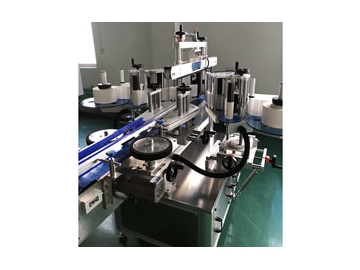

AS-S06 Inline Labeling Machine

Our inline labeling machine was specially developed for flat surface labeling. It can work in combination with various production lines such as carton packing lines. Its maximum production speed can reach 200 pcs/min.

The equipment can be outfitted with optional ribbon printers and industrial inkjet printers. They can be used to apply the production date and batch number on the label to complete high efficiency labeling and printing.

Applications

- Applicable labels: self-adhesive label, self-adhesive film, electronic supervision code, bar code, etc.

- Applicable products: products with flat side surface.

- Applicable industries: pharmaceutical, cosmetics, electronics, hardware, plastic, etc.

- For example: apply labels on the lateral surface of motor, carton, rice cooker, tire, etc.

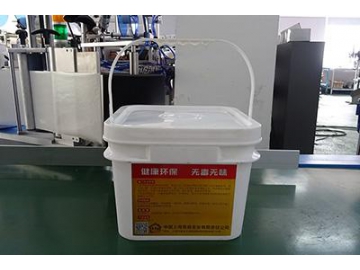

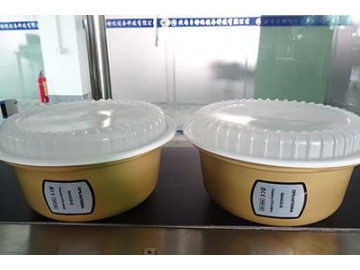

Samples

Specification

| Model | AS-S06 |

| Label stop accuracy | ±1mm |

| Production speed | 40-200 pcs/min |

| Product diameter | Customized |

| Product width | 6mm~250mm |

| Label length | 20mm~280mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 1100mm x 700mm x 1450mm |

| Weight | 70Kg |

| Air pressure | 0.4-0.6Mpa |

Details of Inline Labeling System

Photoelectric sensor:

Photoelectric sensor:

The labeling machine is equipped with a photoelectric sensor made by Sick which features high precision and high reliability. Touch screen:

Touch screen:

Controlled by PLC, the interface is convenient to use. With just a tap of its touch screen, you can easily access various functions and parameters for your product needs. Easy to apply:

Easy to apply:

It can be installed on the production line directly to realize fully automated production operations. It supports independent control and linkage control.

Related products

Send Message

Most Recent

More

Other Products

Videos