Twin Shaft Concrete Mixer

Introduction:

The twin shaft concrete mixer is suitable for various constructional engineering, factory for prefabrication and concrete block brick manufacturer. It can be used for mixing of hard concrete, plastic concrete, flowing concrete, light-weight aggregate concrete and various mortar.

The blade adopts new screw type arrangement, so the mixing time is long, the mixing is uniform, satisfying the requirements of different working conditions.

Application:

The twin shaft concrete mixer features compact structure and wide application. It can be used for rapid mixing of large batch of concrete such as commercial concrete, concrete which is used on site or for casting. The diameter of the aggregate mixed can be up to 150mm.

The solid structure and the powerful mixing device can effectively ensure the long service life and low maintenance cost.

| Item | Loading capacity | Loading capacity | Discharging capacity | Mixing power | Discharging power | Machine weight |

| L | Kg | L | Kw | Kw | Kg | |

| 750 | 1200 | 500 | 18.5 | Pneumatic | 3900 | |

| 1125 | 1800 | 750 | 30 | 4300 | ||

| 1500 | 2400 | 1000 | 37 | Pneumatic or 2.2 | 5075 | |

| 1875 | 3000 | 1250 | 45 | 5250 | ||

| 2250 | 3600 | 1500 | 55 | 5430 | ||

| 3000 | 4800 | 2000 | 2*37 | 3 | 8200 | |

| 4500 | 7200 | 3000 | 2*55 | 3 | 9700 | |

| 6000 | 9600 | 4000 | 2*75 | 4 | 12000 | |

| 9000 | 14400 | 6000 | 4*55 | 5.5 | 19500 |

Performance features:

1. The mixer features compact structure so that it needs less floor area, thus the machine installation and equipment upgrading can be convenient.

2. This concrete mixer adopts the combined structure of dual floating oil sealing ring, specific sealing elements and high pressure oil, thus prolonging the service life of the shaft-end sealing device and effectively avoiding concrete leakage.

3. It adopts superior high pressure lubricant pump. All the lubricating points are lubricated by the dispenser which features precise dosage and high reliability.

4. The mixing tank is more solid according to the design, thus ensuring that it will not deformed permanently.

5. The streamlined stirring arms are arranged into discontinuous helical line along the mixing shaft. Thus, the axial and radial mixing trail forms a 3D mixing trail. This structure can reduce mixing time and power consumption at the same time.

6. This mixer can be equipped with optional high pressure cleaning device and moisture content meter.

7. Hongyi can provide all-round technical supporting from optimal model selection, personalized customization which can be applied in special occasions and maintenance and some other services.

1. Shaft-end sealing device

This concrete mixer adopts the combined structure of dual floating oil sealing ring and high pressure oil, thus prolonging the service life of the shaft-end sealing device.

2. Automatic lubricating system

It adopts superior high pressure lubricant pump. All the lubricating points are lubricated by the dispenser which features precise dosage and high reliability.

3. Access door

The large access door enables convenient maintenance and cleaning. It is equipped with self-locking safety device.

4. Transmission device

The reducer adopts planet-gear speed reducer imported from Italy for transmission. This reducer features low noise and long service life.

5. Manual centralization lubrication

All the lubricating points which should be lubricated manually are gathered together, thus ensuring that no lubricating point will be missed.

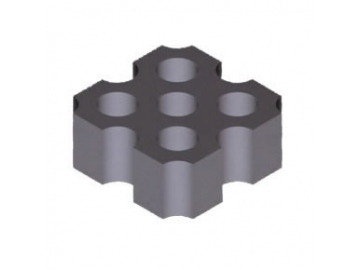

6. Mixing device

The mixing blade is made of high nickel cast iron so that the mixing speed is faster and the service life can be longer.

7. Safety device

The mixer adopts scram button and safety switch which can realize emergency machine stop.

8. Hydraulic unloading device

The hydraulic discharging device is equipped with manual door opener which allows manual door opening when the power is off.

Note: the parameters above is for reference only because the products are continuously improved.