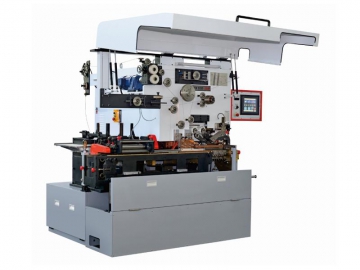

NEW DODO-300H Automatic Canbody Welder

Request a Quote

This automatic canbody welder is designed to complete high precision rounding and welding processes for the production of three-piece metal can bodies. The production output of this welder is 150 cans/min to 300 cans/min depending on the height of different cans.

Features

- This automatic canbody welder is equipped with an easy to use interface, PLC system, and servo system.

- Its static variable frequency power source provides stability and energy savings.

- The special rounding device can process various types of tinplate.

- The copper wire profiling roller and Z-rail are made of wear-resistant ceramics

- Remote control system and weld seam detection system are optional.

Technical Specifications

| Welding speed | 48m/min(max) |

| Production output | H133mm: 300cans/min(Max) |

| H180mm: 240cans/min(Max) | |

| H240mm: 180cans/min(Max) | |

| H300mm: 150cans/min(Max) | |

| Can inner diameter range | Φ52~Φ99mm |

| Height range | 100~320mm |

| Welding points distance | 0.5~0.9mm |

| Overlap width | 0.25~0.5mm |

| Sheet thickness | 0.16~0.30mm |

| Temper | T2.5~DR8 |

| Wire diameter | Φ1.24~1.38mm |

| Electrical mains | Three phase Voltage: 380V |

| Frequency: 50Hz | |

| Power consumption: 45kw | |

| Welding frequency | 220-450Hz |

| Cooling water | >0.4MPa, 12-18℃, 50L/min |

| Air pressure&consumption | >600L/min, >0.6MPa |