Ball Mill Liners

Main materials: Alloy steel, high chrome iron

Customizable or not: Yes

Product Description

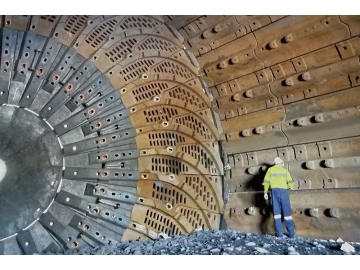

Ball Mill Liners

Ball Mill LinersThe grinding mill liners from HANDY are manufactured from high quality alloy steel or high chrome iron. From feed head to discharge end, the shell plate liners are specially designed for optimization of mill performance and perfect fit with the mill. In addition, we provide ideal alloy selection for the ball mill spare parts to suit your applications.

In wear resistant industry, Chromium, Mo and Nickel are added into carbon steel to achieve remarkable wear resistance and corrosion resistance properties. At HANDY, we divide alloy steel into 6 groups according to the element added:

1. Low chromium Alloy Steel (Cr2)

2. Medium Chromium Alloy Steel (Cr5)

3. Cr-Mo Alloy Steel (Cr5Mo)

4. Cr-Mo Ni Alloy Steel (Cr5MoNi)

5. Low carbon high chromium Alloy Steel (Cr8Cu)

6. Low carbon Mo-Cr-Ni Alloy Steel

| Name | C | Mn | Cr | Si | S,P | Cu | Mo | Ni |

| Cr2 | 0.3-1.2 | 0.3-1.5 | 1.0-3.0 | 0.3-1.5 | ≤0.06 | |||

| Cr5 | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | |||

| Cr5Mo | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | 0.3-1.0 | |

| Cr5MoNi | 0.3-0.65 | 0.3-1.2 | 4.0-6.0 | 0.3-1.2 | ≤0.06 | |||

| Cr8Cu | 0.2-0.35 | 0.3-1.2 | 6.0-9.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | ||

| Cr8MoNiCu | 0.2-0.35 | 0.3-1.2 | 6.0-9.0 | 0.3-1.2 | ≤0.06 | 0.3-1.0 | 0.3-1.0 | 0.3-1.0 |

Mechanical Property after Heat Treating: 44-54HRC; 10-60J/cm2

| Designation | C | Mn | Cr | Si | S | P |

| Cr12 | 2.2~2.6 | 0.6~1.0 | 11.5~13 | 0.6~1.0 | ≤0.05 | ≤0.05 |

| Cr15 | 2.2~2.6 | 0.6~1.0 | 14.5~16 | 0.6~1.0 | ≤0.05 | ≤0.05 |