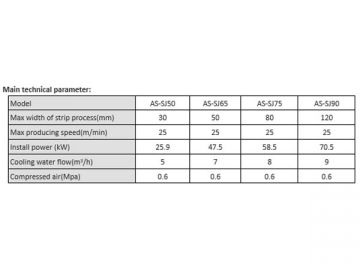

TPV,PVC automobile sealing strip extrusion line

Automobile Sealing Strip Extrusion Line / Sealing Strip Extrusion Line / Sealing Strip Extruder

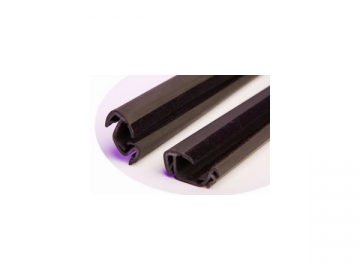

An automotive seal strip is one of the most important components in a car, as it is used in doors, windows, car bodies, skylight, motor racks, trunks and other parts for sound insulation, protection against dust, waterproofing and shock absorption.

The automobile sealing strip extrusion line uses a Kingswel Machinery Baochong Extrusion designed high performance single screw extruder and multi-extrusion. It is equipped with a precision mold and auxiliary lines which are used to process different automotive seal strip materials, including PVC/SVC, TPE (TPV, TPO, TPU) and different types (hard and soft, hard/soft combination, lined with an alloy frame, metal fixture, and tongue shaped car seat buckle). This production line is equipped with a gluing machine, flocking machine and drying rod to meet different requirements for automotive interior flocking strip production. By replacing a corresponding screw barrel, this production line can also be used to process seal strips used in a wide array of mechanical device applications.

Through continuous cooperation with high-end users, we have been able to carry out further research on advanced machinery and technology. Combining that with original Taiwanese extrusion technology processes and our long term research and development of polymer seal strip extrusion processes, we have developed a line of complete, highly efficient TPV seal products that are increasingly replacing rubber seal products. We have exceeded expectations and have expanded the shape controlling effects and capacity of all finished products.

-

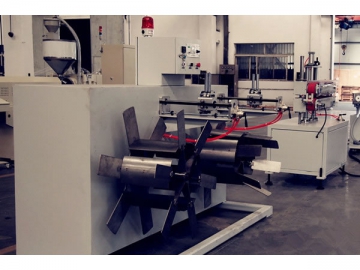

Extruders

Extruders -

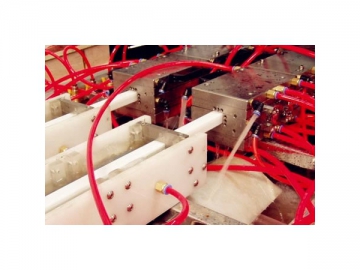

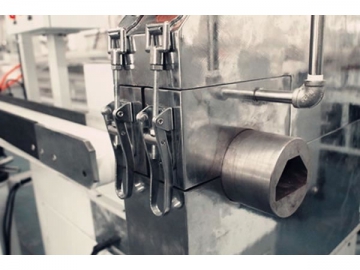

Die head

Die head -

Calibration tools

Calibration tools

Other Equipment in the Sealing Strip Extrusion Line

-

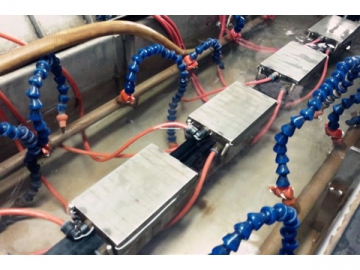

Calibration cooling tank

Calibration cooling tank -

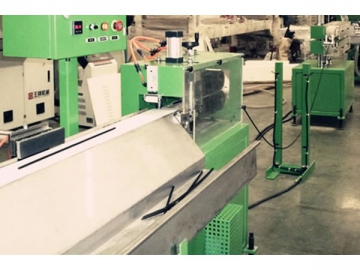

Puller

Puller -

Cutter

Cutter -

Cutter

Cutter

In recent years, we have increased our involvement in the research and development of the domestic market, and have earned recognition and praise from well-known companies including Saargummi, JYCO, Vintech, Kinugawa, Toyoda Gosei, INOUE, TSUCHIYA, and Great Wall Motor.

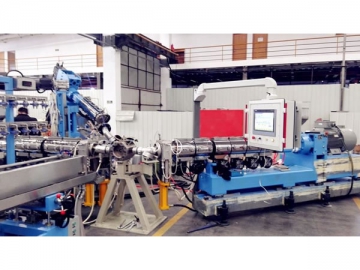

Case show:

End-user: Saargummi

Project start date: 2014

Machine line: TPV sealing strip extrusion line, 4 extruders co-extrusion

Machine line quantity: 1 line

Picture show:

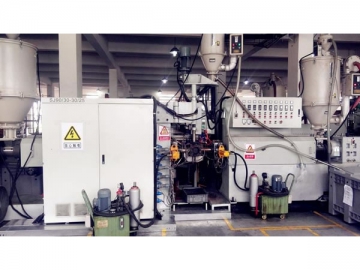

End-user: Saargummi

Project start date: 2007

Machine line: TPV sealing strip extrusion line, 3 extruders co-extrusion

Machine line quantity: 3 lines

Picture show: