Drill Collar

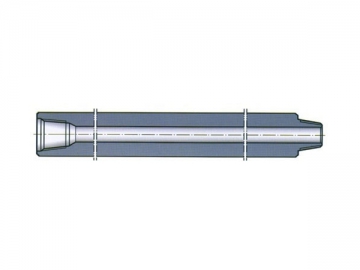

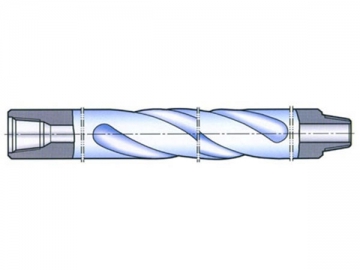

Owetech drill collars are manufactured under strict conditions in order to meet API Spec7-1 and SY5411 standards. Our spiral drill collar is made from high quality steel with an IF surface heat treatment. The thread root of the drill collar and the concave base of the collar elevator are formed by a cold rolling technique. This process reduces the risk of crack formation and increases the bearing pressure of the upper radius. All screw threads undergo a phosphorization process or copper plating to increase corrosion resistance.

These drill string components are designed with grooves on the collar slip and elevator according to user requirements. The grooves add a level of safety during oil drilling operation in the absence of a lift joint and secure grip. The size and shape of the slip groove and elevator groove are consistent with API Spec 7-1 standards. We can also provide steel or plastic inner ring thread protectors according to user requirements.

Specification| Drill collar Number | O.D. | I.D. | Length | Bevel diameter | Ref bend Strength Ratio | ||

| (mm) | (in) | (mm) | (in) | (mm) | |||

| 79.4 | 3 1/8 | 31.8 | 1 1/2 | 9150 | 76.2 | 2.57:1 | |

| 88.9 | 3 1/2 | 38.1 | 1 1/2 | 9150 | 82.9 | 2.42:1 | |

| 104.8 | 4 1/8 | 50.8 | 2 | 9150 | 100.4 | 2.43:1 | |

| 120.6 | 4 3/4 | 50.8 | 2 | 9150 | 114.7 | 2.58:1 | |

| 127 | 5 | 57.2 | 2 1/4 | 9150 | 121 | 2.38:1 | |

| 152.4 | 6 | 57.2 | 2 1/4 | 9150&9450 | 144.5 | 2.49:1 | |

| 152.4 | 6 | 71.4 | 2 13/16 | 9150&9450 | 144.5 | 2.84:1 | |

| 158.8 | 6 1/4 | 57.2 | 2 1/4 | 9150&9450 | 149.2 | 2.91:1 | |

| 158.8 | 6 1/4 | 71.4 | 2 13/16 | 9150&9450 | 150 | 2.63:1 | |

| 165.1 | 6 1/2 | 57.2 | 2 1/4 | 9150&9450 | 154.8 | 2.76:1 | |

| 165.1 | 6 1/2 | 71.4 | 2 13/16 | 9150&9450 | 154.8 | 3.05:1 | |

| 171.4 | 6 3/4 | 57.2 | 2 1/4 | 9150&9450 | 159.5 | 3.18:1 | |

| 171.4 | 6 3/4 | 71.4 | 2 13/16 | 9150&9450 | 159.5 | 2.37:1 | |

| 177.8 | 7 | 57.2 | 2 1/4 | 9150&9450 | 164.7 | 2.54:1 | |

| 177.8 | 7 | 71.4 | 2 13/16 | 9150&9450 | 164.7 | 2.73:1 | |

| 184.2 | 7 1/4 | 71.4 | 2 13/16 | 9150&9450 | 169.5 | 3.12:1 | |

| 196.8 | 7 3/4 | 71.4 | 2 13/16 | 9150&9450 | 185.3 | 2.70:1 | |

| 203.2 | 8 | 71.4 | 2 13/16 | 9150&9450 | 190.1 | 3.02:1 | |

| 209.6 | 8 1/4 | 71.4 | 2 13/16 | 9150&9450 | 195.7 | 2.93:1 | |

| 228.6 | 9 | 71.4 | 2 13/16 | 9150&9450 | 212.6 | 3.17:1 | |

| 241.3 | 9 1/2 | 76.2 | 3 | 9150&9450 | 223.8 | 2.81:1 | |

| 247.6 | 9 3/4 | 76.2 | 3 | 9150&9450 | 232.8 | 2.57:1 | |

| 254 | 10 | 76.2 | 3 | 9150&9450 | 237.3 | 2.81:1 | |

| 279.4 | 11 | 76.2 | 3 | 9150&9450 | 266.7 | 2.84:1 | |

| O.D. | Cutting depth | Lead ±25.4 | ||

| (mm) | (in) | A(mm) | B(mm) | (mm) |

| 86 | 3 3/8 | 3.5±0.79 | 679 | |

| 98.4 | 3 7/8 | 4.0±0.79 | 914 | |

| 101.6 ~ 111.1 | 4 ~ 4 1/8 | 4.8±0.79 | 914 | |

| 114.3 ~ 130.2 | 4 1/2 ~ 5 1/8 | 5.6±0.79 | 965 | |

| 133.4 ~ 146.1 | 5 1/4 ~ 5 3/4 | 6.4±0.79 | 1067 | |

| 149.2 ~ 161.9 | 5 7/8 ~ 6 3/8 | 7.1±1.59 | 1067 | |

| 165.1 ~ 177.8 | 6 1/2 ~ 7 | 7.9±1.59 | 1168 | |

| 181.0 ~ 200.0 | 7 1/8 ~ 7 7/8 | 8.7±1.59 | 5.6±0.79 | 1626 |

| 203.2 ~ 225.4 | 8 ~ 8 7/8 | 9.5±1.59 | 6.4±0.79 | 1727 |

| 228.6 ~ 250.8 | 9 ~ 9 7/8 | 10.3±2.37 | 7.1±1.59 | 1829 |

| 254.0 ~ 276.2 | 10 ~ 10 7/8 | 11.1±2.37 | 7.9±1.59 | 1930 |

| 279.4 | 11 | 11.9±2.37 | 8.7±1.59 | 2032 |