MR6-300Y (for Juice)

Liquid packing machine

MR6-300Y--Juice Packaging Machine

Product Name: Automatic packing machine

Model: MR6-300Y

Categories: Pouch, bag fill and seal packing machine/MR6-300Y Liquid Packing Machine

Parts: ,

Main Features of Pre-Made Pouch Filling and Sealing Machine

1, Full automatic 6-station intermittent rotary performed bags dispensing,opening and closing machine combines

2, Safety guard protected for high speed and consistent production.

3, Heavy duty components and parts are selected for machine durability.

4, Hygienic construction and easy cleaning. Operator friendly design touch-screen control system.

5, Versatile in design,easy to link up with other down stream packaging equipment,such as liquid filler

powder filler, multiheads weigher,metal detector,check weighter,case sealer etc.

6, Innovative and practical solution at reasonable costs.

7, Dust control and extractor system on special request.

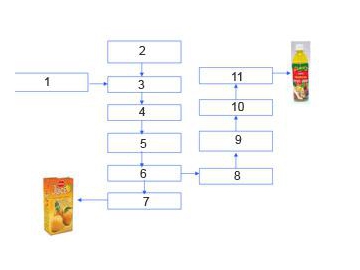

Typical Flow Chart of Pre-Made Pouch Filling and Sealing Machine

1. Bags dispensing

2. Hot Foil Coding

3. Bags Opening

4. Dosing

5. Heating sealing

6. Discharge

| Model | MR6-300 |

| No. of working station | Eix |

| Bags size | W:80-200 L:no limit |

| Filling Volume | 5-1500g(depending on type pf product) |

| Packaging Materials | Zipper bag, stand-up bag, spout bags etc |

| Capacity | 60bags/min(depending on type of product and packaging material used) |

| Total power consumption | 5Kw |

| Weight accuracy | R≤±1 |

| Type | Filling Machine |

| Condition | New |

| Application | Beverage, Food |

| Packaging Type | Bags, Film, Foil, Pouch, Stand-up Pouch, bag |

| Packaging Material | Plastic |

| Automatic Grade | Automatic |

| Driven Type | Mechanical |

| Voltage | 380V/220V |

| Power | 3.5kw |

| Place of Origin | Zhejiang, China (Mainland) |

| Brand Name | Echo |

| Model Number | MR6-300 packaging machine |

| Certification | CE, ISO9100 |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Packaging machine Material | Stainless steel |

| Automatic packaging machinery | Rotary packaging machinery |

| Rotary packaging machinery | Powder packaging machine |

| Packaging machinery for food | Powder filling and sealing machine |

| Pemade packaging machine | Auto rotary packaging machine |

| Filling and sealing packaing machinery | Food Auto packaging machinery Echo |

| Food Rotary packing machine | Automatic Food Packaging Machinery |

| Coffee Powder Rotary Packing Machine | Fill-Seal Packing Machine for Coffee Powder |

| Rotary packing machine | Zipper and stand-up pouch packing machine |

| Packaging Details | Soild pouch packing machine W ooden case |

| Delivery Detail | 30 days |

1. Liquid Pump

The machine can send the packed finished bag to after-package detecting device or packing platform.

Features of Liquid Pump

Famous brands for electrical components, guaranteeing high quality and stable running.

Control system by PLC for high accuracy and adjusting range.

Compatible with various filling systems.

Suitable to package liquid materials, such as shampoo, facial cream,oil, sauce,jam, etc.

| Item | Small type | Middle type | Large type |

| Filling range | 30-250ml | 50-1000ml | 100-5000ml |

| Capacity | 10-30bags/min | 8-25bags/min | 6-20bags/min |

| Accuracy | ±1/% | ±1/% | ±1/% |

| Total powder | 220V 50HZ | 220V 50HZ | 220V 50HZ |

| Dimension | L1000*W560*H1550mm | L1280*W660*H1650mm | L1000*W560*H1550mm |

| Weight | 55kg | 75kg | 80kg |

2. Finished Products Conveyor

Features of Finished Products Conveyor

The machine can send the packed finished bag to after-package detecting device or packing platform.

| Lifting height | 600-800MM |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30m/minute |

| Dimension | 2110 ×340×500mm |

| Voltage | 220V/45W |