MR6-300G (for Grain)

Automatic Rice Packaging Machine Price, Rotary Food Packaging Machine, Coffee Packaging Machine

MR6-300G--Grain Packing Machine

Product Name: Automatic packing machine

Model: MR6-300F

Categories: Pouch, bag fill and seal packing machine/MR6-300F Powder Packing Machine

Parts: , ,

Main Features of Pre-Made Pouch Filling and Sealing Machine

1. Full automatic 6-station intermittent rotary performed bags dispensing,opening and closing machine combines

2. Safety guard protected for high speed and consistent production.

3. Heavy duty components and parts are selected for machine durability.

4. Hygienic construction and easy cleaning. Operator friendly design touch-screen control system.

5. Versatile in design, easy to link up with other down stream packaging equipment, such as liquid filler, powder filler, multiheads weigher, metal detector, check weighter, case sealer etc.

6. Innovative and practical solution at reasonable costs.

7. Dust control and extractor system on special request.

Typical Flow Chart of Pre-Made Pouch Filling and Sealing Machine

1. Bags dispensing

2. Hot Foil Coding

3. Bags Opening

4. Dosing

5. Heating sealing

6. Discharge

| Model | MR6-300 |

| No. of working station | Eix |

| Bags size | W:80-200 L:no limit |

| Filling Volume | 5-1500g(depending on type pf product) |

| Packaging Materials | Zipper bag, stand-up bag, spout bags etc |

| Capacity | 60bags/min(depending on type of product and packaging material used) |

| Total power consumption | 5Kw |

| Weight accuracy | R≤±1 |

| Type | Filling Machine |

| Condition | New |

| Application | Beverage, Food |

| Packaging Type | Bags, Film, Foil, Pouch, Stand-up Pouch, bag |

| Packaging Material | Plastic |

| Automatic Grade | Automatic |

| Driven Type | Mechanical |

| Voltage | 380V/220V |

| Power | 3.5kw |

| Place of Origin | Zhejiang, China (Mainland) |

| Brand Name | Echo |

| Model Number | MR6-300 packaging machine |

| Certification | CE, ISO9100 |

| After-sales Service Provided | Engineers available to service machinery overseas |

| Packaging machine Material | Stainless steel |

| Automatic packaging machinery | Rotary packaging machinery |

| Rotary packaging machinery | Powder packaging machine |

| Packaging machinery for food | Powder filling and sealing machine |

| Pemade packaging machine | Auto rotary packaging machine |

| Filling and sealing packaing machinery | Food Auto packaging machinery Echo |

| Food Rotary packing machine | Automatic Food Packaging Machinery |

| Coffee Powder Rotary Packing Machine | Fill-Seal Packing Machine for Coffee Powder |

| Rotary packing machine | Zipper and stand-up pouch packing machine |

| Packaging Details | Soild pouch packing machine W ooden case |

| Delivery Detail | 30 days |

1. 10-Head Computer Weigher

Features of 10-Head Computer Weigher

1)Suitable range: dosing and weighing of grain, chip, bar or irregular shaped material such as candy, sunflower seed, potato chip, happy fruit, peanut, jelly, freezing rice dumpling, biscuit, chocolate, nut, pet food, puffed food, small metal parts and plastic parts, etc.

2) Select the optimum combination immediately from plenty weighing combinations by powerful software.

3) Adopt high precision digital weighing load cell and A/D module to get precise weighing than before.

4) LCD operating display with multiple languages such as English, Russian, German, Spanish, Italian, etc.

5) IP65 whole waterproof and dustproof design. It's easy to clean and maintain.

6) The powerful ability of Automatic Feeder Control to make the machine self-adjusting during running.

7) Provided with strong operation memu to make you study and operate more easily. Powerful automatic data statistical function.

8) Optional devices: triply balance ball, suction hopper, printing device, tolerance sorting device.

9) Strong compatibility and more compact structure with it directly installed on the upper part of packing machine.

10) Fast return for investment by largely saving large quantity of raw material and labour cost.

11) Net weight: 300kg; Gross weight: 370kg

12) Voltage: 220V; Power: 1500W; Frequency: 50/60HZ; Rated current: 9A.

13) Out package dimension(mm): 1400(L)×1130(W)×1120(H)

| Weighing range | 10-1000g |

| Maximum weighing quality | 3000g |

| Average tolerance for single bag | 0.2-0.5g |

| Range of weighing precision | 0.1-1.5g |

| Maximum weighing speed | 70 bags /minute |

| Hopper capacity | 1300ml |

| Hopper type | Bi-row hopper without memory |

| Driving | Step motor |

| Preset number for product | 99 kinds |

| Size of machine body(mm) | 1150(L)X950(W)X1129(H) |

2. Z Type Conveyor

Features of Z Type Conveyor

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc.For the lifting machine, the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

| Highness of lifting | 3m -10m |

| Speed of lifting | 0-17m/minute; |

| lifting quantity | 5.5cubic meter/hour |

| Power | 750w |

| Remark | Specification customized; material: carbon steel plastic-spray or stainless steel; the part contacting with food is food grade plastic. |

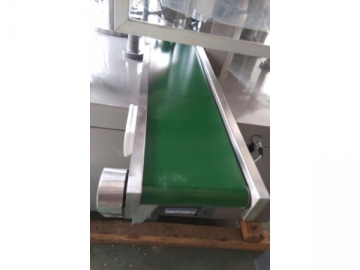

3. Finished Products Conveyor

Features of Finished Products Conveyor

The machine can send the packed finished bag to after-package detecting device or packing platform.

| Lifting height | 600-800MM |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30m/minute |

| Dimension | 2110 ×340×500mm |

| Voltage | 220V/45W |