Concrete Cooling

The internal temperature of concrete will rise faster in the process of coagulation and hardening since this process will generate much hydration heat. However, the concrete is of low thermal conductivity and fast surface heat dissipation, which makes a large temperature difference between the inside and outside of the concrete and cause a tensile stress on the surface of concrete. When the tensile stress exceeds a certain limit, the concrete surface will crack.

It is true that artificial cooling is one of the most popular ways to prevent concrete from cracking, however, it is vital to know that pre-cooling of aggregate and mixing the cold water and ice with concrete can significantly reduce the temperature of outlet concrete to control the concreting temperature.

In addition, as for the pouring of mass concrete, we also recommend you embed pipes in the concrete for flowing cooling water to reduce the temperature inside.

Providing You Turnkey Solution

We able to provide you with one-stop solution for concrete cooling system. Currently, we have manufactured and installed more than 1500 concrete cooling systems worldwide, including many famous projects, such as the world's tallest building in the United Arab Emirates (Khalifa Tower), Saudi North-South Railway, Mecca Light Rail, Doha New Port, Zhejiang Sanmen Nuclear Power, Qinshan Nuclear Power, Haiyang Nuclear Power, Brazil Hydropower Station, Hong Kong-Zhuhai-Macao Bridge, etc.

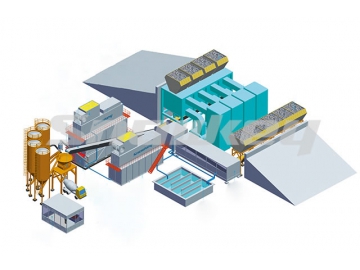

AN OVERVIEW OF A CONCRETE COOLING SYSTEM

• Water cooling and post-cooling(CW≤5℃)

• Water Chilling Plant(ICW≤1℃)

• Ice Plant(15~106Tons/day)

• Ice Storage Bin(AIS8~150Ton)

• Ice Delivery and Weighing(TSL.ID.LWT.QWT...)

• Cold Water Tank and steel frame

Ice Plant

Ice Plant  Ice Delivery and Weighing

Ice Delivery and Weighing Belt conveyor

Belt conveyor  Output temperature detection

Output temperature detection