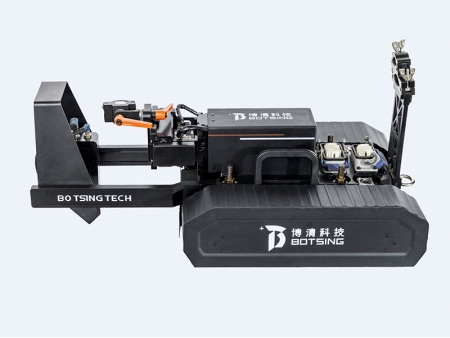

Trackless Unguided All-position Crawling Welding Robot

Trackless Unguided All-position Crawling Welding Robot is an automatic welding system being used for all-position(1G-6G) welding on large-scale structural parts, pressure vessels and storage tanks in industries like: oil & gas, offshore, shipbuilding, construction, nuclear, and many more. The trackless design provides flexible movement, and laser vision tracking system ensures high seam tracking accuracy, ensuring high welding efficiency and excellent welding quality. In addition, automatic recognition system of welded seams provides effective robot guidance. All these features make it an excellent solution compare with semi-automatic welding and manual welding.

Do you have any questions about our Robotic Welding Systems?

Contact us and one of our experts will be glad to help you.

- Crawler

- Laser vision seam tracking system

- Windproof shield

- Multiple DOF welding swing system

- Load-bearing device

- Permanent magnet adhesion walking mechanism

- Welding amateurs could operate one or more robots after 3-day professional training which reduces the number of operators and level of skills.

- No need for setting up guiding tracks or programming.

- Stable and reliable Welding quality which significantly reduces rework

- Low frequency pulse and program integrated double pulse welding procedures, high deposition rate, and greatly improved welding efficiency.

- Welding procedures stored locally at your fingertips

- High load capacity, flexible movement, able to achieve multiple-degrees-of-freedom full position free crawling and spin turn on medium and large structural parts

- Capability to cross obstacles

- Remote control by control cabinet with molten pool observation camera installed on crawler;

- Rugged design, built to last

- Equipped with four ultrasonic sensors with drop or falling prevention warning;

- Welding bojects: storage tanks, spherical tanks, vessels, nuclear power infrastructure and other large-sized structural parts

- Metal type: Carbon steel and alloy steel

- Welding groove type: V,X,U,J

- Welding positions:1G,2G,3G,4G, 5G,6G

- Metal thickness: 6mm to 100mm

All system components are mounted on the transfer trolley, including crawling welding robot, control cabinet, power source, wire feeder and water cooling unit, allowing for convenient operation and transportation.

- Transfer trolley

- Control cabinet

- Trackless unguided crawling welding robot

- Wire feeder

- Water cooling unit

- Welding power source

- Dimensions:1400(L)mmx800mm(W)xl500mm(H)

- Drive type:Electric/manual

The control cabinet features modular design, metal housing and touch screen control panel. Its high-performance CPU adopts a multiprocessor system, enabling high-speed synchronous operation of the crawler and actuator. A servo controller is installed in the cabinet, and the drive and control of each axis are connected to the CPU through the physical interface. The control cabinet is designed with a variety of interfaces to connect with various types of industrial equipment.

| Dimensions | 580mm (L) x360mm (W) x630mm (H) |

| Interfaces | Analog interface: 4 I/O Digital interface: 32 I/O |

With a maximum observation distance of 100m, the camera on the molten pool is used for remotely monitoring open arc welding process. A 140 dB dynamic range is achieved because of the advanced sensing technology and precise electrical circuit design. Users can clearly observe the welding torch, welding wire and the whole welding process by means of the camera on the molten pool.

| Image sensor | 2/3" color HDR CMOS |

| Resolution | 1280(H) X1024(V) |

| Pixel size | 6.8μm X 6.8 μm (8.7mm X 7mm effective area) |

| Filter | blocks UV IR |

| Image sensor shutter | global or rolling |

| Dynamic range | 140 dB |

| Pixel depth | 8bit |

| Exposure time | 100μs - 100ms |

| Image control | Shutter speed controls exposure time |

| Dimensions | 85mm (L) X36.5mm(W) X38.5mm (H) (lens excluded) |

| Weight | 200g (lens excluded) |

| Lens mount | C mount |

| Power consumption | 6W at 12V |

Welding power source can be configured according to customer's requirements. The standard version is digital series power source, which is integrated with more than 200 program memories. This makes welding material, wire diameter and gas work always at excellent performance level.

| Welding current | BQT-I-400A | BQT-I-500A | |

| Input voltage 50/60hz | 400v( 20%/-20%) | ||

| Input current | 25A | 28.5A | |

| Power factor at maximum current | 0.96 | 0.93 | |

| Efficiency at maximum current | 0.89 | 0.89 | |

| Duty cycle@40℃ | 100% | 420A | 500A |

| 60% | 350A | 450A | |

| Duty cycle@25℃ | 100% | 420A | 500A |

| Current range (MIG/MAG) | 15A-420A | 15A-500A | |

| Weight | 34KG | 40KG | |

| Dimensions | 738mm(L) *273mm(W) *521mm(H) | ||

The wire feeder is designed with a metal housing, ensuring high durability. With storage of 99 welding programs, this wire feeding unit is applicable to various welding applications.

| Model | DVU W500 |

| Weight | 16kg |

| Dimensions | 603mm(L)x262mm(W)x446mm(H) |

| Number of wire feeding rolls | 4 |

| Wire diameter | 0.6 mm-1.6 mm |

| Feeding speed | 0-25 m/min |

| Wire reel diameter | 300mm |

| Product weight | 28.8kg | Max. obstacle crossing height | 5mm |

| Max. load | 60kg | Max. travel speed | 5m/min |

| Min. diameter of curved surface | ≥3.2m | Weld tracking accuracy | ±0.5mm |

| Dimensions | 621 mm (L) x394mm (W)x267mm (H) | ||

| Crawler | with caterpillar track | Torch motion types | linear, pendulum, oblique |

| Linear motion range of welding torch | ±25mm | Stick-out range | ±25mm |

| Torch travel angle (pendulum motion) | ±30° | Torch oblique angle | ±10° |

| Torch pitch angle | ±30° | Rotation | spin around 360° |

| Working temperature | -10℃~40℃ | Relative humidity | below 90% |

| Control cable | 10m standard length; extended length available upon request | ||

Currently, welding of large-scale structural parts is performed mainly by manual or semi-automatic welding. A lot of hidden costs will be needed in the manual welding operation. A human welder needs to be trained for a long time to achieve sophisticated skills for quality welding operation. They may make mistakes during manual welding to affect production time, weld quality and costs. Manual welding may cause health and safety problems to the human welders due to the hazardous working environments full of flash, fumes, sparks, and heat. Semi-automatic welding in large structural components is affected by guiding tracks, which limits its degree of automation especially in the application scenarios with curved and irregular surface welds. Comparing with manual welding and semi-automatic welding, trackless unguided all-position robotic welding is an optimal alternative in the large-scale structural parts manufacturing industry, which can greatly improve welding quality and efficiency.

- Unstable weld quality

- Low efficiency

- High labor costs

- Pneumoconiosis

- Employee risks

- High management costs

- Guiding track needed

- Not applicable to the welding of irregular seam, especially curved surfaces