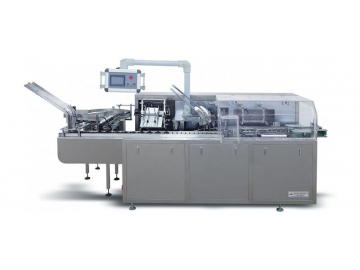

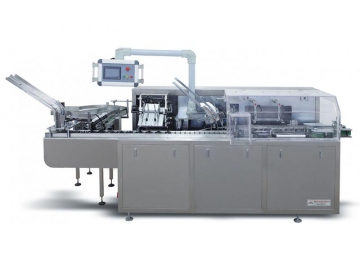

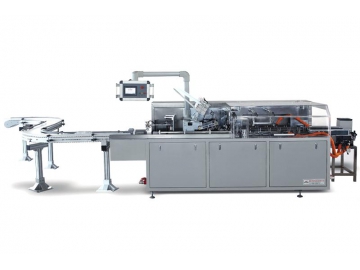

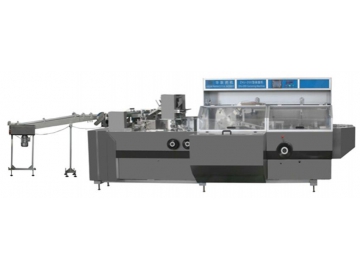

KXZ-200B Packaging Cartoner, Cartoning Machine

Introduction

The KXZ-200B packaging cartoner is designed for packages of L (70-350)mm×W(80-200)mm×H(20-90)mm, special sizes can be customized.

This packaging machine can pack items of different sizes such as various medicine, auto parts, food, cosmetics and some other small utensils. It is also able to pack and seal packages of certain sizes and send them out for shipping.

A PLC unit controls the machine and allows it to run intermittently, which makes the production process highly efficient. The structure is simple and is easy to maintain. This cartoner can be used independently or used in a production line along with blister pack cartoning machines, hot melt glue cartoner sand other devices. It can be applied in a large range of areas and has multiple uses.

Features

- This whole cartoner operates according to the current GMP workshop standards.

- It is controlled by PLC and there is an electro-optical tracking system to monitor every step to shut down the machine and show problems. This can help you eliminate problems in time.

- Packaging will stop when there is no item. There is also an overload protection device for main drive motor making the operation safer and more reliable.

- The machine has an electro-optical tracking system to avoid empty packaging, which saves packaging materials.

- This packaging machine can adopt a flip-up protective cover according to customer requirements, which is good-looking and easy to use.

- The PLC automatic output interface can realize real-time monitoring of the subsequent section of packaging.

- The packaging process is intermittent and there is an overload protection function to make the process safe.

- Packaging will stop when there is no carton and packaging will pause when there are no items to load into the cartons.

- Finished packages are of a good quality and good-looking.

- The base of the whole machine is equipped with a threaded base plate, and the height is adjustable.

Loading units, Materials are automatically to be put into the cartons in order stably.

Carton store is where the cartons are stored (300-500 cartons one time). It can be adjusted to a longer one according to customer's needs. It can save time and make packaging more efficient.

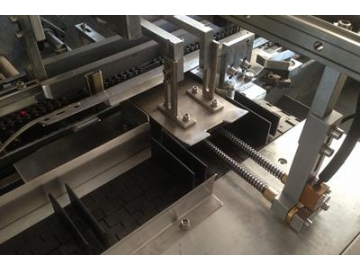

Double suction cup can open the carton precisely and quickly. The suction cup can suck the carton down to the bottom suction cup and then put it to chains. The whole suction structure is controlled by a crank to adjust time distribution as required.

Material pusher unit, It can push the materials firmly and package items stably. If the item is stuck, this cartoner will shut down and soundan alarm.

Flap closing station.

The sealing device cements the outer flaps and lock the material in the carton firmly and good-looking.

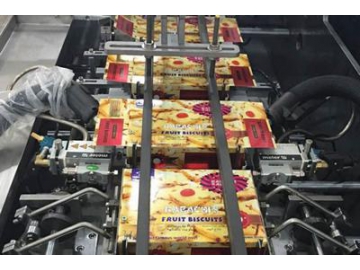

Conveying Unit. It conveys products out steadily.

American hot melt glue machine. The spraying of glue is fast and the glue is stable, strong and non-toxic.

Japanese PLC system is applied and it makes the operation stable and easy. Once any problem happens, our machine will shut down automatically and show the problem in order to solve problems in time.

German SICK infrared protector is able to detect and track the whole system automatically and precisely, making sure this packaging machine runs normally.

| Packing speed | 30-80 cartons/min |

| Size of package | L(70-350)mm×W(80-200)mm×H(20-90)mm (special size can be customized) |

| Cardboard requirements for packages | 250-450g/㎡ (according to size of package) |

| Motor power | 1.5kw |

| Power supply | 380V 50HZ |

| Maximum noise | 75dB |

| Minimum Air pressure | 0.6Mpa |

| Air consumption | 120-160L/min |

| Overall dimension | L4200mm×W1350mm×H1900mm |

| Weight | 1500Kg |

Range of application

- Stationery packaging: pen, chalk, crayon, stapler, playing cards, ink paste, building blocks, etc.

- Pharmaceutical packaging: oral liquid, medicine bottle, vial, bagged granule, antipyretic patch, etc.

- Food packaging: ice cream, wafer roll, biscuits, chocolate, pastries, bagged coffee, tea bags, etc.

- Daily necessities packaging: toothpaste, cosmetics, perfume, facial mask, antipyretic patch, condoms, pregnancy test paper, mosquito-repellent incense, etc.

- Fragile items packaging: bearings, bulbs, switches, sockets, electric relay, chargers, etc.

- Auto parts packaging: spark plugs, filters, piston rings, automotive bulbs, automotive appliances, valves and so on.

- Tissue paper packaging: napkin, tampon, pads, cotton pads, etc.

Main parts list

| Item | Name | Model and specification | Origin | QTY |

| 1. | PLC | CPIE-N30DT-D | Japan Omron | 1 |

| 2. | PLC Extended Module | CPIE-C1F11 | 1 | |

| 3. | Touch Screen | NB7W-TWOOB | 1 | |

| 4. | Inverter | 3G3JZ-A4015 | 1 | |

| 5. | Photoelectric Sensor | SICK 121 | SICK | 4 |

| 6. | Motor | CH-1500-10S 1.5KW | Taiwan CPG | 1 |

| 7. | Index Drive | 0S83-4L-180 | Zhejiang | 1 |

| 8. | Button | XB2 | France Schneider | 3 |

| 9. | Emergency Stop | ZB2 BC4D | 1 | |

| 10. | 5 relay | Zhejiang | 1 | |

| 11. | 8 transistor | 1 | ||

| 12. | Solenoid Valve | 4V210-08 | AirTAC | 2 |

| 13. | Air Filter/Regulator/ | BFR-2000 | 1 | |

| 14. | Proximity switch | TL-Q5MC1 | Japan Omron | 2 |

| 15. | Sucking disc | VF-30 | Korea | 2 |

| 16. | Vacuum Generator | ABM20-C | SMC | 1 |

| 17. | AC contactor | LC1E3210M5N | France Schneider | 1 |

| 18. | Switching power supply | PMC-24V 050V | DELTA | 1 |

| 19. | Air switch | 3P32A 1P10A | France Schneider | Each1 |

| 20. | Encoder | B-ZSP3806E2C | Japan Omron | 1 |

| 21. | Cover | Stainless Steel | Shanghai | 1 SET |

Hemp rope is all right while iron chain and wire rope should not be used. All the overhanging parts of the machine should be strapped by the rope, and the machine's surface must be protected by elastic items such as rubber or sponge. Solid board is needed to seal the whole machine firmly.

Installation

- This cartoning machine is a type of packaging equipment. It can be installed in rooms with good ventilation and adequate lighting.

- A spare distance of 1.5m is required around the machine for operation and maintenance.

- 380V-50HZ three-phase AC power supply and electrical grounding is necessary.

- It must be installed on a relatively flat ground. After installation, level of the machine should be checked by a gradienter. When it is not, you should adjust the four feet of the machine to keep it level.

- Every part should be checked if it is loose after being installed. Any mistake should be ruled out as soon as possible. To prevent rust, the machine is greased before being shipped. Thus, the excess grease on the surface should be cleaned before you run the machine. Cotton and alcohol is needed for the cleaning. After that, lubricating of certain parts is necessary.

Maintenance

- Keeping clean of the machine is necessary, and the rotating parts need to be cleaned and lubricated frequently.

- Cam structure and transmission chains should be lubricated every 15~40 hours. Motor oil of brand 50 is recommended (kinematic viscosity is around 47~53mm2/S50℃). Gear meshing parts should be lubricated every three months and Albany grease is recommended (ZG-1 or ZG-2).

- Cog belt and driving belt should not be contacted with grease, in order to lengthen its life span.

- To ensure regular and stable run of the machine, it should be shut down every three months to check the tension of the transmission chain and transmission parts. When it is necessary, you should adjust and fasten certain parts of it.

- Any breakdown of the machine should be carefully taken care of by professional mechanic. To avoid damage to any part of the machine, self dismantling is not allowed.