Veneer Dryer

Veneer dryer is a necessary plywood equipment used to minimize the moisture content of veneer and protect the veneer made final product from expansion or decay. According to different methods of drying, our veneer dryer includes platen dryer and belt dryer; the platen dryer is mainly used to dry thick veneer and core veneer and the belt dryer is mainly used to dry the thin veneer and face veneer.

Performance

1. Our veneer drying machine has its method of thermal recycle comparable with that of the advanced European drying equipment.

2. The adopted vertical volute centrifugal fan has the flow rate up to 45,000- 62,000 m3/h.

3. New heat exchanger and the rectangular sprayer tank with variable cross-section can make the high-speed jet stream evenly act on the veneer surface.

4. Hot-air blower is designed with separate heating chambers in the front and at the back, which can ensure the dried veneer has consistent moisture content.

5. In order to cope with the hot and humid tropical climate, our veneer dryer has appropriately lengthened open section to facilitate the cooling and prevent the veneer from getting damp.

6. The thermodynamic cycle system of our veneer dryer uses steam or heat transfer oil as the heating medium.

When using the heat transfer oil, please pay special attention to the security and be aware of fire caused by the carbon deposition on the pipeline of the thermal cycling system and the heat exchanger. Please avoid water, acids or substances having low boiling point entering the system.

Structural Features

1. Frame:

Having the frame made of premium special shaped steel, this woodworking machinery has high rigidity, secured connection and simple structure for easy installation.

2. Sprayer tank:

Made of premium cold rolled sheet steel, the sprayer tank has good rust resistance and corrosion resistance; its variable cross-section and consistent jet stream ensures the veneer has consistent moisture content.

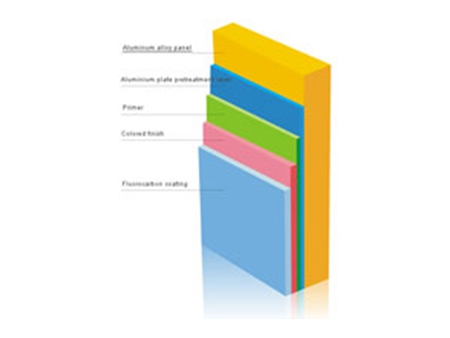

3. Thermal insulation panel:

The thermal insulation panel consists of two cold rolled sheet steel layers and is filled with high-density cotton batts. It has flat and elegant appearance and is durable in use. The connecting rod locking mechanism and the high temperature resistant silicon foam sealing strip have excellent sealing performance.

4. Hot-air blower:

Thanks to the German technology, the hot-air blower has large flow and makes low noise; the imported bearing has high reliability and is easy to lubricate; the 5V triangle belt has high transmission efficiency and good durability.

5. Driving motor:

this wood processing equipment uses variable speed motor and frequency converter.

6. Heating system:

the cooling fin is made of high-quality steel and aluminum composite material; under the normal wind speed, the heat conductivity coefficient (K) is up to 58, which is 30% higher than that of similar products in China. We have asked the No. 614 research institution of Department of Aviation to design low-resistance optimized structure to ensure the energy-efficient technical features of our heating system. The adopted Britain Spiraxarco steam trap saves the energy by 25%; a fixed number of Spiraxarco steam traps are provided for customers for low maintenance.

7. Electronic control system:

It uses French SCHNEIDER ELECTRIC branded electric elements, which feature rational layout, aesthetic appearance and easy operation.

8. Pneumatic elements:

Pneumatic elements are of famous brand in Taiwan.

9. The internal components:

The internal components are coated with iron oxide red anticorrosive paint and high temperature resistant silver paint; after installation, the internal components are finished with CARBOLINE branded green epoxy wrinkle paint.

Parameters

| Working width | mm | 4400 |

| Quantity of layer | 4 | |

| Length of drying section | mm | 6×2000 = 20000mm |

| Length of cooling section | mm | 1×2000 = 4000mm |

| Platen speed | m/min. | 1.5 to 15 |

| Drying speed (veneer thickness = 3.6mm) | m3/h | Approx. 2.0 |

| Note: when drying the gum wood, the drying speed is 15%-20% lower | ||

| Steam consumption | Mil Kcal/h | 2450 |

| Compressed air pressure | Mpa | 0.4 a 0.5 |

| Compressed air consumption (Free state) | m3/min | 1.0 |

| Dimensions (L×W×H) (Without drying and ventilation mechanism) | mm | 40165×6800×4772 |