470T Paper Folding Machine

The KMD 470T paper folding machine is used for folding paper in different sizes and thicknesses. It can achieve 2, 4, 6, 8, or 10 times parallel folding, and is capable of carrying out roll fold, Z fold, and inward half folding, outward half folding and other folding methods. The maximum size of paper that can be accessed is 470*750 mm.

The paper folding machine is widely used for folding of various printings, such as brochures, manuals, newspapers, and more, and can do so on a variety of paper types, including plain paper, plate-making paper, recycled paper, double-adhesive paper, drawing paper and more.

Product ListAt present, the combination of the main buckle plates, the tail buckle and folding knife system is:

- Feeder system

The feeder system is composed of a fan and a feeder head. The fan has two air outlets: one suction and one blower. The wind is regulated by an air valve, and there are two air filters on the fan side. Just opening the air filter once a week for cleaning ensures the paper remains clean.

The feeder head sucks the paper in single pieces through a suction process, then uses a vacuum roller to feed the paper into the conveyor belt.

- Conveying system

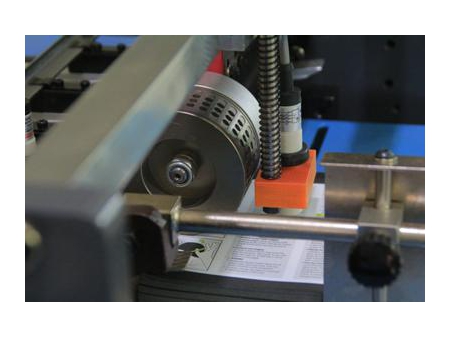

The conveyor system uses a rotating shaft to drive the belt to transport the paper. There is a row of paper balls placed above each conveyor belt, and these will press on the paper to ensure the paper remains smooth on the conveyor belt. - Folding system

The folding and forming system is mainly composed of a folding buckle and a gluing roller to achieve a certain folding effect. It is the detecting sensors who detects the paper and controls the electronic knife to fold. - Paper Stacking system

The delivery tray receives the folded paper through the conveyor belt and stacks the paper neatly and orderly. - Tail buckle feeding table

The tail buckle feeding table ensures paper moves smoothly from the main unit to the tail buckle, effectively controlling the speed and position of the paper entering the equipment, and reducing the number of defects.

- Tail buckle: If the number of buckles is not enough, you can configure the tail buckle to increase the number of folds and folding method.

- Electric control knife: realizes the paper’s last half folding.

- Tail buckle transition table: a transition device that can transport hard paper to the tail buckle. If the paper is too thick, the device will press it in the middle.

- Vertical paper stacker: Align the paper and arrange it neatly.