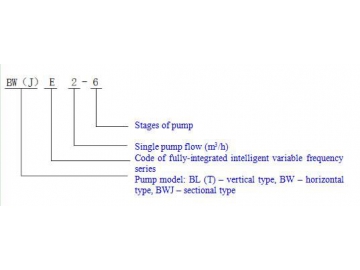

BW(J)E BL(T)E Fully-integrated Intelligent Variable Frequency Pump

BW(J)E and BL(T)E series fully integrated intelligent variable frequency pump is a new generation of pressurized water supply equipment newly developed by us which highly integrates variable frequency controller, water pump and pressure tank; with handsome appearance, the pump has reached the international advanced level; provided with artificial intelligence, it can adjust automatically to meet the user’s requirement for constant pressure and variable frequency water supply, so as to keep constant the pressure of water supply network and maintain the whole system at the optimal energy-efficient state.

- Domestic water supply: Roof pressurization for high-rise building, apartment, and villa, etc.

- Public places: School, restaurant, station, hospital, and gymnasium, etc.

- Commercial buildings: Hotel, office building, and department store, etc.

- Irrigation: Farm, orchard, and park, etc.

- Industry: Manufacturing, food industry, industrial water supply and other places requiring constant pressure water supply.

- Operating voltage AC220V±10%, 50HZ, with interphase unbalance less than 2%.

- Ambient temperature -5°C ~ 40°C;

- The altitude at the installation site is no more than 1000m;

- Ambient humidity 10-90%RH (non-condensing);

- There is no medium with explosive risk in the ambient air, and there is no gas or conducting dust which is enough to corrode metal and damage insulation in ambient media. The product is designed to operate in the environment with the pollution class II.

- When water is used, the system is kept at constant pressure by variable control; when water is not used, the system pressure is automatically maintained with the pump shut down.

- The operating pressure fluctuation range of variable frequency pump is no more than 0.01MPa.

- The pump shuts down if it idles without water.

- The pump has the function of detecting such faults as disconnection, overcurrent, overload, and earthing.

- Frequency converter: With the protection class of IP65, it’s safe and reliable.

- High integration: Water pump and frequency converter are integrated with small volume, easy to install and space saving.

- Full-automatic control: The pump can automatically adjust its operating state according to the user’s pipe network pressure to reach the optimal operating state and make the system more energy-saving. When no water is used, it automatically maintains the pressure and goes to sleep, with obvious energy-saving effect. When the pump breaks down, it automatically performs real-time tracking, judgment and handling.

- Convenient and simple operation: Man-machine interaction can be realized directly through buttons and display at the frequency converter, and the user can make pressure-related settings according to the actual operating conditions, and obtain relevant information; in case of any abnormality, the user can obtain information about the abnormality.

- Constant-power operation: When the controller reaches the limit power, it adjusts according to actual operating conditions; with water supply for the user guaranteed wherever possible, the output power is unchanged to realize protection of the motor.

The automatic identification module senses the system pressure through pressure sensor, compares it with the set pressure, and outputs continuous analog signal to the frequency converter, and then the variable frequency controller changes the operating frequency of motor according to the change of analog signal so as to reach the requirement for constant water supply. When the user’s water consumption is large, the pump automatically increases the rotating speed and power to meet the requirement for constant water supply. When no water is used, the pump automatically sleeps after the system reaches the set pressure, and only when the water pressure drops to 80% because the user uses a small amount of water or the pipeline leaks, the variable frequency controller sends signal to order the motor to operate to compensate the pressure to the set pressure, so as to realize energy saving to the greatest extent.

| No. | Model | Input voltage | Constant pressure Setting range kg/cm² | Constant pressure set at delivery (rated pressure) kg/cm2 | Inlet diameter | Outlet diameter | Single pump power kW | Max. lift (zero flow) m | Rated flow m3/h | Volume of pressure tank L |

| A03 | BW(J)E2-6 | 1ΦAC220V | 0.5-4 | 4 | G1 | G1 | 0.75 | 56 | 2 | 3 |

| A05 | BW(J)E4-4 | 1ΦAC220V | 0.5-3 | 3 | G1 | G1 | 0.75 | 38 | 4 | 3 |

| A06 | BWJE4-5 | 1ΦAC220V | 0.5-3.5 | 3.5 | G1 | G1 | 1.1 | 47 | 4 | 3 |

| A07 | BWJE4-6 | 1ΦAC220V | 0.5-5 | 3 | G1 | G1 | 1.1 | 57 | 4 | 3 |

| A08 | BWE8-2 | 1ΦAC220V | 0.5-1.5 | 2 | G2 | G2 | 0.75 | 22 | 8 | 5 |

| A09 | BWE8-3 | 1ΦAC220V | 0.5-2 | 2 | G2 | G2 | 1.1 | 32 | 8 | 5 |

| A12 | BWJE8-2 | 1ΦAC220V | 0.5-1.5 | 1.5 | G1 | G1 | 0.75 | 22 | 8 | 5 |

| A13 | BWJE8-3 | 1ΦAC220V | 0.5-2 | 2 | G1 | G1 | 1.1 | 32 | 8 | 5 |

| B03 | BL(T)E2-6 | 1ΦAC220V | 0.5-4 | 4 | G1 | G1 | 0.75 | 58 | 2 | 3 |

| B04 | BL(T)E2-7 | 1ΦAC220V | 0.5-5 | 5 | G1 | G1 | 0.75 | 68 | 2 | 3 |

| B05 | BL(T)E2-9 | 1ΦAC220V | 0.5-6 | 6 | G1 | G1 | 1.1 | 87 | 2 | 5 |

| B06 | BL(T)E2-11 | 1ΦAC220V | 0.5-8 | 8 | G1 | G1 | 1.1 | 106 | 2 | 5 |

| B09 | BL(T)E4-4 | 1ΦAC220V | 0.5-3 | 3.5 | G1 | G1 | 1.1 | 50 | 4 | 3 |

| B09 | BL(T)E4-5 | 1ΦAC220V | 0.5-3.5 | 3.5 | G1 | G1 | 1.1 | 50 | 4 | 3 |

| B10 | BL(T)E4-6 | 1ΦAC220V | 0.5-4 | 4 | G1 | G1 | 1.1 | 58 | 4 | 3 |

| B14 | BL(T)E8-2 | 1ΦAC220V | 0.5-1.5 | 1.5 | DN40 | DN40 | 0.75 | 22 | 8 | 5 |

| B15 | BL(T)E8-3 | 1ΦAC220V | 0.5-2 | 2 | DN40 | DN40 | 1.1 | 32 | 8 | 5 |

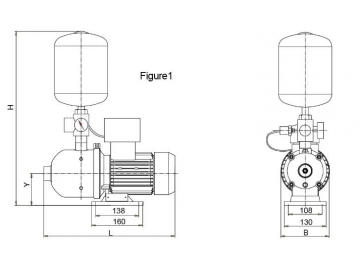

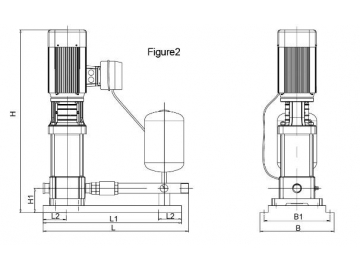

| No. | Model | L | L1 | B | H | H1 | Schematic diagram |

| A03 | BW(J)E2-6 | 402(445) | 165(151) | 220 | 630 | 140 | 1 |

| A05 | BW(J)E4-4 | 419(445) | 168(151) | 220 | 630 | 140 | 1 |

| A06 | BWJE4-5 | 472 | 178 | 220 | 630 | 140 | 1 |

| A07 | BWJE4-6 | 499 | 232 | 220 | 630 | 140 | 1 |

| A08 | BWE8-2 | 539 | 272 | 227 | 680 | 148 | 1 |

| A09 | BWE8-3 | 539 | 272 | 227 | 680 | 148 | 1 |

| A12 | BWJE8-2 | 376 | 111 | 227 | 680 | 148 | 1 |

| A13 | BWJE8-3 | 406 | 141 | 227 | 680 | 148 | 1 |

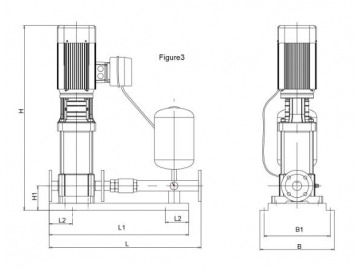

| No. | Model | L | L1 | L2 | B | B1 | H1 | H1 | Schematic diagram |

| B03 | BL(T)E2-6 | 610 | 550 | 100 | 320 | 280 | 80 | 587 | 2 |

| B04 | BL(T)E2-7 | 610 | 550 | 100 | 320 | 280 | 80 | 605 | 2 |

| B05 | BL(T)E2-9 | 610 | 550 | 100 | 320 | 280 | 80 | 641 | 2 |

| B06 | BL(T)E2-11 | 610 | 550 | 100 | 320 | 280 | 80 | 644 | 2 |

| B08 | BL(T)E4-4 | 610 | 550 | 100 | 320 | 280 | 80 | 587 | 2 |

| B09 | BL(T)E4-5 | 610 | 550 | 100 | 320 | 280 | 80 | 587 | 2 |

| B10 | BL(T)E4-6 | 610 | 550 | 100 | 320 | 280 | 80 | 641 | 2 |

| No. | Model | L | L1 | L2 | B | B1 | H1 | H | Schematic diagram |

| B14 | BL(T)E8-2 | 750 | 700 | 100 | 360 | 320 | 120 | 652 | 3 |

| B15 | BL(T)E8-3 | 750 | 700 | 100 | 360 | 320 | 120 | 652 | 3 |

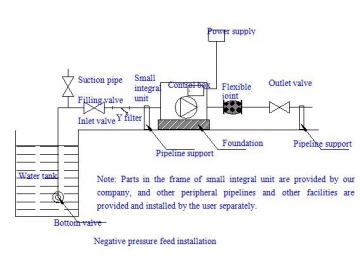

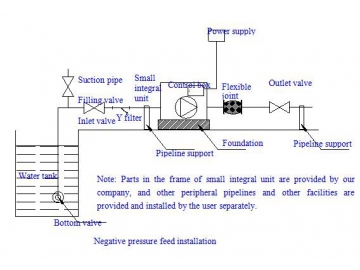

Schematic installation diagram

- The pump should be installed in an indoor place free from water drop, metal dust, oily dust, corrosive or inflammable gas or liquid, and disturb of electromagnetic signals. When it’s installed outdoors, it should be provided with sheltering device.

- The ground for installation of variable frequency pump must be firm without sinking or cracking.

- At the installation of equipment, inlet positive pressure installation should be adopted, avoiding negative pressure suction installation wherever possible. If negative pressure installation must be adopted, please select a bottom valve with good quality, and carry out periodical maintenance.

- The inlet pipe and outlet pipe of variable frequency pump must be larger than the pipe diameter of the pump in diameter.

- Please note whether the power supply provided meets the requirement for incoming power supply of variable frequency pump.

- At installation, the user should provide inlet and outlet valves for variable frequency pump, and flexible joints for connection, which facilitate maintenance and prevent noise from transmitting through pipeline.

- When inlet positive pressure installation is adopted, please open the vent valve of pump to exhaust air before use, and close it until water comes out. When inlet negative pressure installation is adopted, please fill the suction pipe with water (a filling valve needs to be installed at suction pipe) before use, and start the pump after the pump cavity is filled with water.

Method of Calculating the Maximum Water Consumption

| No. | Name of water supply fittings | Rated flow (L/s) | Equivalent | Nominal diameter of connecting pipe (mm) | Min. operating pressure (MPa) |

| 1 | Sink, mop basin, and bathroom sink Single-valve tap Single-valve tap Mixing tap | 0.15~0.20 0.30~0.40 0.15~0.20(0.14) | 0.75~1.00 1.5~2.00 0.75~1.00(0.70) | 15 20 15 | 0. 050 |

| 2 | Lavatory Single-valve tap Mixing tap | 0.15 0.15 (0.10) | 0.75 0.75(0.50) | 15 15 | 0. 050 |

| 3 | Hand basinInductive tap Mixing tap | 0.10 0.15(0.10) | 0.50 0.75(0.5) | 15 15 | 0. 050 |

| 4 | Bathtub Single-valve tap Mixing tap (with shower converter) | 0.20 0.24(0.20) | 1.00 1.2(1.0) | 15 15 | 0. 050 0. 050~0.0 70 |

| 5 | Shower Mixing valve | 0.15(0.10) | 0.75(0.50) | 15 | 0. 050~0.100 |

| 6 | Closet pan Ball float valve of flush tank Time-lapse self-closing flushing valve | 0.10 1.20 | 0.50 6.00 | 15 25 | 0.020 0.10~0.15 |

| 7 | Urinal Manual or automatic self-closing flushing valve Inlet valve of automatic flush tank | 0.10 0.10 | 0.50 0.50 | 15 15 | 0.0 50 0. 020 |

| 8 | Perforated flushing pipe for urinal trough (per meter) | 0.05 | 0.25 | 15~20 | 0. 015 |

| 9 | Flushing tap of bidet | 0.10(0.07) | 0.50(0.35) | 15 | 0.0 50 |

| 10 | Hospital bedpan flusher | 0.20 | 1.00 | 15 | 0. 050 |

| 11 | Laboratory water tap (gooseneck) Single Double Triple | 0.07 0.15 0.20 | 0.35 0.75 1.00 | 15 15 15 | 0. 020 0. 020 0. 020 |

| 12 | Drinker nozzle | 0.05 | 0.25 | 15 | 0.0 50 |

| 13 | Sprinkler head | 0.40 | 13 | Sprinkler head | 0.40 |

| 14 | Indoor floor flushing tap | 0.20 | 1.00 | 15 | 0. 050 |

| 15 | Domestic washing machine tap | 0.20 | 1.00 | 15 | 0.050 |

- Numerical values in brackets in the table are used for calculating cold water or hot water separately when hot water is available;

- When a bathtub is attached with a shower, or a mixing tap has shower change-over switch, the rated flow and equivalent shall be calculated by water tap but not the shower. However, water pressure shall be calculated by the shower;

- The water pressure required for domestic gas water heater shall be determined according to the product requirements and the operating pressure required for the most unfavorable distribution point of the hot water supply system;

- Automatic spray irrigation for greenbelt shall be designed according to product requirements;

- When special requirements are set for the rated flow and minimum operating pressure of water supply fittings of sanitary ware, the value shall be determined according to product requirements. (How to determine the equivalent when product requirements are set)

- Calculation of maximum water consumption

L = number of single-valve tap * rated flow mixing tap * rated flow ······ number of domestic washing machines * rated flowThe unit of calculated L is (L/S), and it should be multiplied by 3.6 when the unit is converted to T/H. (See Table 1 for rated flow) - Calculation of minimum pressure

The minimum pressure shall be calculated from the water suction level of water pump plus the minimum necessary pressure of the highest sanitary ware used.

Minimum service pressure of water supply equipment (Mpa) ≈1/100*(hg hf) pe

Ha: Actual lift from water suction level to the highest sanitary ware (m)

Hf: Head loss of pipelines and bends (m), which may take 6m-10m.

Pe: Minimum necessary pressure of the highest sanitary ware (see Table 1)

Example: A small hotel, which has four over-ground floors with the height of about 12m (from the water suction level), has 12 rooms in the hotel, and each room is equipped with one closet pan, one hand basin (mixing tap), and one shower (mixing tap); in addition, the hotel has one water tap for washing machine, four indoor floor flushing taps, and four drinker taps. Please calculate the flow and lift of water supply equipment to be used.

Solution: Calculation of maximum water consumption:

Maximum water consumption: 3.6 {12 (1*0.1 1*0.15 1*0.24) 1*0.2 4*0.2 4*0.05} = 6.084 T/H

Minimum pressure:

Minimum pressure ≈1/100* (12 10) 0.07=0.29 Mpa

Ha: The actual lift from water suction level to the highest sanitary ware is 12m.

Hf: Head loss of pipelines and bends take 10m.

Pe: The minimum operating pressure of shower is 0.7 bar.

Note: 1bar≈1kg/cm2=0.1Mpa, 1Mpa is approximately equal to the pump lift of 100m.

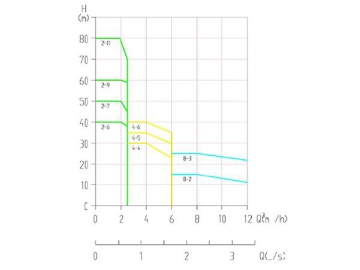

When selecting equipment, the total flow of selected equipment is the maximum water consumption, and the lift is no less than the calculated minimum pressure; please refer to the equipment type spectrum.