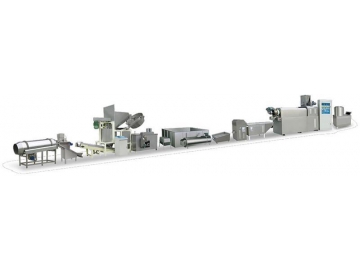

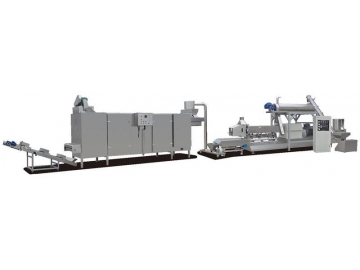

Screw Shell Food Processing Equipment Line

Introduction

The screw shell food processing equipment line is used to product popular second puffed foods with different shapes like spirals, shells, round tubes, square tubes, circles, and cartoon shapes from raw materials like potato starch, corn starch, flour by a special extrusion forming process.

| Model | Installed Power | Power Consumption | Throughput | Dimension | |

| SX2000-100 | 55KW | 45KW | 80-100kg/h | 15×1.2×1.8m | |

| SX3000-100 | 60KW | 50KW | 80-100kg/h | 16×1.5×1.8m |

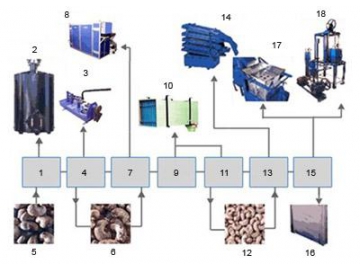

Equipment flowsheet

Flour mixer → Food process extruder with single screw → Conveyor cutting machine → Cooling bed → Hot air dryer → Automatic fryer→ Automatic seasoning line

Main equipment

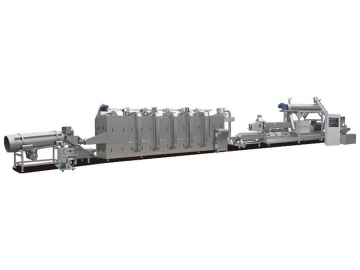

Food process extruder with single screw

Introduction

Food process extruder with single screw consists of a feeding system, extrusion system, rotary-cut system, heating system, drive system, cooling system and control system. It is used in fried food processing.

| Model | Installed Power | Actual Consumption | Main Motor Consumption | Thoughput | Dimension | Products | |

| SX2000-100 | 45KW | 28KW | 30KW | 80-100Kg/h | 3.5x1.05x1.96m | Second puffed foods | |

| SX3000-100 | 45KW | 30KW | 30KW | 80-100kg/h | 3.2x1.05x1.96m | Second puffed foods |

Automatic continuous food frying equipment

Introduction

Automatic continuous food frying equipment consists of a wire mesh belt conveying system, automatic lifting system, automatic filtering system, oil temperature automatic control system, automatic oil filling system, heating system. It is fully automatically heated by coal, gas, oil, electric, etc.

- It is designed with an automatic filtration system to clear residue in real-time so that the oil can remain clean and the fry quality can be optimal.

- The fryer is designed with automatic hoisting system. So it can be cleaned and maintained easily.

| Model | Installed Power | Actual Consumption | Main Motor Power | Throughput | Dimension | |

| SX65-IIIA | 35KW | 28KW | 22KW | 120-150kg/h | 2.5x1.0x1.8m | |

| SX65-IIIB | 60KW | 40KW | 22KW | 150-200kg/h | 3.5x1.0x1.8 | |

| SX85-II | 120KW | 60KW | 90KW | 300-500kg/h | 4.0x1.2x3.0 | |

| SX65-I | 70KW | 40KW | 30KW | 100-150kg/h | 3.5x1.0x1.8 |

TWD-I single roller seasoning machine

Introduction

It can be used to season all kinds of puffed and fried foods or inject oil and sugar.

- The roller of the seasoning equipment is made using compression molding with no dead angles.

- Seasoning materials are fed separately and measured accurately by the screw to ensure seasoning evenly.

| Model | Installed Consumption | Throughput | Dimension | |

| TWS-I | 2.2KW | 180-250kg/h | 3.6x0.9x1.7m | |

| TWD-I | 0.75KW | 150-200kg/h | 2.1x0.7x1.6m | |

| TWB-I | 0.75KW | 150-200kg/h | 1.4x1.1x1.6m |

Foreign trade business of Luerya

The quality of screw shell food processing equipment line is authenticated by CE. And it has been exported to many countries like Russia, Australia, Canada, Italy, Brazil, Argentina, India, Indonesia, Vietnam, Pakistan, Korea, South Korea, the Philippines, myanmar, Singapore, Malaysia, Iraq, Turkey, Egypt, Nigeria, Romania, Thailand, Mexico, Haiti, Cuba, Colombia, venezuela, Bolivia and so on.

Index

food processing equipment, commercial food machines, food manufacturing line, puffed food machines