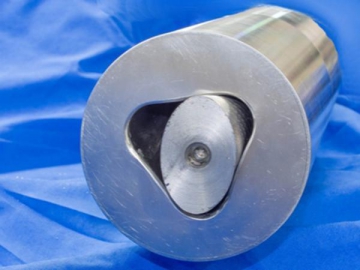

Progressive Cavity Pump Stator

- Metal stator

- PTFE stator

- Rubber stator

A stator is one of the most important components to a progressive cavity pump, and is often divided into two types: a rubber stator, or a rigid stator. We offer customized stators according to actual field conditions and the transmission medium.

1. Rubber stator: Stators are a vulnerable part of progressive cavity pump. When the stator surface becomes worn, the sealing performance between the rotor and the stator decreases, which results in a decreased flow. Different rubbers, such as NBR, NBRH, HNBR, EPDM and FKM with corrosion resistance and high temperature resistance need to be chosen to suit different mediums.

2. Rigid stator: Rigid stators include a metal stator or PTFE stator. A rigid stator is recommended in specialized work environments, such as the transportation of hot oil, high temperature bitumen, high temperature heavy oil, concentrated acid or alkali, and a high concentration of chloride ions.

Features of rigid stator

1. It features a high temperature resistance- up to 300℃.

2. The rigid stator can bear a high pressure medium. They feature a small torque and a single stage pressure of up to 12 bar.

3. In a progressive cavity pump with the same flow, a pump with a rigid stator will be smaller than one with a rubber stator.

4. Metal stators feature a quick heat dissipation, no abrasion and a longer service life.

5. PTFE stators are suitable for strong acidic and alkaline environments, as well as mediums with a high chlorine content.

| Material | Corrosion resistance | Swelling resistance | Abrasion resistance | High temperature resistance | Temperature range | Suitable Application |

| NBR | general | good | general | general | +110℃ | Petroleum, sewage, food and beverage, chemical, or paper making industry |

| NBRH | good | excellent | good | general | +120℃ | Oil refining, chemical, waste water |

| EPDM | good | poor | good | general | +120℃ | Chemical industry, chemical reagent, paper making |

| FKM | excellent | excellent | poor | excellent | +180℃ | High temperature and corrosive fluid |

| HNBR | excellent | good | good | excellent | +170℃ | Petroleum, petrochemical and chemical industry |

| PTFE | excellent | excellent | poor | excellent | +230℃ | Acid & alkali and other strong corrosive medium, high temperature and high hygiene requirements of the food and beverage industry |

Note: All information above can be combined based on specific requirements, the particular medium that needs moving, and the working conditions. Please contact us for more details.

Weifang Subtor as a German Subtor invested company in China, offers wide range of progressive cavity pumps and pump stator components. We provide wear-resistant NBR stator, NBRH stator, EPDM stator, FKM stator, HNBR stator, PTFE stator, etc. With German supported technology and rich marketing resources, Subtor provides quality PCP pumps as well as stator parts for global clients.