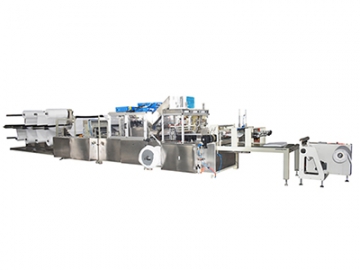

Semi Automatic Non-woven Bedding Making Machine, WFB-X900

Bedding Machine/ Fabric Cover Production Line/ Fabric Bag Machine

Main Introductions

This non-woven bedding making machine uses a double roll fabric feeder that seals the two fabric sheets automatically. This equipment is widely used in the production of bedding bags, appliance packaging, luggage caps, seat covers and many other items.

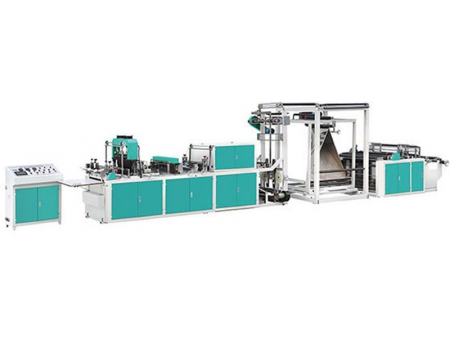

Advantages

1) Micro-computer control system, perfect combination of electro mechanical technology and ultrasonic sealing technology.

2) Stepping motor(servo motor control system can be selected and equipped)

3) Arbitrary fixed length

4) Accurate and stable photocell tracking

5) Stops automatically if the label is lost

6) Automatic punching, automatic counting and counting alarm

7) Heat-sealing decorative border

8) Automatic constant temperature, perfect and smooth sealing, with EPC control

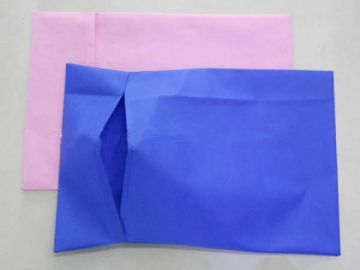

Product

1. Bedding use

2. Dust bag for luggage

3. Operating room use

| Model | WFB-X900 | WFB-X1200 |

| Max. Bag Making Width | 900mm | 1200mm |

| Bag Making Thickness Range | 20-60g | 20-60g |

| Max. Bag Making Length | 999mm | 999mm |

| Production Speed | 20-60pcs/min | 20-60pcs/min |

| Total Power | 5kw | 8kw |

| Machine Weight | 1t | 1.5t |

| Overall Dimensions | 4500*1700*1600mm | 4500*2400*1600mm |