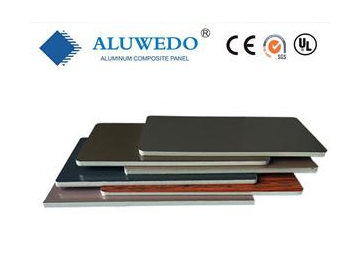

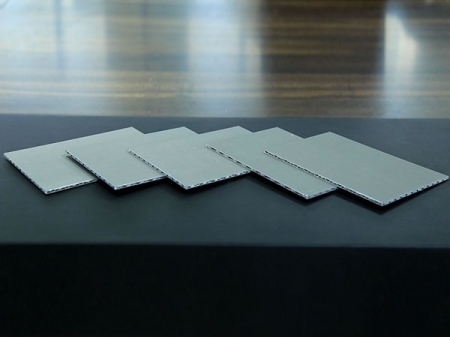

A2 Fire Resistant Aluminum Composite Panel, ACP Panel

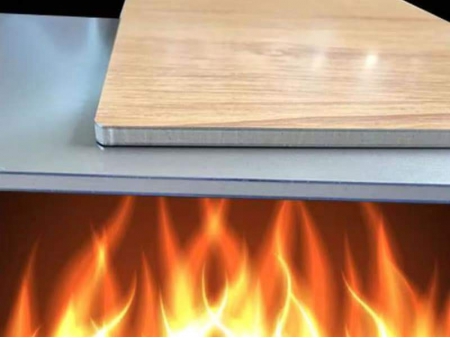

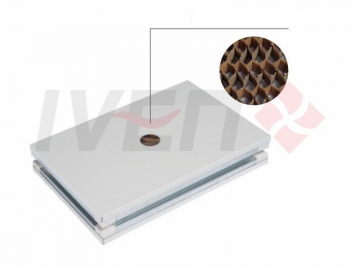

Aluwedo® A2 fireproof Aluminum magnesium composite panel (AMCP) is made from one layer of natural inorganic mineral material core and two layers of anti-scratch high-strength aluminum plates, between the 2 of which there is a special adhesive film, manufactured by constantly solidified and laminated under high temperature. The middle core is natural inorganic mineral materials, such as magnesium hydroxide, aluminum hydroxide, talcum powder, and light calcium carbonate, etc. All of them are green flame-retardant inorganic materials with multi-function of retarding, and suppressing smoke. For example, Magnesium Hydroxide - (Mg(OH)2), will decompose to absorb the caloric of burning articles only when the temperature reaches 340~490℃.

Raw Material

a. High strength aluminum alloy A3003, A5052

b. PE core material: fireproof A2 Noncombustible inorganic materials

c. Surface coating: PE, FEVE, PVDF coating, and adhesive film from Dupont

Specifications and Dimension

a. Thickness: 4mm

b. Width: 1000-1550mm,

Recommended width: 1220, 1500mm

c. Length: up to 5800mm

Recommended length: 2440mm, 3050mm, 4050mm

d. Aluminum thickness: 0.3~0.5mm

e. *Custom width and length available upon request (subject to the minimum order quantities)

| Thickness | 4 mm |

| Thickness of Aluminum layers (mm) | 0.5 |

| Weight (kg/m²) | 7.5 |

| Width (mm) | 1000 / 1220 /1250 / 1500 / 1575 / 2000) |

| Section modulus | DIN 53293 | [cm³/m] | 1.75 |

| Rigidity | DIN 53293 | [kNcm²/m] | 2400 |

| Alloy / temper of Aluminium layers | EN 573-3 EN 515 | A3003H18 | |

| Modulus of elasticity | EN 1999 1-1 | [N/mm²] | 70.000 |

| Tensile strength of Aluminium | EN 485-2 | [N/mm²] | Rm ≥ 130 |

| 0.2 % proof stress | EN 485-2 | [N/mm²] | Rp0,2 ≥ 90 |

| Elongation | EN 485-2 | [%] | A50 ≥ 5 |

| Linear thermal expansion | EN 1999 1-1 | 2.4 mm/m at 100ºC temperature difference | |

| Core | |||

| Mineral filled polymer | |||

| Surface | |||

| Coating | Fluorocarbon (e.g. PVDF Kynar 500) | ||

| Coating thickness (um) | >32 (3 coating) > 25 (2 coating) | ||

| Gloss (initial value) (%) | EN 13523-2 | 30-60 | |

| Pencil hardness | EN 13523-4 | HB-F | |

| Standard | China | Germany | USA | France | UK | Japan | Russian |

| Burning degree | GB/T8627 | DIN4102 | ASTM E84 | BS 476 | NFF16-101 | NFF K6911 | 30244-94 |

| Few | A | A1, A2 | NC | 0 | M0 | 1 | T1 |

| Minor | B1 | B1 | A | 1 | M1,M2 | 2 | T2 |

| Normal | B2 | B2 | B,C | 2,3 | M3 | 3 | T3 |

| Serious | B3 | B3 | 4 | M4,M5 | ~ | ~ |