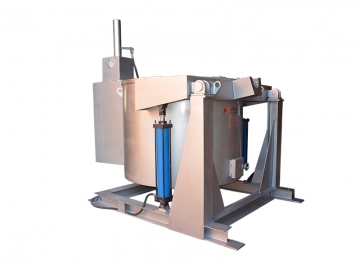

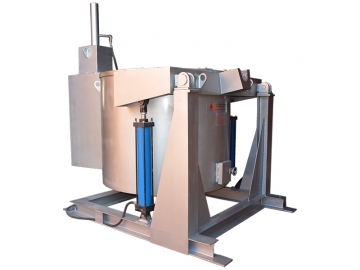

Gas Fired Ceramic Immersion Heaters for Hot Dip Galvanizing

As an automatic heating device, the gas fired ceramic immersion heater for hot dip galvanizing equipment mainly consists of pipe with ceramic sleeve imported from England and gas nozzle produced by German technology. The combustion system of the ceramic heater for galvanizing equipment comprises of gas nozzle, gas valve group, gas flow control valve, gas pressure measurement switch, air regulation device, ignition device, and draught fan.

The combustion system of the gas fired ceramic immersion heater is automatically controlled by a pulse controller, PID intelligent temperature controller, and automatic nozzle controller. An electric ignition device is used, and each nozzle controller comes with an automatic nozzle controller. The nozzle controller is used for detecting the ignition process and flame, and then the flame status signal will be transferred to the remote control system of the galvanizing equipment to achieve the flame-out protection function.

The automatic nozzle controller of the gas fired ceramic immersion heater is mounted in the on-site control cabinet. The nozzle controller will transfer the real-time signals to the remote control system which in return can activate the ignition, flame detection, signal treatment, and system operation. The LPG gas heater comes with a circulation reheating design, leading to a high heat efficiency of 60%~70%.

Specification of the gas fired ceramic immersion heater for hot dip galvanizing

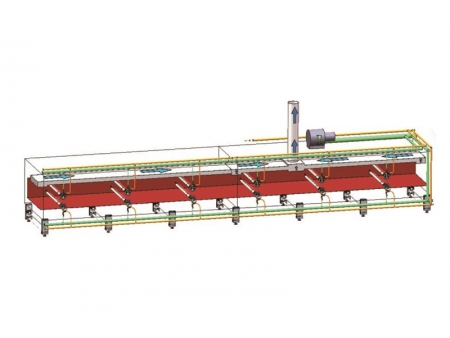

Application range: high temperature hot dip galvanizing of steel wire, fastener, electric power fittings

Operating temperature: 420℃~560℃

Power of each heater: 50kW~60 kW