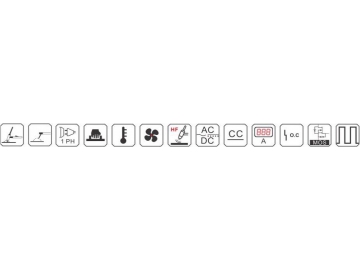

AC/DC Inverter Pulse TIG Welder, MOSFET Welding Machine

Main Parameters

Applicable Power Supply: Single Phase

Rated Input Voltage: 110V/220V

Rated Input Power: 2.7kW-4.9kW

Rated Input Current: 18.7A-55.9A

Open Circuit Voltage: 56V

Our MOSFET inverter AC/DC TIG welder is highly cost-effective. It supports DC power source generated through one converting process and AC power source obtained through two converting processes. To be more specific, incoming 50 or 60 Hz AC power first is rectified to DC and filtered and then is fed into the inverter to be converted back to high frequency AC, and then is fed to the main power transformer, where it is transformed into low-voltage, high frequency AC, and then be filtered and rectified to DC, which could be used directly for welding. In addition, it could be fed into the inverter again to generate AC suitable for welding if required.

The TIG welding machine can generate pulsed arc periodically, thus accommodating situations in need of higher welding quality. It also supports both TIG and MMA welding methods. It can be applied for welding a variety of metals including carbon steel, stainless steel, alloy steel, copper, titanium, etc.

Features- The MOSFET inverter adopted on the welding machine works with frequencies as high as 100KHZ, ensuring fast dynamic response.

- Both regular 2T and semi-automatic 4T modes are supported. In 2T mode, the operator will need to hold the 2T switch down during the whole welding process. While in 4T mode, the operator simply needs to toggle the torch switch on, let go and then weld.

- High frequency and high voltages are applied for arc striking, which is non-contact type. Therefore, the welding machine is more suited to weld thin workpieces.

| Model | TIG160ACDCP | TIG200ACDCP | TIG250ACDCP2 | TIG250ACDCP3 | TIG315ACDCP | |||||||||||||||

| Rated Input Voltage | 1P 110V | 1P 220V | 1P 110V | 1P 220V | 1P 110V | 1P 220V | 1P 110V | 1P 220V | 1P 110V | 1P 220V | ||||||||||

| Frequency | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | 50/60Hz | ||||||||||

| Welding Mode | MMA | TIG | MMA | TIG | MMA | TIG | MMA | TIG | MMA | TIG | MMA | TIG | MMA | TIG | MMA | TIG | MMA | TIG | MMA | TIG |

| Rated Input Power | 4.5KW | 2.7KW | 4.9KW | 3.0KW | 4.5KW | 2.7KW | 4.9KW | 3.0KW | 4.5KW | 2.7KW | 4.9KW | 3.0KW | 4.5KW | 2.7KW | 4.9KW | 3.0KW | 4.5KW | 2.7KW | 4.9KW | 3.0KW |

| Rated Input Current | 55.9A | 34.0A | 30.4A | 18.7A | 55.9A | 34.0A | 30.4A | 18.7A | 55.9A | 34.0A | 30.4A | 18.7A | 55.9A | 34.0A | 30.4A | 18.7A | 55.9A | 34.0A | 30.4A | 18.7A |

| Duty Cycle (40°C 10min) | 60%140A, 100%108A | 60%150A, 100%116A | 60%140A, 100%108A | 60%190A, 100%147A | 60%230A, 100%178A | 60%250A, 100%194A | 60%230A, 100%178A | 60%250A, 100%194A | 60%270A, 100%209A | 60%315A, 100%244A | ||||||||||

| Open Circuit Voltage | 56V | 56V | 56V | 56V | 56V | 56V | 56V | 56V | 56V | 56V | ||||||||||

| Rated Output Current Range | 10-140A | 10-150A | 10-140A | 10-190A | 10-230A | 10-250A | 10-230A | 10-250A | 10-270A | 10-315A | ||||||||||

| Efficiency | ≥80% | ≥80% | ≥80% | ≥80% | ≥80% | ≥80% | ≥85% | ≥85% | ≥85% | ≥85% | ||||||||||

| Power Factor | 0.73 | 0.73 | 0.73 | 0.73 | 0.73 | 0.73 | 0.93 | 0.93 | 0.93 | 0.93 | ||||||||||

| N.W | 22.3KG | 22.3KG | 22.8KG | 22.8KG | 34.0KG | 34.0KG | 34.0KG | 34.0KG | 35.0KG | 35.0KG | ||||||||||

| G.W. | 24.3KG | 24.3KG | 24.3KG | 24.8KG | 24.8KG | 37.0KG | 37.0KG | 37.0KG | 37.5KG | 37.5KG | ||||||||||

| Packing Dimension | 635×295×570mm | 635×295×570mm | 635×295×570mm | 635×295×570mm | 780×305×610mm | 780×305×610mm | 780×305×610mm | 780×305×610mm | 780×305×610mm | 780×305×610mm | ||||||||||

Customization

The appearance, welding current, product manuals and package of our TIG welding machine can be customized according to customer requirements.

- TIG Welding Torch

- Electrode Holder

- Earth Clamp

- Mask

- Hammer Brush

- PU Tubing