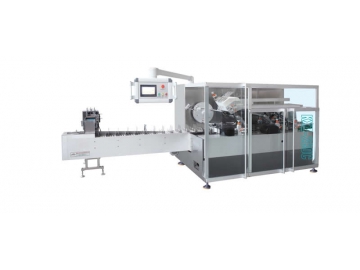

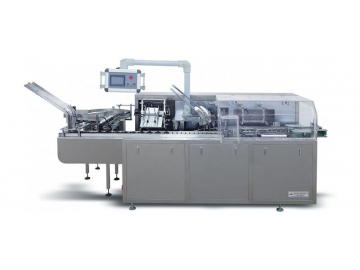

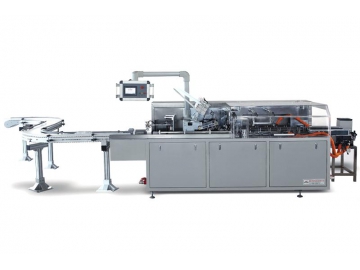

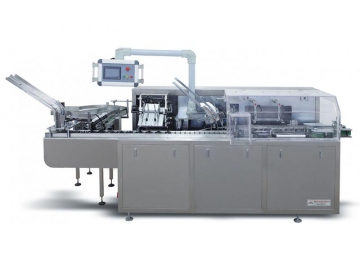

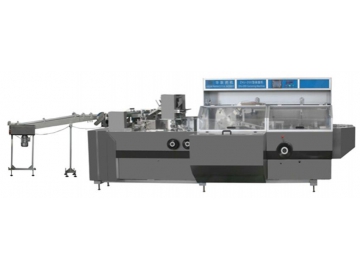

KXZ-280C High Speed Cartoning Machine (Cartoner)

Introduction

The KXZ-280C high speed cartoner is a fully automatic cartoning machine which can run at high-speeds in a continuous mode. This packaging machine operates with high stability and pack 280 cartons per minute, which is 2-3 times faster than ordinary cartoners. Our machines are extremely efficient. Packaging is completed in a steady process, while the noise and load are minimized.

The cartoning machine adopts a suspended structural design. It has an innovative compact design with convenient maintenance access, allowing operators to get close to the equipment easily and clean or replace components. The suspended structure of the whole machine lets waste fall to the collection unit below, making it easy to keep clean. The whole machine is made of stainless steel and features a closed circuit and gas path structure. The driving device is located at the rear and is completely open on the operator side, which meets GMP standards.

Features

- This cartoner performs packaging in a continuous and fully-automatic mode with a speed of 160-280 cartons per minute.

- The conveyor belt is 1600mm long.

- The cover is made of 304 stainless steel with an aluminum alloy tempered glass protective door.

- The machine features a man-machine interface to adjust every step conveniently. It has the functions of statistical monitoring and will display any errors while sounding an alarm.

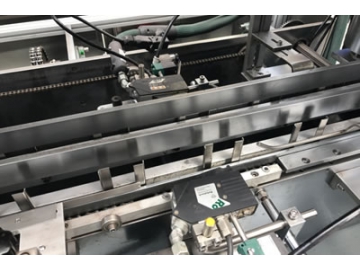

- The PLC and electro-optical tracking system are applied to monitor the process of packaging. The machine will alert users of errors like when the equipment runs out of cartons or if there is a paper jam. When such problems occur, an alarm will sound to alert the operator. The number of products cartoned is displayed on this system.

- The packaging machine adopts several reliable mechanical and automatic overload protection devices, which enable the machine to protect itself and avoid damage during operation.

- There is no need to change parts of the machine while changing the type of packed items. The changes can be completed by directly adjusting certain parts. Every part can be firmly adjusted by a handle manually. It is simple to adjust without the need of tools.

Product Loader

Stainless steel materials, It’s up to medical standard

Carton Box Loader

It can be adjusted according to different box size

Three-head Box Opening Device

Faster and more stable

Carton Close Device

It’s more beautiful within a black box

Switzerland Robatech Hot Melt Glue Sealing(Optional)

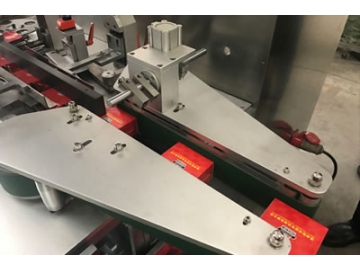

Finished Products Output Device

| Packing Speed | 50-280 cartons/min | |

| Carton specifications | Weight | 250-450g/m² (according to its dimensions) |

| Dimension (L x W x H) | (100-250)mm×(60-130)mm×(20-70)mm (Special size can be customized) | |

| Compressed air | Working pressure | ≥0.6Mpa |

| Air consumption | 20m³/h | |

| Power supply | 380V 50Hz | |

| Motor power | 1.5kw | |

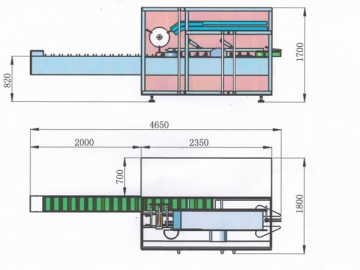

| Overall dimension (LxWxH) | 5000 x 1700 x 1900mm | |

| Machine weight | 2000KGS | |

Range of application

- Stationery packaging: pen, chalk, crayon, stapler, playing cards, ink paste, building blocks, etc.

- Pharmaceutical packaging: oral liquid, medicine bottle, vial, bagged granule, antipyretic patch, etc.

- Food packaging: ice cream, wafer roll, biscuits, chocolate, pastries, bagged coffee, tea bags, etc.

- Daily necessities packaging: toothpaste, cosmetics, perfume, facial mask, antipyretic patch, condoms, pregnancy test paper, mosquito-repellent incense, etc.

- Fragile items packaging: bearings, bulbs, switches, sockets, electric relay, chargers, etc.

- Auto parts packaging: spark plugs, filters, piston rings, automotive bulbs, automotive appliances, valves and so on.

- Tissue paper packaging: napkin, tampon, pads, cotton pads, etc.

Main parts list

| Item | Name | Model and specification | Origin | QTY |

| 1. | PLC | CPIE-N30DT-D | Japan Omron | 1 |

| 2. | PLC Extended Module | CPIE-C1F11 | 1 | |

| 3. | Touch Screen | NB7W-TWOOB | 1 | |

| 4. | Inverter | 3G3JZ-A4015 | 1 | |

| 5. | Photoelectric Sensor | SICK 121 | SICK | 4 |

| 6. | Servo motor | ECMA-20604RS 0.4KW | DELTA | 1 |

| 7. | Servo-drive | ASD-B2-0421-B | DELTA | 1 |

| 8. | Index Drive | 0S83-4L-180 | Zhejiang | 1 |

| 9. | Button | XB2 | France Schneider | 3 |

| 10. | Emergency Stop | ZB2 BC4D | 1 | |

| 11. | 5 relay | Zhejiang | 1 | |

| 12. | 8 transistor | 1 | ||

| 13. | Solenoid Valve | 4V210-08 | AirTAC | 2 |

| 14. | Air Filter/Regulator/ | BFR-2000 | 1 | |

| 15. | Proximity switch | TL-Q5MC1 | Japan Omron | 2 |

| 16. | Sucking disc | VF-30 | Korea | 2 |

| 17. | Vacuum Generator | ABM20-C | SMC | 1 |

| 18. | AC contactor | LC1E3210M5N | France Schneider | 1 |

| 19. | Switching power supply | PMC-24V 050V | DELTA | 1 |

| 20. | Air switch | 3P32A 1P10A | France Schneider | Each1 |

| 21. | Encoder | B-ZSP3806E2C | Japan Omron | 1 |

| 22. | Cover | Stainless Steel | Shanghai | 1 SET |

Hemp rope is all right while iron chain and wire rope should not be used. All the overhanging parts of the machine should be strapped by the rope, and the machine's surface must be protected by elastic items such as rubber or sponge. Solid board is needed to seal the whole machine firmly.

Installation

- This cartoning machine is a type of packaging equipment. It can be installed in rooms with good ventilation and adequate lighting.

- A spare distance of 1.5m is required around the machine for operation and maintenance.

- 380V-50HZ three-phase AC power supply and electrical grounding is necessary.

- It must be installed on a relatively flat ground. After installation, level of the machine should be checked by a gradienter. When it is not, you should adjust the four feet of the machine to keep it level.

- Every part should be checked if it is loose after being installed. Any mistake should be ruled out as soon as possible. To prevent rust, the machine is greased before being shipped. Thus, the excess grease on the surface should be cleaned before you run the machine. Cotton and alcohol is needed for the cleaning. After that, lubricating of certain parts is necessary.

Maintenance

- Keeping clean of the machine is necessary, and the rotating parts need to be cleaned and lubricated frequently.

- Cam structure and transmission chains should be lubricated every 15~40 hours. Motor oil of brand 50 is recommended (kinematic viscosity is around 47~53mm2/S50℃). Gear meshing parts should be lubricated every three months and Albany grease is recommended (ZG-1 or ZG-2).

- Cog belt and driving belt should not be contacted with grease, in order to lengthen its life span.

- To ensure regular and stable run of the machine, it should be shut down every three months to check the tension of the transmission chain and transmission parts. When it is necessary, you should adjust and fasten certain parts of it.

- Any breakdown of the machine should be carefully taken care of by professional mechanic. To avoid damage to any part of the machine, self dismantling is not allowed.