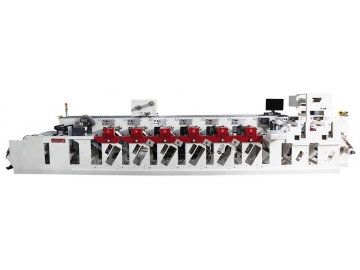

Flexo Printing Press

Roll-to-roll printing machine for coated and uncoated fabric combines outstanding print quality in 4, 6 or 8 colors

Tianye’s flexo printing press is designed to simultaneously print on a single side or both sides of the substrate, with a printing capacity of 80m/min. Operators can set the printing quantity or printing meters. Once the printing parameters are set, the printing press will prompt the start of the printing process.

Applications:

This flexo printing press features a flexible configuration for continuous dual sided printing, label printing, UV glazing, embossing, die-cutting, laminating, gold blocking, slitting, and other printing processes. It can be used to print on woven bags as well as other flexible packaging products and labels.

This flexo printing press features a flexible configuration for continuous dual sided printing, label printing, UV glazing, embossing, die-cutting, laminating, gold blocking, slitting, and other printing processes. It can be used to print on woven bags as well as other flexible packaging products and labels.

Technical specifications

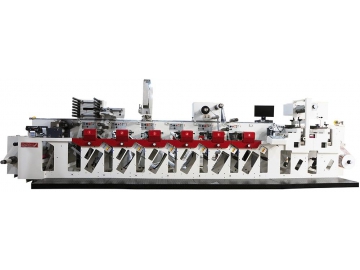

| Model | SBY-4800 | SBY-6800 |

| Printing color | 4 color | 6 color |

| Printing style | Flexo, roll to roll 4 0, 3 1, 2 2 | Flexo, roll to roll 6 0, 5 1, 4 2, 3 3 |

| Max. width of printed material | 800mm | 800mm |

| Max. width of printing | 700mm | 700mm |

| Max. length of repeat printing | 500 - 1300mm | 500 - 1300mm |

| Thickness of plate and tape | 4.0 - 6.0mm | 4.0 - 6.0mm |

| Register precision | ±0.50mm | ±0.50mm |

| Printing capability | 50 - 80m/min | 50 - 80m/min |

| Max. dia. of unwinding | 1200mm | 1200mm |

| Max. dia. of rewinding | 1200mm | 1200mm |

| System installed power | 15kw | 15kw |

| Normal operational power (approx.) | 10kw | 10kw |

| Overall dimension (L×W×H) | 13000×2150×2250mm | 13000×2150×2800mm |

Features

- The integral steel cast machine frame guarantees stable operation of the flexo printing press.

- The main motor applies frequency stepless speed regulating.

- Feeding and rewinding are controlled by a magnetic particle clutch and clutch control.

- The unwinding unit is controlled by an automatic skew detection sensor.

- Ceramic anilox rolls offer a long service life, wear resistance and corrosion resistance, which is advantageous in reducing the number of times the anilox roll needs to be changed, and thus, improves the printing efficiency.

- The printing unit is adjustable by 360°.

- Each printing unit is equipped with a group of infrared drying devices or interchangeable UV drying devices.

- When the machine stops, the ink rolls automatically stop and print out to prevent the ink from drying out.

- The roll feeding, printing, glazing, auto infrared drying, laminating and rewinding processes are all performed in a single pass.

Related products

Send Message

Most Recent

More

Other Products

Videos