Batching & Mixing System | 1 | Cement Silo (For Coarse material) | 100T |

| 2 | Cement Silo (For Pigment) | 45T | |

| 3 | Automatic Batching Machine | φ219×5m | |

| 4 | Screw Conveyor | Z3500 | |

| 5 | Cement Scale (Including water scale) | PL1200-III | |

| 6 | Concrete Mixer | JS750 | |

| 7 | Pigment Mixer (With Loading System and Water Pump) | JQM500 | |

| 8 | Mixed Material Transit Hopper | -- | |

| 9 | Mixed Pigment Transit Hopper | -- | |

| Forming System | 10 | Mixing Platform | -- |

| 11 | Belt Conveyor for Pigment | 0.5×8.4m | |

| 12 | Belt Conveyor for Raw Material | 0.8×10.3m | |

| 13 | Transit Conveyor | 0.8×3.5m | |

| 14 | Block Making Machine | ||

| 15 | Mould Change Platform | ||

| 16 | Auto. Color Feeding System | ||

| Transferring System | 17 | Wet Block Conveyor (Chain type L=11.6m) | |

| 18 | Pedestrian Bridge | ||

| 19 | Block Brushing Machine | ||

| 20 | Elevator (9 Layers) | ||

| 21 | Lowerator (9 Layers) | ||

| 22 | Program-controlled Finger Cart | ||

| 23 | Cured Block Conveyor (Walking mode L=17.37m) | ||

| 24 | Automatic Cuber | ||

| 25 | Pallets Brushing Machine | ||

| 26 | Pallets Turnover | ||

| 27 | Horizontal Pallets Conveyor (Walking mode L=10m) | ||

| 28 | Pallets Oil-painting Machine | ||

| 29 | Pallets Feeder | ||

| 30 | Tray Bin | ||

| Electrical Control System | 31 | Central Control Room | |

| 32 | Control System for Concrete and Pigment Mixer (with Automatic Wet Testing System) | ||

| 33 | Control System for Main Machine Forming System (with Industrial Computer) | ||

| 34 | Control System For Finger Cart | ||

| 35 | Control System for Cuber | ||

| Automatic Packing System | 36 | Horizontal Packing Machine | |

| 37 | Sword Type Packing Machine | ||

| 38 | Film Wrapping Machine | ||

| 39 | Conveyor | ||

| Note: | |||

| 1. Curing Room, Steel Track, Workshop and other supporting equipment should be supplied by the Buyer. 2. All kinds of mold can be made per the customer's drawings. | |||

Qunfeng is a China-based manufacturer of fully automatic hollow blocks and concrete bricks block production line with curing rack. We offer a wide range of concrete building material machines and cement machines like concrete hollow block making machines, concrete brick making machine, hollow block production line including concrete batch plant and block forming unit, cutting section ,conveying belt machines , stocking and pullet retuning system, also make road and street cleaning machine , building construction material recycling machines etc.

Index

block making machine, brick machine, concrete masonry unit, cinder block