Variable Displacement Axial Piston Pump/Bent Axis Pump/Axial Piston Motor/Bent Axis Motor, A6V

Axial piston pumps and motors A6V are used as components of bent axis, with the displacement to be variable and no more than 500mL/r. A6V axial piston motors and pumps are widely applied in industrial construction and engineering projects.

Main Features

1. High-performance rotating components feature automatic alignment operation, low peripheral speed and high efficiency are adopted

2. Highly durable roller bearings and ball bearings

3. The driving shaft can bear radial load without getting the valve and pump damaged

4. The adoption of fire-resistant hydraulic oil enables the valve and pump to be applied in explosion-protection projects

5. The bent axial pump and motor features low noise

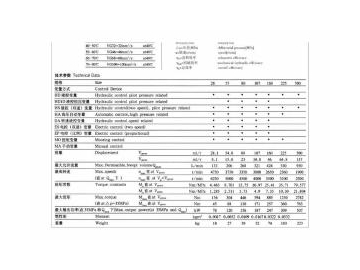

Technical Parameters

For more details, please download the PDF file

Precautions for Use

1. To ensure the working efficiency, choose the right hydraulic oil for your specific application. Arguably, all of the base oils are applicable for axial piston components, with the water, viscosity, and temperature of the medium decide where they are applied in specifically. Other factors like oxidation, corrosion protection and material compatibility should also be taken into consideration.

2. An effective filtration operation is required for the medium to guarantee service life of the equipment. Size of the solid particle in the oil should be limited by:

Level 9 - in line with NAS1638;

Level 6 -in line with SAE;

Level 18/15 - in line with ISO/DIS 4406;

Cleanliness of the high-temperature should be no lower than:

Level 8 - in line with NAS1638;

Level 5 - in line with SAE

Level 17/14 - in line with ISO/DIS 4406

3. Users must know the working temperature related to the ambient, like the temperature in closed and open loop if they are to choose the right hydraulic oil

4. Case temperature that may lead to a leakage is related to the pressure and rotating speed. It is higher than temperature of an open loop, any points of which should be no more than 90℃.

5. For special applications in extreme working conditions like ultra-high temperature, please tell us before you placing an order

6. Pressure at inlet port of the pump (absolute pressure) shouldn't be lower than 0.08MPa, and pressure at the outlet port (the max pressure inner the case) should be 0.2MPa. External force on the shaft seal shouldn't exceed pressure inner the case

7. Installation position: generally, for installing the hydraulic motor or pump, the upper edge of the case is required to be lower than the min level of the water in the cylinder. If there are any special needs, please tell us when you place an order.

Choose the Right Specification