Germany Technology Best Service

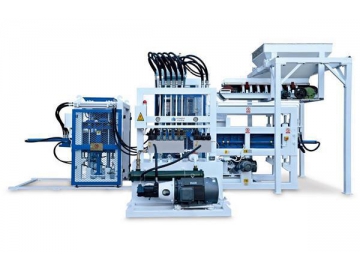

- It is applicable to the production of larger blocks, such as road traffic stone, large-scale water conservancy and hydraulic products, municipal pavement bricks and revetment block, etc.

- Four-axis synchronous vibration system configuration as well as special self-lubrication design can reduce the number of times of shutdown repairing and increase the service life of vibrator.

- Air bag device can reduce the impact loss of vibration on the machine and improve the quality of finished products.

| Overall dimension | 5300×2450×2850mm | Vibration method | Synchronous mode of table & mould |

| Pallet size | 1400×950×45mm(Wooden) | Vibration frequency | 50-70Hz |

| Working area | 1300×900mm | Machine Power | 62kW |

| Machine weight | 15500kg | Cycle time | 15s-25s |

| Specification of products (mm) | Number of blocks per pallet | Pieces/hour | Pieces/8 hours | Pieces/300 days (two shifts) | ||

| Block | 390×190×190 | 12 | 2,880 | 23,040 | 13,824,000 | |

| Hollow Brick | 240×115×90 | 30 | 7,200 | 57,600 | 34,560,000 | |

| Paving Brick | 225×112.5×60 | 30 | 7,200 | 57,600 | 34,560,000 | |

| Standard Brick | 240×115×53 | 60 | 14,400 | 115,200 | 69,120,000 | |

Related products

Send Message

Most Recent

More

Other Products

Videos