Single Cylinder Hydraulic Cone Crusher

Application

The single cylinder hydraulic cone crusher with laminated crushing cavity and automatic control system can be used for medium crushing, fine crushing and superfine crushing. The single cylinder hydraulic cone crusher is widely used in gravel production, mining, coal mining, concrete mixing station, dry mortar, power plant desulphurization, quartz sand and other fields.

Applicable materials

Pebbles, granite, basalt, ironstone, marble, limestone, quartzite, diabase, iron ore, gold ore, copper ore and etc.

| Model | Cavity type | Max feeding size (mm) | Min feeding size (mm) | Installed power (kW) | Handling capacity (t/h) | |

| SC100S | C1 | 250 | 22 | 90 | 85-170 | |

| C2 | 200 | 19 | 90 | 70-130 | ||

| SC160S | C1 | 360 | 25 | 160 | 125-345 | |

| C2 | 300 | 22 | 160 | 108-305 | ||

| SC250S | C1 | 450 | 35 | 250 | 267-605 | |

| C2 | 400 | 29 | 250 | 225-515 | ||

| SC315S | C1 | 560 | 41 | 315 | 349-1050 | |

| C2 | 500 | 38 | 315 | 318-892 |

| Model | Cavity type | Max feeding size (mm) | Min feeding size (mm) | Installed power (kW) | Handling capacity (t/h) | |

| SC100 | F1 | 150 | 10 | 90 | 45-135 | |

| F2 | 90 | 10 | 90 | 43-118 | ||

| F3 | 50 | 6 | 90 | 36-71 | ||

| SC160 | F1 | 200 | 13 | 160 | 69-215 | |

| F2 | 115 | 10 | 160 | 57-184 | ||

| F3 | 75 | 8 | 160 | 63-126 | ||

| SC250 | F1 | 215 | 16 | 250 | 116-396 | |

| F2 | 140 | 13 | 250 | 97-328 | ||

| F3 | 70 | 8 | 250 | 95-252 | ||

| SC315 | F1 | 275 | 16 | 315 | 177-662 | |

| F2 | 175 | 16 | 315 | 162-552 | ||

| F3 | 85 | 13 | 315 | 195-401 | ||

| SC560 | F1 | 300 | 22 | 560 | 448-1512 | |

| F2 | 195 | 19 | 560 | 380-1373 | ||

| F3 | 90 | 13 | 560 | 357-912 | ||

| SC750 | F1 | 370 | 25 | 750 | 394-2181 | |

| F2 | 300 | 19 | 750 | 342-2020 | ||

| F3 | 230 | 16 | 750 | 267-1814 | ||

| F4 | 120 | 13 | 750 | 248-1165 | ||

| F5 | 85 | 10 | 750 | 185-1170 |

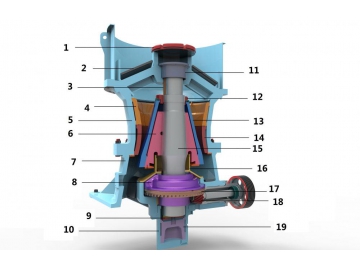

1. Top bearing cover

2. Upper frame guard

3. Top bearing

4. Upper part of concave liner

5. Upper frame

6. Head

7. Lower frame

8. Eccentric bushing

9. Bearing plate

10. Cylinder

11. Mainshaft protecting sleeve

12. Mantle locking nut

13. Mantle liner

14. Lower part of concave liner

15. Mainshaft

16. Dust seal

17. Gear

18. Roller bearing

19. Piston

- Hydraulic cone crushers with crushing cavity and laminated crushing principle can lead to intergranular fragmentation, so as to increase the proportion of cubes in the products and reduce jagged stones, and the size of products is more uniform.

- Double insurance control hydraulic and lubrication system: ensure overload protection and good bearing lubrication.

- High productivity and high crushing efficiency.

- Equipped with high performance wear-resistant liner, longer service life.

- Simple structure, low operating cost and easy to maintain.

- Automatic control system: using PLC+ touch control mode, monitoring temperature, pressure, current and other core parameters in real time, and automatic control to ensure the safe operation of the equipment.

- Various cavities, suited for different sizes of materials.

mining crusher, rock crusher, stone crusher, crushing machine, industrial crusher