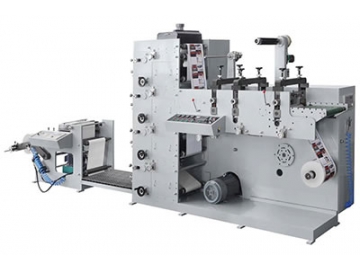

Flexo Printing Machine

Application of Flexo Printing Machine YRB

This flexo printing machine is suitable for printing packaging materials such as polyethylene, polypropylene bag, cellophane and roll paper, etc.

It is a kind of ideal printing equipment for producing paper packing bag like supermarket handbag, vest bag and clothes bag, etc.

Performance and Characteristics of Flexo Printing Machine YRB

1. Simple operation, flexible startup, precise color registration.

2. Printing quantity can be pre-set and the printing machine will stop work automatically when the pre-set quantity is reached.

3. Pneumatic printing cylinder lift: the printing ink will be stirred automatically after lifting.

4. Sensitization resin is used as flexible printing plate.

5. Automatic circuit cut-off when the machine stops: the flexo printing machine has reliable drying system and high rotation speed.

6. The longitudinal registration device is 360 degree adjustable.

7. The frequency control of motor speed can be adapted to different printing speeds.

8. Easy operation of the machine: there are jogging/stopping buttons on the plate roller base and material rolling rack.

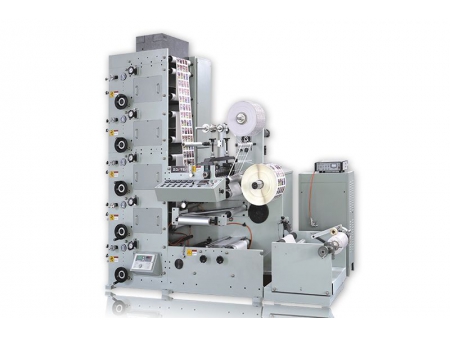

Technical Parameters of Flexo Printing Machine YRB:

This flexo printing machine is suitable for printing packaging materials such as polyethylene, polypropylene bag, cellophane and roll paper, etc.

It is a kind of ideal printing equipment for producing paper packing bag like supermarket handbag, vest bag and clothes bag, etc.

Performance and Characteristics of Flexo Printing Machine YRB

1. Simple operation, flexible startup, precise color registration.

2. Printing quantity can be pre-set and the printing machine will stop work automatically when the pre-set quantity is reached.

3. Pneumatic printing cylinder lift: the printing ink will be stirred automatically after lifting.

4. Sensitization resin is used as flexible printing plate.

5. Automatic circuit cut-off when the machine stops: the flexo printing machine has reliable drying system and high rotation speed.

6. The longitudinal registration device is 360 degree adjustable.

7. The frequency control of motor speed can be adapted to different printing speeds.

8. Easy operation of the machine: there are jogging/stopping buttons on the plate roller base and material rolling rack.

Technical Parameters of Flexo Printing Machine YRB:

| Type / Item | Printing Entrance Width(mm) | Printing Width(mm) | Length of Printing Product(mm) | Diameter of Roll Material(mm) | Printing Speed(m/min) | Thickness of Printing Plate(mm) | Total Power(Kw) | Machine Dimension (L×W×H)(mm) | Weight (kg) |

| YRB-6600 | 600 | 560 | 191-914 | 450 | 5-50 | 2.3 | 13 | 3900×1660×2950 | 3500 |

| YRB-6800 | 800 | 760 | 191-914 | 450 | 5-50 | 2.3 | 15 | 3900×1860×2950 | 4200 |

| YRB-61000 | 1000 | 960 | 191-914 | 455 | 5-50 | 2.3 | 18 | 3900×2060×2950 | 5000 |

| YRB-61200 | 1200 | 1160 | 191-914 | 455 | 5-50 | 2.3 | 22 | 3900×2260×2950 | 5800 |

Related products

Send Message

Most Recent

More

Other Products

Videos