Duct LineⅡ, Automatic Rectangular Duct Blanking System

Request a Quote

Automatic rectangular duct blanking systems lower labor costs and are used to precisely cut material to the desired length, thus completing material preparation segments. Compared to a manual measuring and cutting process, our automated production line is more precise, providing a cleaner cut that saves labor and increases productivity.

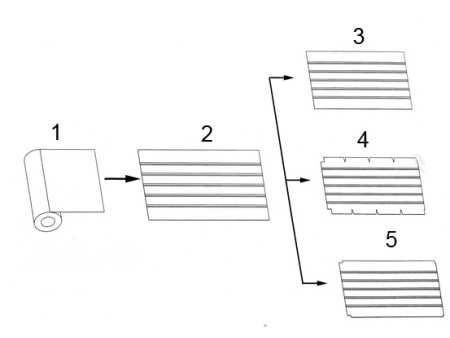

The duct line II consists of the material compartment, duct beader, sheet shearing machine, and angle pressing machine.

Advantages:All electronics are computer controlled, and a close loop system is used for production stability and precision. The maximum working speed is10m/min, and the length tolerance is ±0.5mm, with a diagonal line tolerance of ± 0.8mm.

Workflow:- Uncoiling

- Leveling&Bending Grooving

- Customized Cut-off

- Notched "V"and "口" and Shear for C&S or TDF Flange

- Notched "口" and Shear for C&S or TDF Flange

| Model | SBAL-II-1250 | SBAL-II-1550 |

| Thickness | 0.5-2.0mm | 0.5-2.0mm |

| Max. width | 1250mm | 1550mm |

| Max. feeding speed | 18m/min | 18m/min |

| Max. load of decoiler | 8000kg | 8000kg |

| Power | 9.2kW | 9.2kW |

| Machine weight | 3000kg | 3500kg |

| Dimension for duct forming machine | 1900x1800x1400mm | 1900x2100x1400mm |

| Decoiler | 2300x1750x1650mm | 2300x2050x1650mm |

| Voltage | 380V/3-phase/50Hz | |