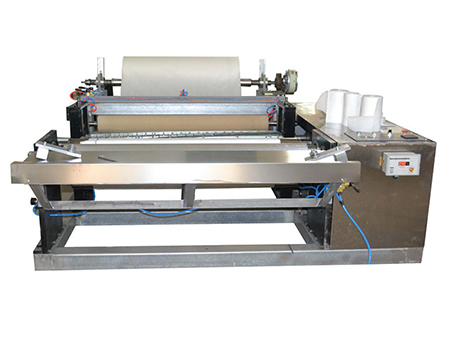

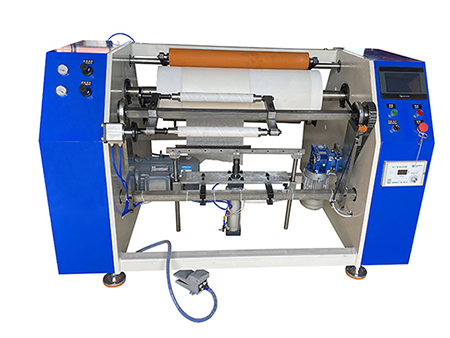

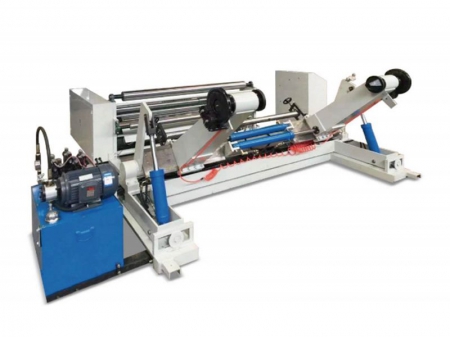

Kitchen Towel Production Line (With Rewinder, Slitter)

The HX-2600B Fully Automatic Kitchen Towel Production Line combines the and the : the former is responsible for printing, embossing and laminating paper, while the latter is used to cut paper rolls into desired lengths.

Controlled by a PLC, our automated paper production line just needs one operator, which means that more work can be produced at a lower labor cost, great for small or start-up paper manufacturers.

Features of kitchen towel machine

1. Our kitchen towel production line produces laminated kitchen towel by providing even gluing and laminating. A 1-color printer prints patterns and text on the paper. It is also able to manufacture toilet paper.

2. This paper converting equipment loads jumbo rolls pneumatically, and it will automatically alert operators to add paper cores when necessary. When there is no paper core or jumbo roll, it will stop production immediately.

3. Stepless speed controls the unwinding process, while the rewinding process is also regulated to avoid separation of paper and core.

4. The automatic kitchen towel production line is able to rewind and replace cores without stopping, and it will adjust production speed automatically during edge trimming, glue spraying, rewinding and paper core replacement.

Production Process of kitchen towel machine

Unwinding jump rolls - printing - embossing - gluing - laminating - perforating - rewinding - tail sealing - cutting

Technical Data of kitchen towel machine

1. Production speed: 120-180m/min

2. Jumbo roll width: ≤2600mm

3. Jumbo roll diameter: ≤1200mm

4. Jumbo roll weight: ≤800kg (other values shall be specified)

5. Paper weight: 13-20g/m2 for two-ply type, 25-40g/m2 for one-ply type

6. Finished paper roll diameter: 100-130mm

7. Finished paper roll width: 90-120mm for toilet paper, 200-220mm for kitchen towel

8. Perforation interval: 100-150mm for toilet paper, 200-220mm for kitchen towel

9. Power consumption: 15.6kW (380V/50Hz)

10. Machine weight: About 9 tons

11. Machine dimensions (L×W×H): 5.7×3.5×1.8m