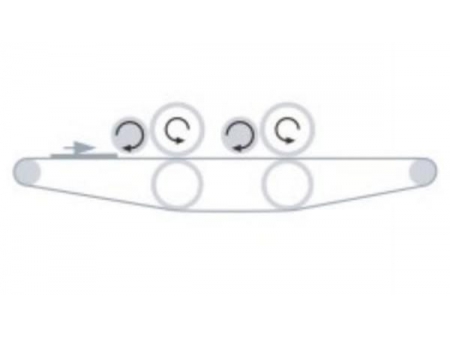

Double Roller Color Coating Machine

Request a Quote

SurSurface finishing system for applying color coating on wood panels

The double roller roll coater is designed with a high-density sponge roller to complete colorant transfer coating. The sponge roll has a high water absorption rate and excellent wear resistance, making it ideal for water and oil based paints that traditionally have a poor adhesion.

A wide range of substrates are applicable to this machine, including furniture boards, wooden doors, cabinet panels, floors, inorganic plates, and more.

Working principle

The doctor roll ensures the colorant is evenly distributed on the sponge roll, thus ensuring the colorant applied to the produce surface is even.

Specifications

| Effective processing thickness | 2-80mm |

| Effective processing width | 620/920/1320mm(optional) |

| Minimum processing length | 300mm |

| Transport speed | 0-20m/min |

| Heating power | 3kW |

| Power supply | 380V/50Hz |

| Paint type | Water-based/Oil-based |

Features

- The products coated using this machine feature an even surface coloration.

- Water-based or oil-based paints are used, which can be quickly dried and are efficient, green and environmentally friendly.

Optional models

SR-R2H series Coloration Coating Machine

| Model | Effective processing width (mm) | Conveying power (kw) | Power of coating roll (kw) | Power of doctor roll (kw) | Outline size (L*W*H) |

| 620 | 0.75 | 0.75 | 0.55 | 1800*1850*1700 | |

| 920 | 0.75 | 0.75 | 0.75 | 1800*2150*1700 | |

| 1320 | 1.5 | 1.5 | 0.75 | 1800*2450*1700 |