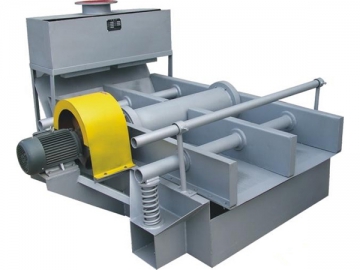

Centrifugal Screen

Capacity: 10~100 t/d

Improved from the CX series screen, our ZSL series centrifugal screen is used to screen a variety of pulps, including chemical pulp and wastepaper pulp. It is also used for the fine screening of stock for paper making machines. This centrifugal machine, also called a centrifugal sifter or centrifugal sieve, features a high screening efficiency, less pulp wastage, no clogging, a low energy consumption, small floor area, and easy operation and maintenance. It is now commonly used as pulp screening equipment for the pulp and paper industry.

| Items | Model | |||

| Screening area (m2) | 0.5 | 0.9 | 1.6 | 2.4 |

| Capacity (t/d) | 10 ~ 15 | 20 ~ 30 | 40 ~ 60 | 60 ~ 100 |

| Rotor size (mm) | φ324×538 | φ455×645 | φ610×880 | φ718×1130 |

| Rotor speed (r/min) | 750 | 575 | 485 | 450 |

| Inlet diameter (mm) | φ150 | φ200 | φ300 | φ345 |

| Screen holes diameter (mm) | 1.2 ~ 3.4 | |||

| Inlet consistency (%) | 0.8 ~ 3.0 | |||

| Outlet consistency (%) | 0.6 ~ 1.5 | |||

| Inlet pressure head (m) | 1.2 ~ 2.4 | |||

| Dilution water pressure (MPa) | 0.1 ~ 0.15 | |||

| Screen cylinder size (mm) | Ø340×470 | Ø475×600 | Ø635×800 | Ø747×1065 |

| Motor power (kW) | Y132M-4/7.5 | Y180L-4/22 | Y250M-6/37 | Y280M2-6/75 |

| Machine weight (kg) | 500 | 1290 | 2340 | 3630 |

| Dimension (L×W×H) mm | 2160×1630×700 | 2670×1850×970 | 3250×2380×1250 | 3590×2980×1460 |

Related products

Send Message

Most Recent

More

Other Products

Videos