Lateral Move System (Hose Feed)

A lateral move system using a hose feed works in a linear movement to irrigate a rectangular area. Unlike center pivot systems, where the area irrigated depends only on the length of the machine, the area irrigated by the lateral system is determined by system length and travel distance.

Water is fed to the irrigation system by a flexible hose attached to the machine. The size of the hose is 6’ and 8’. The length can stretch from 1 span to 7 spans, though not more than 7 spans because of the hose weight limitation 450m length. The hose feed system requires hydrants and an underground pipeline.

The lateral move center is the only irrigation machinery which can water all of the land. In square patches of land, each span is parallel with the land so there are no blind angles and the irrigation ratio increases to 99%.

Lateral move center

Leg angle size: L4"×4"

Riser: diameter 8" thickness 1/8"

Elbow: diameter 8" thickness 1/8"

A special design forms a solid anchor for long systems.

Control panel

Main breaker

Control transformer

Start stop switch

Main contactor

Monitoring indicators

Forward / reverse contactors rated 600v at 30 amps

Fuses – 30 amps

Lightning arrestor

System monitors

Control power

Pressure

Last tower movement

Control circuit power

Safety circuit status

Reverse control circuit

Forward control circuit

Pump control circuit

Incoming 380V power

Our main control also supports

No water start stop

Running direction (auto-stop/auto-reverse)

Speed adjustment

Under voltage relay

Over current relay

Emergency stop

Low water pressure shut off

2. Diesel Generator

We supply a range of diesel generators from 6 to 20kw for pivots and we can supply small diesel generators. In addition, we are able to supply any spare parts for these generators as well. If you need replacement or spare parts for these generators, please contact us.

Model No.: PF15GF

Prime Power (kw/k VA): 15/19

Standby Power (kw/k VA): 16.5/20.9

Engine Model: 4L22BD-4

Alternator Model: FD1E

Dimensions (mm): 1360×560×885

Weight (kg): 420

3. Spans

Metallic zinc-coated spans are installed on intermittent towers, each with two wheels, an axle drive unit with electric gear motor, and gearboxes on wheels; the electronic block of the system of the equalization and checking.

The truss design is the most important part of pivot irrigation systems. That’s why Rainfine precisely calculates the structural mechanics and test are pivot systems in tough conditions. Our pivot structures are durable enough to withstand 20 years of work without bending or breaking.

Two pipe options

1. Galvanized pipe 8", 6 5/8", 5 9/16"

2. Galvanized pipe with poly lining 8", 6 5/8", 5 9/16" for special water

Galvanizing Kettle

Inside Dimension: 14,000 long ×1,200 wide × 2,000 mm deep

By W. Pilling of Riepe, Germany, the world’s leading kettle manufacturer.

50mm wall thickness, European Special Grade Plate (see analysis below)

Typical Analysis: C, .08%; Mn, .5%; P, .02%; S, .02%; Si, traces only

Zinc Volume of Kettle: 90 tons

Weight of Kettle: 25,150 kgs

Quality standards: BS-729, ASTM-A123

The flexible joint design makes the pivot strong enough and flexible enough to encounter rolling or hilly terrain while in motion. Because the aluminum coupler will break if the spans are not properly aligned, causing water to leak and water pressure to drop, we’ve designed the control panel to switch off the system and stop the machine when the water pressure lowers. Rubber pipe fittings reduce water friction and resistance.

We use a high frequency electric heating system to heat both ends of the steel rods and a head forging machine to form them. When the rod is cut, the steel rod and the headed part have the same molecular makeup. This truss rod can withstand 60,000psi. We use 22mm diameter rods instead of 19mm, making our truss rods stronger than others on the market.

Two options of coupler

1. Standard couplers

2. Universal couplers

Gear box two options

1. Cummins standard (left):

Material: Grey Iron HT250

Shaft Material: high-strength forged steel

Worm and gear pressure angle is 14 1/2 degree

2. Rainfine heavy duty (right):

Material: Ductile Iron HT300

Shaft Material: Steel 45

Worm and gear pressure angle is modified

Significant improvement over standard models

Specially designed for use in warmer climates where the pivot is used over 300 days per year

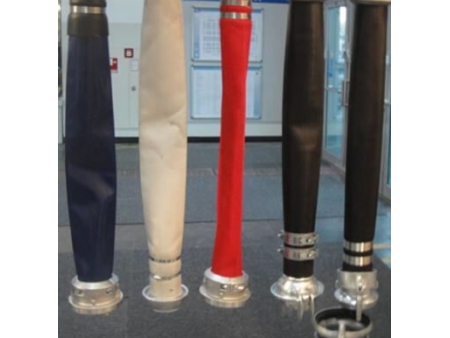

Tire two options

1. Rubber tire:

11.2×38: Good clearance and flotation

14.9×24: Tubeless tire 4ply, for heavier and longer spans

16.9×24: For longer spans more flotation

2. Plastic tire:

Rim: 10×38 with plastic pads (16 pcs×4kgs each)

Similar size with 14.9×24 rubber tire

Never flat / UV protection

Pad replacement / Non maintenance

Gooseneck: M × M, M × F, M × B, Furrow arm and standard

We use automatic welding to make high quality and uniform span pipes. Using form drill technology developed in Germany gives gooseneck pipes a strong connection to pipe outlets, reducing any damage to the gooseneck when the sprinklers vibrate.

Tower box

Contactor rated 600V at 16 amp min.

Alignment switches rated 277V at 15 amp tested to 10,000,000 cycles.

On-off switch rated 600V at 10 amps.

Cable specification

4# 14 gauge, 6# 18 gauge

4# 12 gauge, 6# 14 gauge

4# 10 gauge, 6# 14gauge

Inner PVC cover 30 mil thick

8 mil aluminum shield

Outer high-density polyethylene cover is 15 mil thick

Sunlight resistant

Moisture and dirt protection

4. Overhang

The high yield strength overhang cable is used in longer overhangs. This design helps farmers to increase their yield with less investment.

Pipe size:

Φ141mm×3mm

Φ102mm×3mm

Overhang length:

6.70/13.41/20.12/26.82m

Cable size

RF38213"O" Φ6×5.893M

RF38211"O" Φ6×19.526M

RF38210"O" Φ9×13.106M

RF38214"OW" Φ6×5.435M

RF101623"U" Φ6×6.858M

RF38209"OU" Φ9×25.133M

RF38215"OU" Φ9×14.376M

RF38212"O" Φ6×26.054M

5. End Gun

Corner control system for end gun

When the pivot moves near corners, the end gun will switch on/off by solenoid valve so it can water more area. This valve is controlled by switches in the pivot center.

6. Sprinkler

The vast differences in crops, soils, farming practices and climatic conditions worldwide, coupled with the availability of water and energy resources, requires a range of center pivot sprinkler performances. Our sprinklers are designed to simplify the variety of choices into one basic and versatile group of center pivot products.

D3000

A fixed-spray sprinkler which produces a variety of patterns depending upon specific spray plates;

Flip-over dual spray allows easy conversion of spray patterns;

Choose spray plate options to germinate, irrigate, or chemigate;

Optional hose drag adapter for Low Energy Precision Application - LEPA;

Part circles available.

S3000

Gentle spray at low pressure;

Utilize a free-spinning acting to produce a gentle, rain-like water pattern;

Designed for more sensitive crops and soils;

Superior uniformity with better overlap and lower application rates;

Crop-guarded body for low energy;

Part circles available.

R3000

A greater spray radius from rotating streams equates to lower average application rates, longer soak times and less runoff;

Increased overlap from adjacent sprinklers improves uniformity;

Reduces wind drift and evaporative loss;

Part circles available.

O3000

Outstanding uniformity at low operating pressures;

Unassembled bracket eliminates debris hang-up and water-pattern misting that’s common to conventional sprinklers;

Long service life, reliable operation and durability;

Excellent water application, 10-20 PSI operating pressure;

Wind resistant, maximum water and energy conservation.

LDN

Minimized losses to wind drift, evaporation and runoff;

Multiple deflector pad design;

Sturdy design for traveling through tall crops;

Low pressure – 6 to 15psi;

Chemigation pads produce an upward spray under the crop canopy;

Bubbler pad applies water in a gentle, aerated pattern ideal for direct-to-furrow irrigation;

i-Wobs

Unique off-center rotary action, outstanding uniformity;

Gentle, rain-like application;

Excellent spray distance;

Low pressure operation from 10 to 20psi saves energy over the course of a year.

Xi-Wob

Large area of coverage

Ultra low pressure

Easy to clean and easy to change the nozzle

Droplet size needed for type of soil

Uniformity affects

Application intensity

Excellent spray distance

Super Spray

Wide variety of color-coded deflector pads to customize distribution pattern;

Full 360 degree spray pattern;

Low-pressure operation: 6-25psi;

Chemigation pads and hose barb adapter available.

7. Chemical Injector

The chemical injector has a capacity of 85 to 500 LPH and a maximum pressure of 12 bar. Measuring accuracy is /- 2% with a flow rate of 10%–100%.

8. Multiple Filters

Though pivots only need one filter, multiple filters are good optional parts for when one filter fills too quickly with dirt. A cluster system composed of several filters can often be used for more than one pivot. For more effective drip irrigation, clients can choose segmented filter system.

9. Auto Reverse and Stop System

Due to factors such as the terrain, barns and houses, and other obstacles, the pivot may not be able to work a full circle. An automatic stop and reverse controls the pivot to avoid collision. A barricade on the last tower of the pivot works so that when hit by a sensor arm, the pivot will stop and reverse automatically. This system includes a control box, sensor arm, traverse arm, cable and springs, and collision prevention.

10. Shipment

Each span is packed into one wooden box with a clear packing list and instructions for easy installation. All wooden boxes are durable for safe exporting. A 500m fixed pivot (9 spans) can be loaded into a 1×40’ HC container.

11. Installation

We will send our engineers to supervise installation. Normally one 7-span pivot needs eight people working one week for installation.

12. Spare Parts and Guarantee

We will ship 2% of spare parts together with the equipment in the container, whichever of the spare parts were listed on the contract. Our local representatives or dealers will help farmers replace damaged parts when necessary.

Guarantee:

1 year for electric equipment

10 years/10,000 working hours for gearboxes and gear motors, whichever expires first

20 years for galvanized equipment against corrosion

3 years for tires and rims