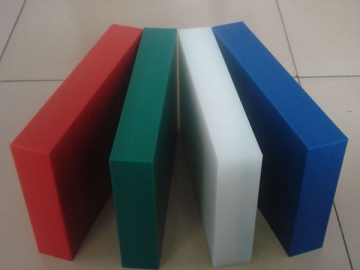

Plastic Wear Strip (HDPE Wear Strip / High Density Polyethylene Strip)

Size of Xinxing Plastic Wear Strips

Max. Length: 6m

Max. Width: 2.5m

Features of HDPE Wear Strips

Wear resistant

Lightweight

Durable

Corrosion and impact resistant

Great weather resistance

Easy to weld but difficult to bond

Applications of HDPE Wear Strips

Our plastic wear strips engineered from high density polyethylene are widely used as belt guides for conveyor belts of mechanical equipment especially mining machinery.

HDPE is a preferred engineering material for plastic profile manufacturing due to its abrasion resistance and durability. Therefore, thermoplastic profiles such as HDPE wear strips have a long service life and help protect machinery as well as goods being conveyed.

Color: white, black, grey, red, blue, green, yellow, etc.

Property data sheet of HDPE Wear strips| Property | Unit | Testing Method | Value |

| Molecular Weight | 1E6 g/mol | ASTM D6474 | 1-3 |

| Density | g/cm3 | ISO 1183-1 | 0.94-0.98 |

| Abrasion | % | ISO15527 | 100 |

| Dynamic coefficient of friction | ISO8295 | ≤0.15 | |

| Shore hardness | ISO868 | ≥63 | |

| Water absorption | % | ASTM D-570 | ≤0.1 |

| Temperature resistance | ℃ | -200 to 80 | |

| Elongation at break at 23 degree | % | ISO 527 | ≥200 |

| Melt Temperature | ℃ | 130-140 |

Related Names

HDPE Strip | HDPE Wear Strip | High Density Polyethylene Strip